Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

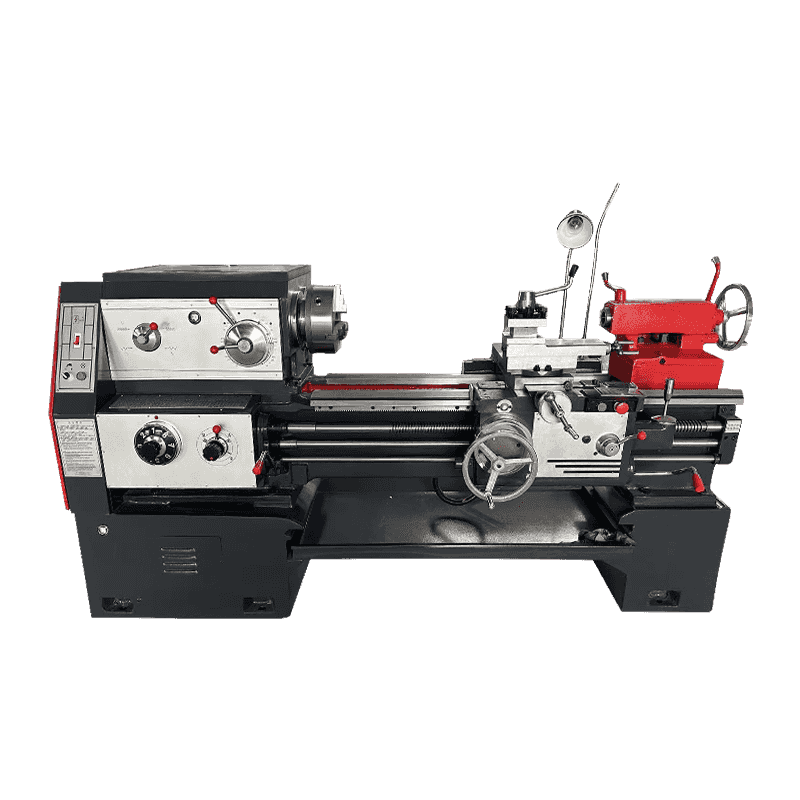

CK6180 low-noise CNC horizontal lathe

1. Machine tool headbox and bed. Tailstock. The pallet is scraped and researched manually, and the whole machine is tested by the ship, which can effectively guarantee the positioning accuracy of the Z-axis and X-axis, repeat positioning accuracy, backlash, and stability of the machine tool.

2. The machine tool adopts high-strength cast iron, added copper and knot special materials, bed guideway quenching depth of 3mm, effectively improving the wear resistance and stability of the machine tool.

3. The machine tool adopts centralized lubrication, headstock box circulating forced lubrication, for the hot weather in the south, to ensure the cleanliness of the headstock box and heat dissipation characteristics, effectively prolonging the service life of bearings and gears.

4. The machine tool spindle adopts Harbin bearings, spindle through-hole cp82mm, machine tool gears using precision grinding, effectively improve the hardness of the gear wheel, reducing the noise of the machine tool.

5. The machine tool adopts Hanjiang ball screws, Z-axis ball screws, and X-axis ball screws with tensile structure, which improves the accuracy of the workpiece machining cylindrical and internal hole size.

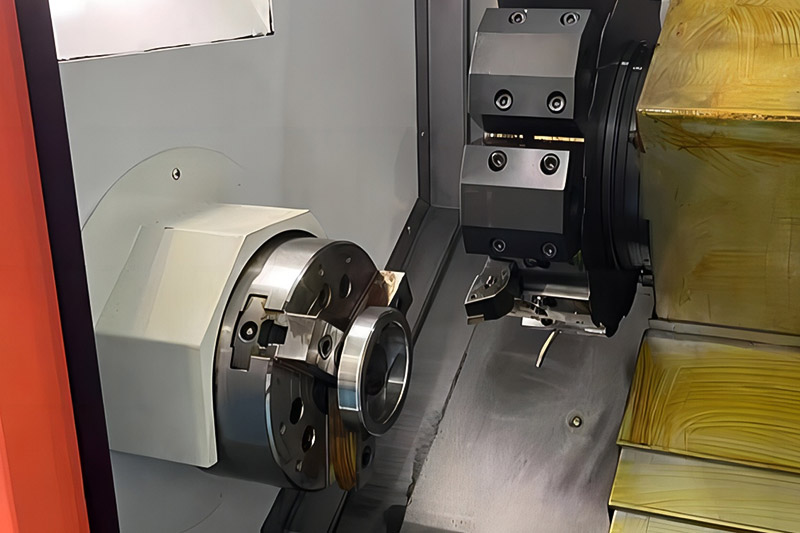

6. The machine adopts a four-station non-lifting electric tool holder. Tool shank size: 25x25mm.

7. Delixi brand electrical appliances

Production Information

Advantages of machine tools

1. Machine tool headbox and bed. Tailstock. The pallet is scraped and researched manually, and the whole machine is tested by the ship, which can effectively guarantee the positioning accuracy of the Z-axis and X-axis, repeat positioning accuracy, backlash, and stability of the machine tool.

2. The machine tool adopts high-strength cast iron, added copper and knot special materials, bed guideway quenching depth of 3mm, effectively improving the wear resistance and stability of the machine tool.

3. The machine tool adopts centralized lubrication, headstock box circulating forced lubrication, for the hot weather in the south, to ensure the cleanliness of the headstock box and heat dissipation characteristics, effectively prolonging the service life of bearings and gears.

4. The machine tool spindle adopts Harbin bearings, spindle through-hole cp82mm, machine tool gears using precision grinding, effectively improve the hardness of the gear wheel, reducing the noise of the machine tool.

5. The machine tool adopts Hanjiang ball screws, Z-axis ball screws, and X-axis ball screws with tensile structure, which improves the accuracy of the workpiece machining cylindrical and internal hole size.

6. The machine adopts a four-station non-lifting electric tool holder. Tool shank size: 25x25mm.

7. Delixi brand electrical appliances

Technical Parameter

| Item | Content | Unit | CK6180 |

| Processing scope | Maximum turning diameter on the bed skateboard | mm | Φ800 |

| Maximum turning diameter on a skateboard | Φ480 | ||

| Maximum processing length | mm | 1000 | |

| Maximum machining diameter | mm | Φ800 | |

| Principal axis | Chuck |

400mm Three Claw 630mm Four claws |

|

| The main spindle head form | A2-11 | ||

| Main spindle through-hole diameter | mm | Φ105 | |

| Spindle inner hole taper | 1:20 | ||

| Number of spindle stages | Manual fourth gear | ||

| Spindle speed range | r/min | 30-84/53-150/ 125-350/300-835 |

Technical Parameter

| Item | Content | Unit | CK6180 |

| Knife holder | X/Z-axis travel | mm | 420/1500 |

| Knife holder form | Electric vertical | ||

| Workstation | 4 | ||

| Tool specifications: turning/boring | mm | 32/40 | |

| Tailstock | Sleeve diameter/stroke | mm | Φ100/250 |

| The cone of the inner hole of the sleeve | MT6 | ||

| Sleeve drive form | Manual | ||

| Tail seat movement form | Manual | ||

| Spindle motor power | Kw | 11 | |

| Spindle motor torque | NM | 48 | |

| X/Z motor power | Kw | 1.5/2.3 | |

| X/Z motor torque | 10/15 | ||

| Cooling pump motor power | NM | 125 | |

| Other | Power capacity | 15 | |

| Bed saddle layout form | W | Flat bed body | |

| Guide rail form | KVA | Hard rail(>HRC55) | |

| Machine weight | kg | 5000 | |

| Machine tool dimensions: length x width x height | mm | 3400×1900×2000 | |

Recommended Products

Keep in Touch

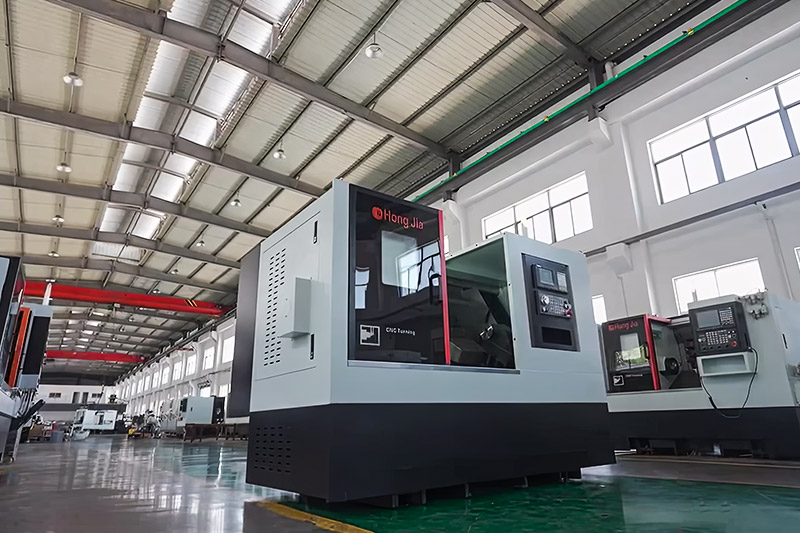

Ningbo Hongjia CNC Technology Co., Ltd.

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China CK6180 low-noise CNC horizontal lathe supplier and custom CK6180 low-noise CNC horizontal lathe company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE -

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE

Industry knowledge

CK6180 Low-Noise CNC Horizontal Lathe is Ningbo Hongjia CNC Technology Co., Ltd's active response to the high-precision machining needs of modern manufacturing. The design of this machine tool starts from the source. Its key components such as the headstock, bed, and tailstock are all finely scraped and strictly tested by hand to ensure that each machine tool undergoes a comprehensive "ship-level" inspection before leaving the factory. This process not only effectively guarantees the positioning accuracy of the Z-axis and X-axis, but also greatly improves the repeat positioning accuracy, eliminates the backlash, and ensures the long-term stability of the machine tool.

In order to further improve the durability and stability of the machine tool, CK6180 Low-Noise CNC Horizontal Lathe uses high-strength cast iron material, and innovatively adds copper and special alloy elements to it, so that the quenching depth of the bed rail reaches 3 mm. This design significantly enhances the wear resistance of the machine tool, and can maintain good machining accuracy and stability even under long-term high-load operation.

For the hot and humid climate conditions in the south, the CK6180 Low-Noise CNC Horizontal Lathe is specially designed with a centralized lubrication system. The head box adopts a circulating forced lubrication method. This innovative design not only ensures the cleanliness and good heat dissipation of the internal components of the head box, but also effectively extends the service life of bearings and gears. The intelligent lubrication management system can automatically adjust the lubrication amount and frequency according to the processing status, which not only saves maintenance costs, but also improves the overall operation efficiency of the machine tool.

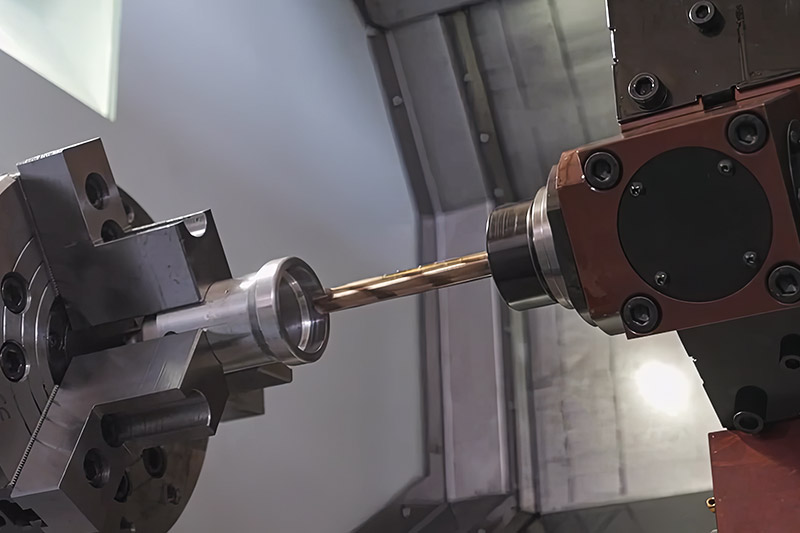

The machine tool spindle uses the renowned Harbin bearing. The spindle through-hole diameter reaches cp82mm, which can withstand a large cutting load. At the same time, the machine tool gear adopts a precision grinding process, which significantly improves the hardness and meshing accuracy of the gear, thereby greatly reducing the noise level during machine operation. With its excellent silent performance, CK6180 creates a more comfortable and efficient working environment for users, especially suitable for high-end manufacturing fields that are sensitive to noise.

In terms of transmission system, CK6180 Low-Noise CNC Horizontal Lathe adopts high-precision ball screw of Hanjiang brand. Both Z-axis and X-axis adopt ball screw design with pre-stretching structure. This configuration greatly improves the processing accuracy of cylindrical and inner hole size of workpiece, and ensures the one-time forming ability of complex parts.

In order to improve processing efficiency, CK6180 Low-Noise CNC Horizontal Lathe is equipped with a four-station non-lifting electric tool holder with a tool handle size of 25x25mm. This design not only simplifies the tool replacement process and shortens the auxiliary time, but also provides users with a wider range of tool selection space to meet diversified processing needs.

In terms of electrical control, CK6180 Low-Noise CNC Horizontal Lathe uses electrical components of Delixi brand to ensure the stability and reliability of the entire electrical system. The advanced CNC system combined with the intuitive operation interface allows even first-time operators to quickly get started, greatly reducing the difficulty of operation and improving production efficiency. At the same time, strict safety protection measures and fault warning systems provide operators with all-round safety protection.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى