Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

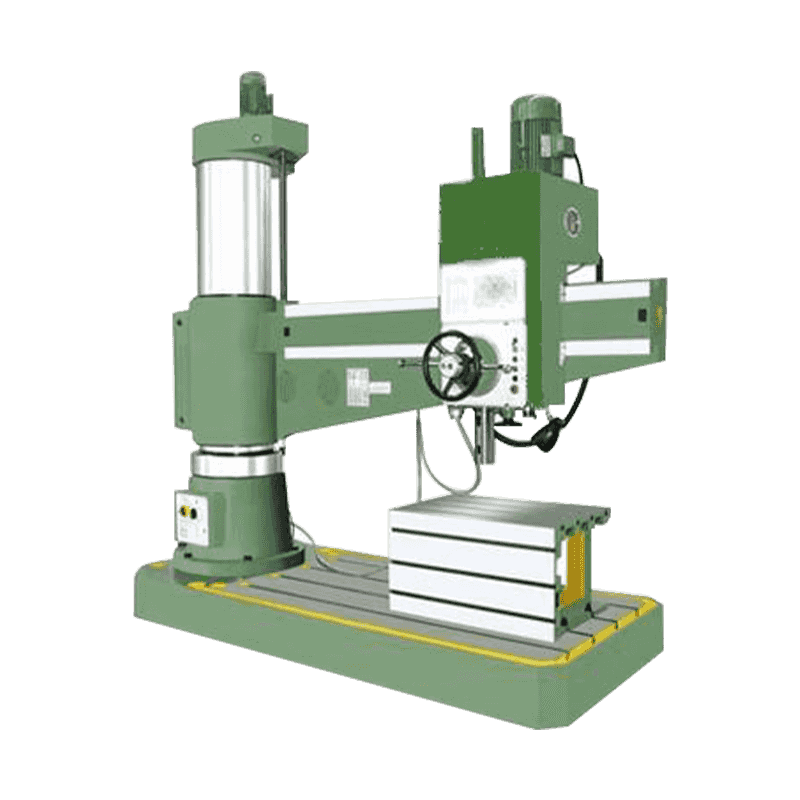

Home / Products / Ordinary turning, milling and drilling machine series / Z3050X16/1 Radial Drilling Machine

Home / Products / Ordinary turning, milling and drilling machine series / Z3050X16/1 Radial Drilling Machine Z3050X16/1 Radial Drilling Machine

Ⅰ. summarize

Z3050×16/1 radial drilling machine is a kind of multi-function drilling equipment, which is suitable for drilling, reaming, reaming, surface machining, and tapping of medium and large parts. It has the features of excellent basic components, a hydraulic preselected transmission mechanism, a hydraulic drive clamping mechanism, a high-precision guide rail and raceway, a perfect safety protection device, and so on.

Production Information

Main specifications and technical parameters

| item | specification | Single position | |

| Maximum hole diameter | 50 | mm | |

| Distance from spindle center line to column busbar | Max | 1600 | mm |

| minimum | 350 | mm | |

| Headstock horizontal travel distance | 1250 | mm | |

| Rocker arm lifting distance | 580 | mm | |

| Swing arm rotation Angle | ±180 | The degree of | |

| Spindle conical hole | Morse number five | ||

| Spindle speed range | 25-2000 | r/min | |

| Spindle speed series | 16 | level | |

| Spindle feed range | 0.04-3.2 | mm/r | |

| Spindle feed series | 16 | level | |

| Spindle travel | 315 | mm | |

| Maximum allowable torque of the spindle | 500 | N.M | |

| Maximum feed resistance allowed by spindle | 18000 | N | |

| Main motor power | 4 | kW | |

| Rocker arm lifting motor power | 1.5 | kW | |

| Hydraulic clamping motor power | 0.75 | kW | |

| Cooling pump motor power | 0.09 | kW | |

| Machine weight | 3500 | Kg | |

| Maximum machine profile size (L × W × H) | 2500×1070×2840 | mm | |

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

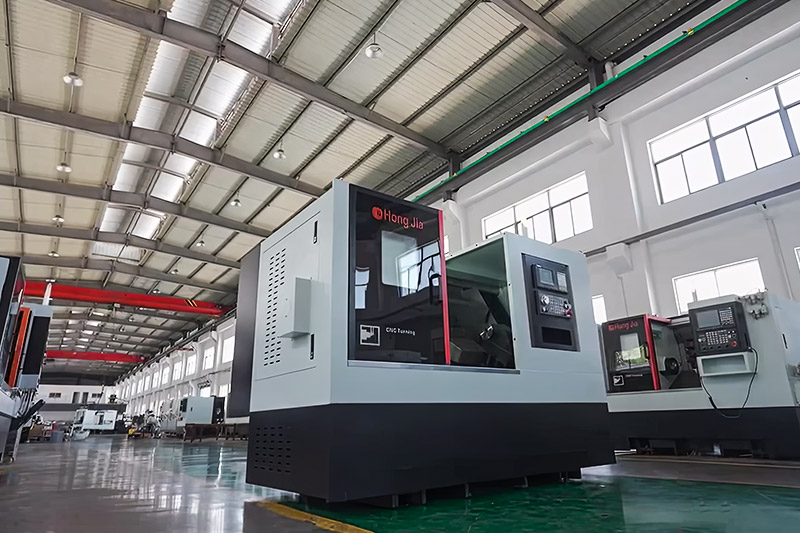

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China Z3050X16/1 Radial Drilling Machine supplier and custom Z3050X16/1 Radial Drilling Machine company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE -

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE

Industry knowledge

Radial Drilling Machine, as an important type of equipment in the field of metal cutting, plays an indispensable role in many industrial scenarios with its unique structure and wide range of applications. Among them, Ningbo Hongjia CNC Technology Co., Ltd, as a leader in the field of radial drilling machines in China, has provided many high-performance, customized radial drilling machine solutions to global customers with its profound technical accumulation and rich industry experience.

1. Diversified applications of radial drilling machines

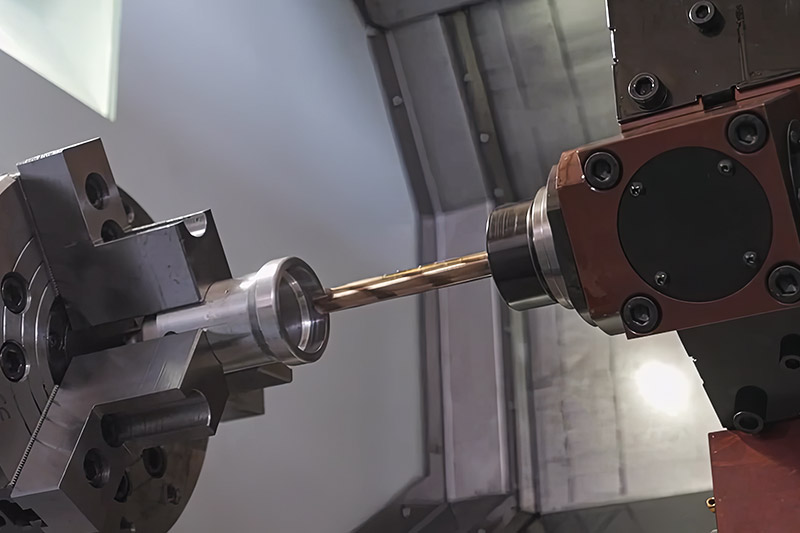

Radial Drilling Machine, with its powerful versatility, has become the preferred tool for drilling, reaming, expanding, plane processing and tapping of medium and large workpieces. Z3050X16/1 radial drilling machine, as the proud work of Ningbo Hongjia CNC Technology Co., Ltd, not only inherits all the advantages of traditional radial drilling machines, but also makes a series of innovations in design to make it more adaptable to the needs of modern manufacturing industry for high precision and high efficiency.

2. Excellent basic components and design highlights

Ningbo Hongjia CNC Technology Co., Ltd knows that a high-quality radial drilling machine cannot be separated from solid and reliable basic components. The Z3050X16/1 radial drilling machine uses a main frame made of high-strength materials to ensure the stability and durability of the machine tool under long-term and high-intensity operations. In addition, the machine tool is equipped with an advanced hydraulic pre-selection transmission mechanism. This design greatly simplifies the operation process, allowing the operator to easily switch between different speeds and feed speeds, thereby improving work efficiency.

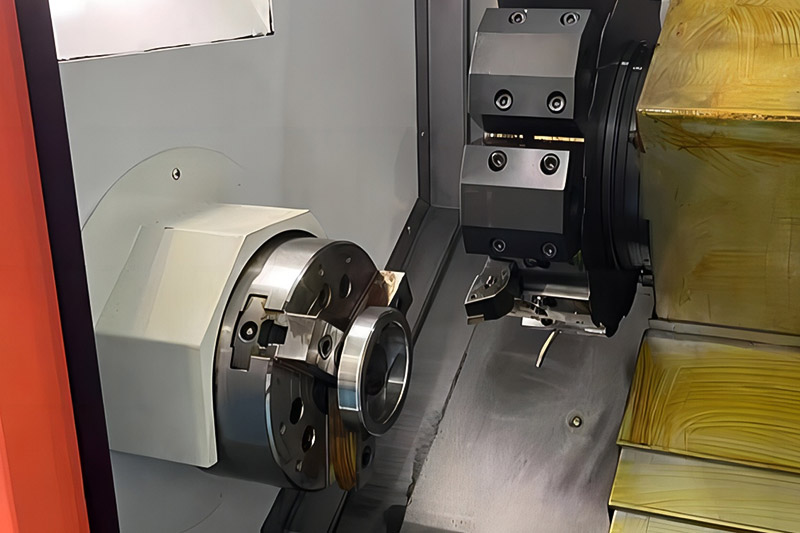

It is particularly worth mentioning that the Z3050X16/1 radial drilling machine also introduces a hydraulically driven clamping mechanism. This innovation not only improves the positioning accuracy of the workpiece, but also effectively shortens the clamping time and further shortens the processing cycle. The high-precision guide rail and runway design is the key to ensuring processing accuracy. Together, they form the basis for the stable operation of the machine tool and ensure the high-quality output of the processed parts.

3. Safe and efficient production guarantee

While pursuing efficient processing, Ningbo Hongjia CNC Technology Co., Ltd also attaches great importance to the safety and health of operators. The Z3050X16/1 radial drilling machine is equipped with complete safety protection devices, including but not limited to emergency stop buttons, protective covers, and intelligent monitoring systems. These measures effectively reduce safety risks during the operation and provide operators with a safer and more comfortable working environment.

4. Customized services to meet personalized needs

As a professional CNC metal cutting equipment supplier, Ningbo Hongjia CNC Technology Co., Ltd is well aware of the uniqueness of each customer. Therefore, in addition to providing standardized Z3050X16/1 radial drilling machines, the company also has a professional technical team that can provide a full range of customized services from design to production according to the specific needs of customers. Whether it is the size adjustment of the machine tool, the addition of special functions, or the optimization of the processing technology for specific materials, Hongjia can provide tailor-made solutions to ensure that every customer can get the radial drilling machine that best suits their production needs.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى