Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / News / Industry News / Environmental advantages of drawout coolant tank horizontal turning center

Home / News / Industry News / Environmental advantages of drawout coolant tank horizontal turning center Environmental advantages of drawout coolant tank horizontal turning center

2025.04.21

2025.04.21

Industry News

Industry News

1. Reduce the risk of cutting fluid leakage and contamination

The traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machine tool or leak out, causing external environmental pollution. The drawout coolant tank horizontal turning center separates the storage tank from the machine tool, adopts double-layer sealed pipes and closed-loop circulation design to block the liquid leakage path. It reduces the frequency of cutting fluid replacement, reduces the problem of waste liquid treatment, and reduces chemical pollutant emissions.

2. Coolant circulation and regeneration

Independent coolant tank supports cutting fluid recovery and regeneration. Through external filtration modules and intelligent monitoring, the coolant concentration, pH value and cleanliness can be adjusted to avoid frequent replacement due to deterioration. Some systems use biodegradable cutting fluids, combined with oil-water separation technology to achieve harmless treatment of waste liquids and reduce chemical pollution to the environment. Under low load conditions, the system automatically switches to energy-saving mode to reduce power consumption.

3. Efficient chip removal and waste reduction

The intelligent chip removal system equipped with this equipment can not only quickly remove chips, but also separate ferromagnetic and non-metallic debris through the magnetic separation module. When processing composite materials, the system can simultaneously start the dust adsorption device to collect the microparticles generated by cutting into a designated container to prevent dust from spreading or mixing with coolant. Reduce the disorderly discharge of solid waste.

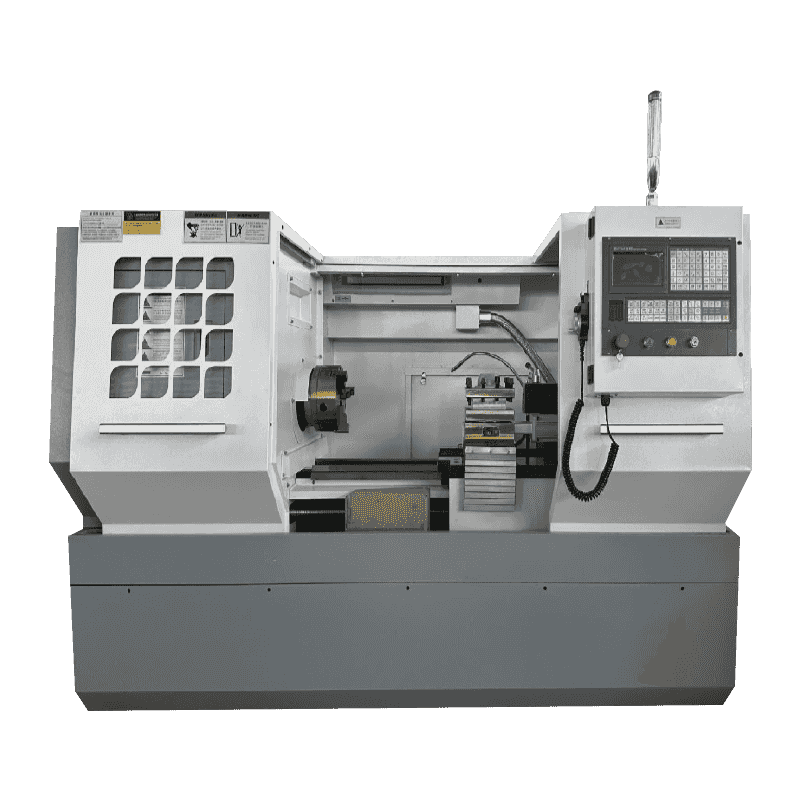

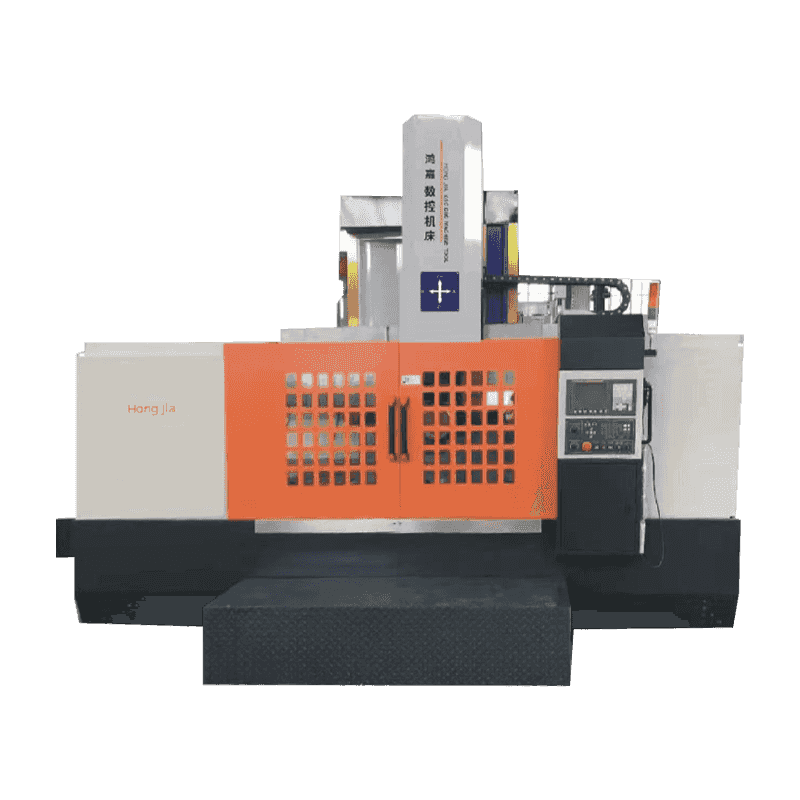

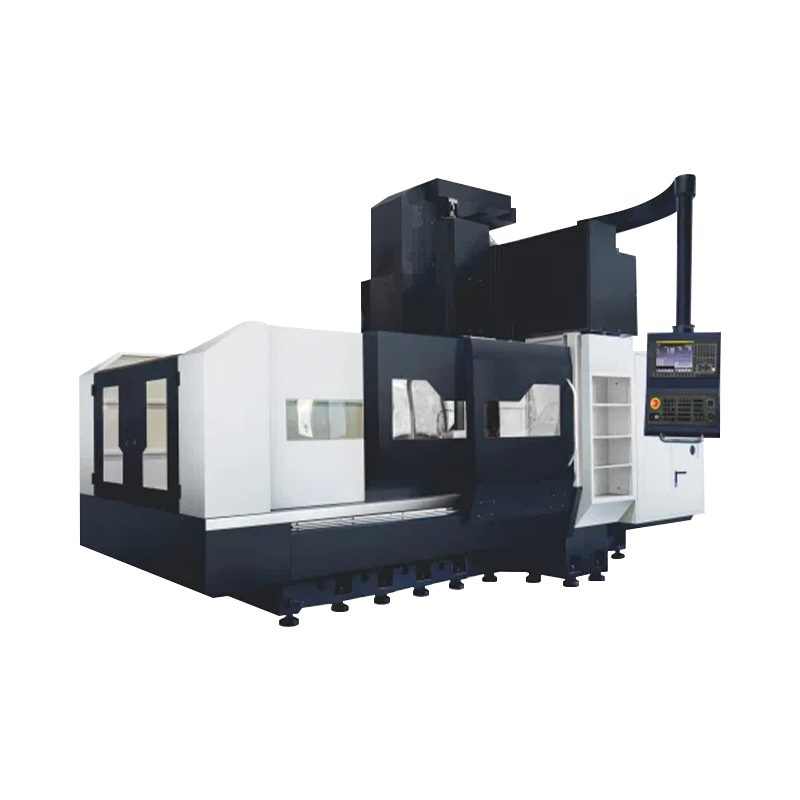

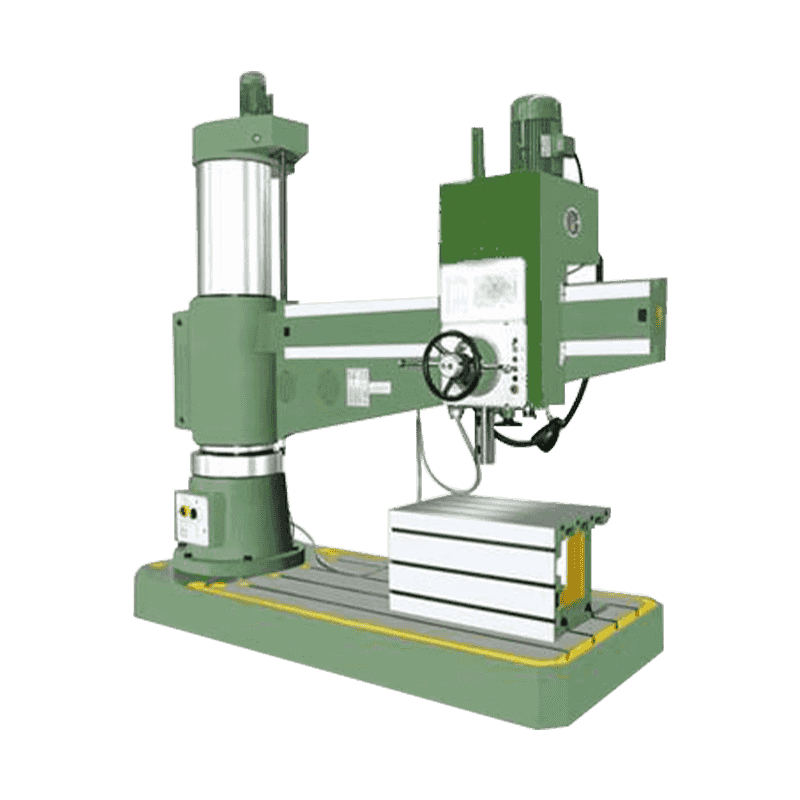

Recommended Products

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى