Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

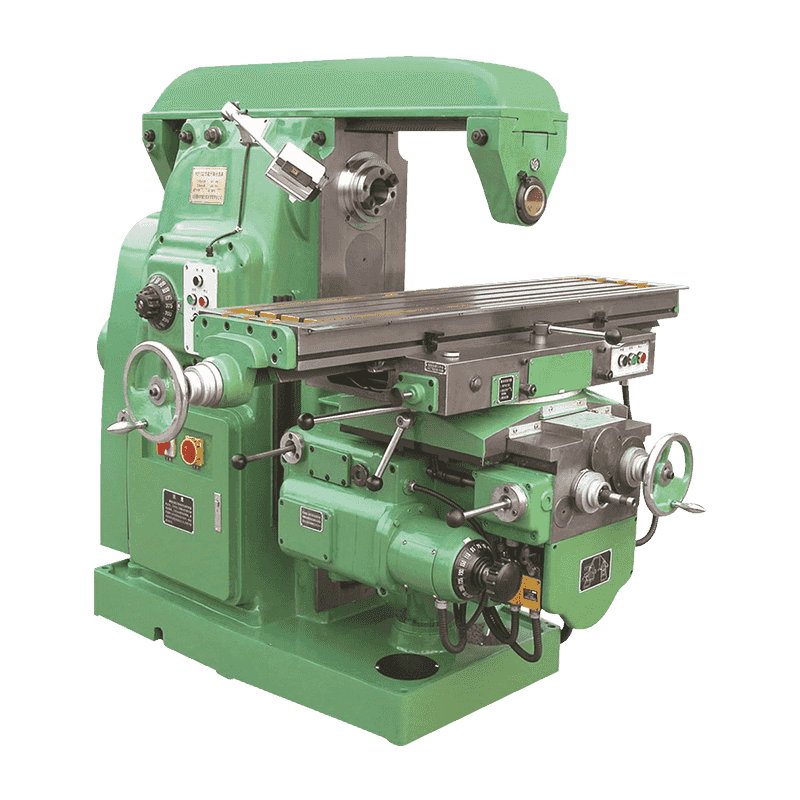

Home / Products / Ordinary turning, milling and drilling machine series / X6132 Universal Lifting Table Milling Machine

Home / Products / Ordinary turning, milling and drilling machine series / X6132 Universal Lifting Table Milling Machine X6132 Universal Lifting Table Milling Machine

Product introduction and use

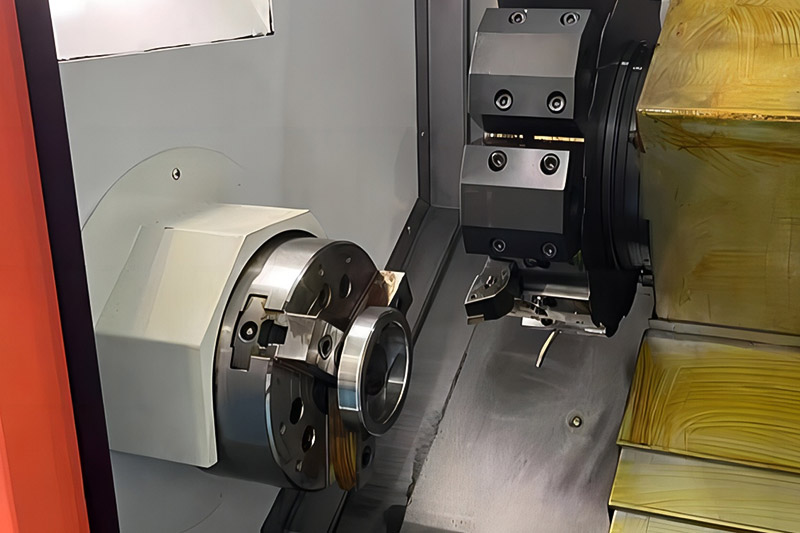

This machine tool is a kind of strong metal cutting machine tool, the machine tool has strong rigidity, a wide feed speed range, and can bear heavy load chips. The spindle cone hole can be installed directly or through the accessories of various cylindrical milling cutters, circular milling cutters, forming cutters, face milling cutters, and other tools, suitable for processing various parts of the plane, slope, groove, hole, etc., is the ideal processing equipment for machinery manufacturing, mold, instrument, instrument, automobile, motorcycle, and other industries.

Production Information

Main structural features

1, the base, fuselage, workbench, slide, lifting slide, and other main components are cast of high-strength materials, and artificial aging treatment, to ensure the long-term stability of the machine tool.

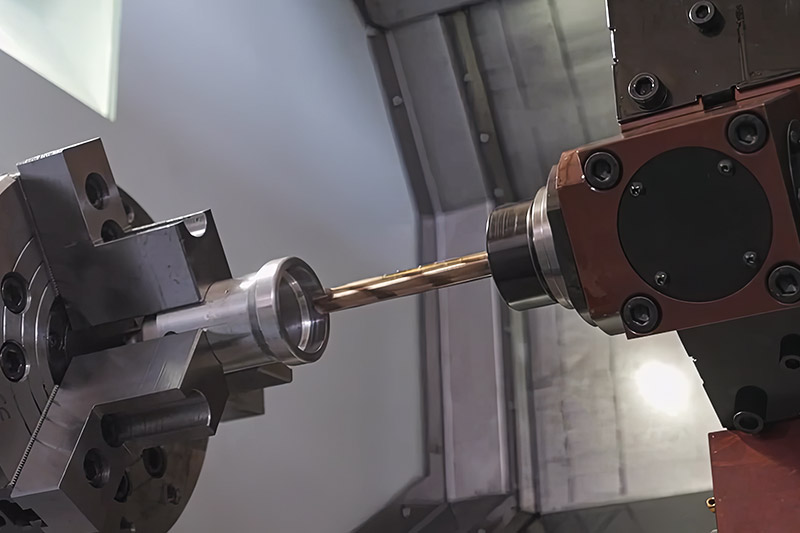

2, the main shaft bearing of the machine tool is a tapered roller bearing, the main shaft adopts three support structures, the system stiffness of the main shaft is good, the bearing capacity is strong, and the main shaft adopts energy consumption braking, the braking torque is large, and the stop is rapid and reliable.

3, the horizontal rotation Angle of the table ±45°, expands the processing range of the machine tool. The main transmission part and the feed part of the work table adopt the gear transmission structure, the speed regulation range is wide, and the speed change is convenient and fast.

4, the table X/Y/Z direction has manual feed, mobile feed, and mobile fast forward three, feed speed can meet different processing requirements; The fast feed can make the workpiece reach the processing position quickly, the processing is convenient and fast, and the non-processing time is shortened.

5, X, Y, Z three direction guide pair by ultra-audio quenching, precision grinding and scraping treatment, with forced lubrication, improve the accuracy, extend the service life of the machine.

6. The lubrication device can force the longitudinal, horizontal,l, and vertical lead screw and guide rail to lubricate, reduce the wear of the machine tool and ensure the efficient operation of the machine tool; At the same time, the cooling system changes the size of the coolant flow by adjusting the nozzle to meet different processing needs.

7, machine tool design in line with ergonomic principle, easy to operate; The operation panel is designed with figurative symbols, which is simple and intuitive.

Main technical parameters of machine tools

| Taper of the main shaft hole | 7:24 ISO50 |

| Distance from spindle center line to bed vertical guide rail | 30-350 mm |

| Distance from spindle center line to suspension beam | 155 mm |

| Spindle aperture | 29mm |

| Maximum rotation Angle of table | ±45° |

| Spindle speed range/series | 30~1500 rpm /18 level |

| Table size | 1320x320 mm |

| Table stroke longitudinal/transverse/vertical | 700(680/255(240)/320(300) mm |

| Table feed range longitudinal/transverse/vertical | Level 18 23.5-1180/23.5-1180/8-394 mm/min |

| Table fast-moving speed vertical/horizontal/vertical | 2300/2300/770 mm/min |

| Number, width, and spacing of T-shaped slots of the workbench | 3/18/70 mm |

| Main motor power | 7.5kW |

| Feed the motor power | 1.5kW |

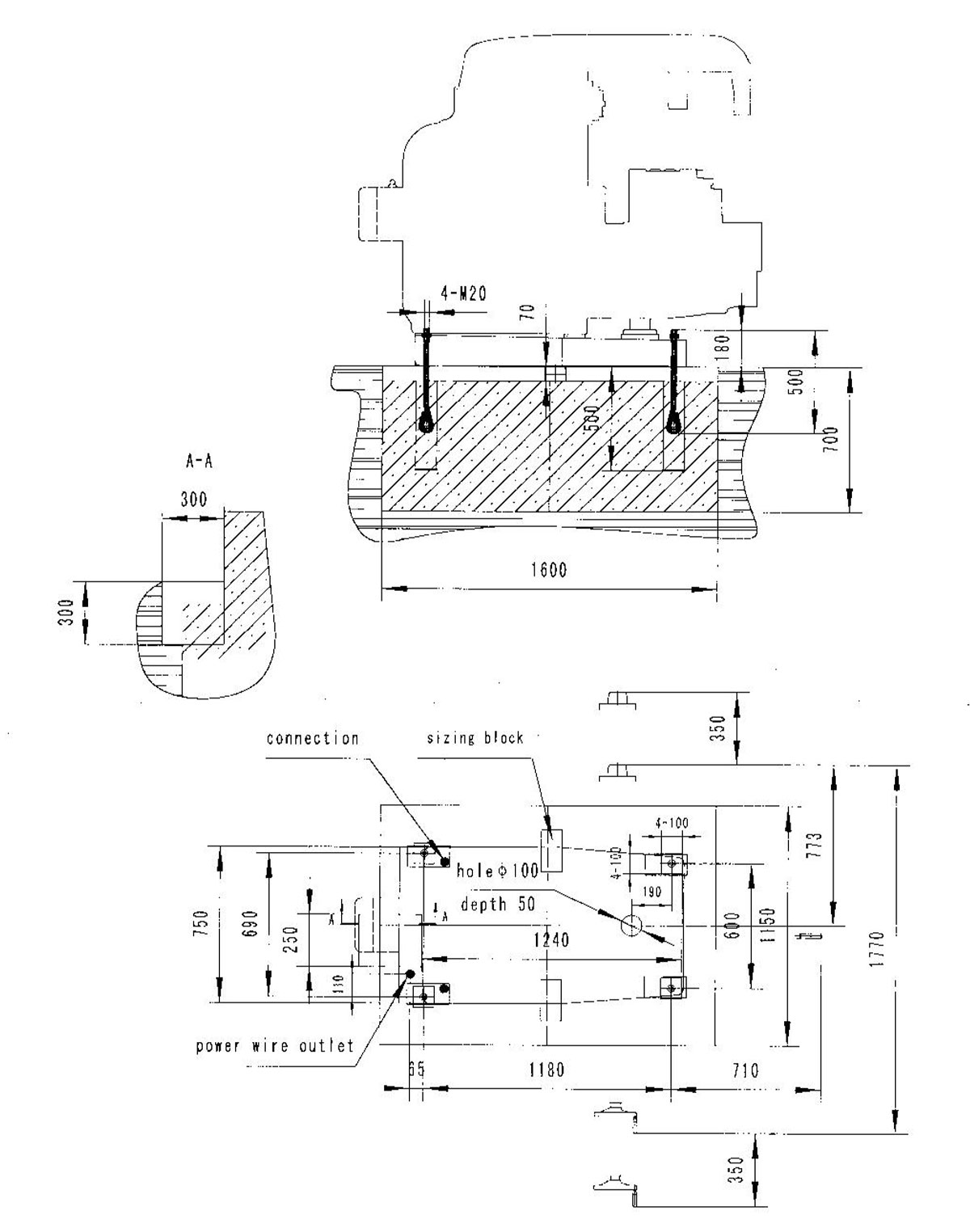

| Machine dimensions (L x W x H) | 2294x1770x1665 mm |

| Net machine weight | 2700/3000 Kg |

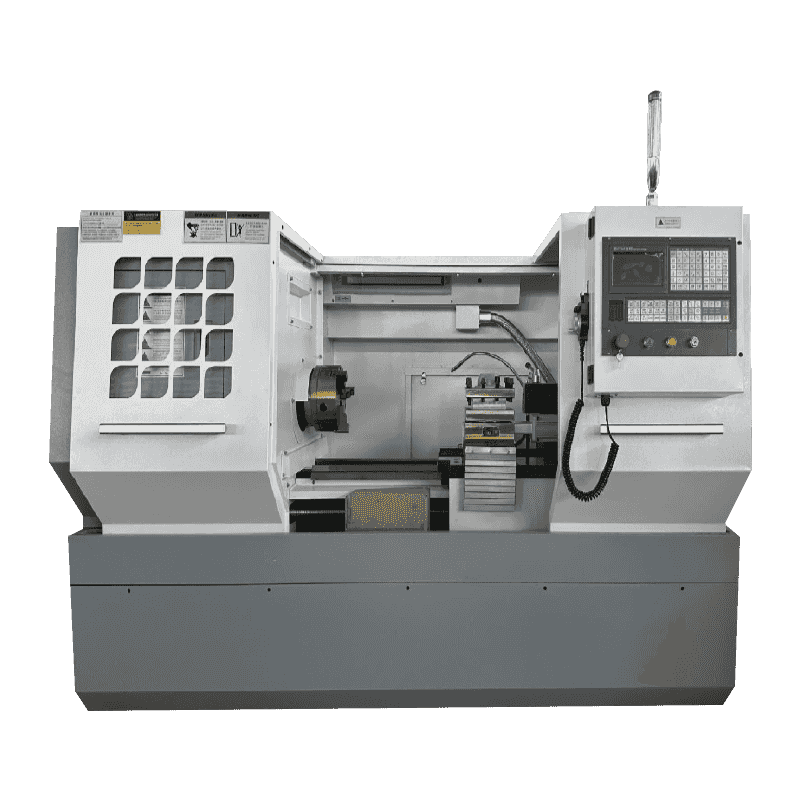

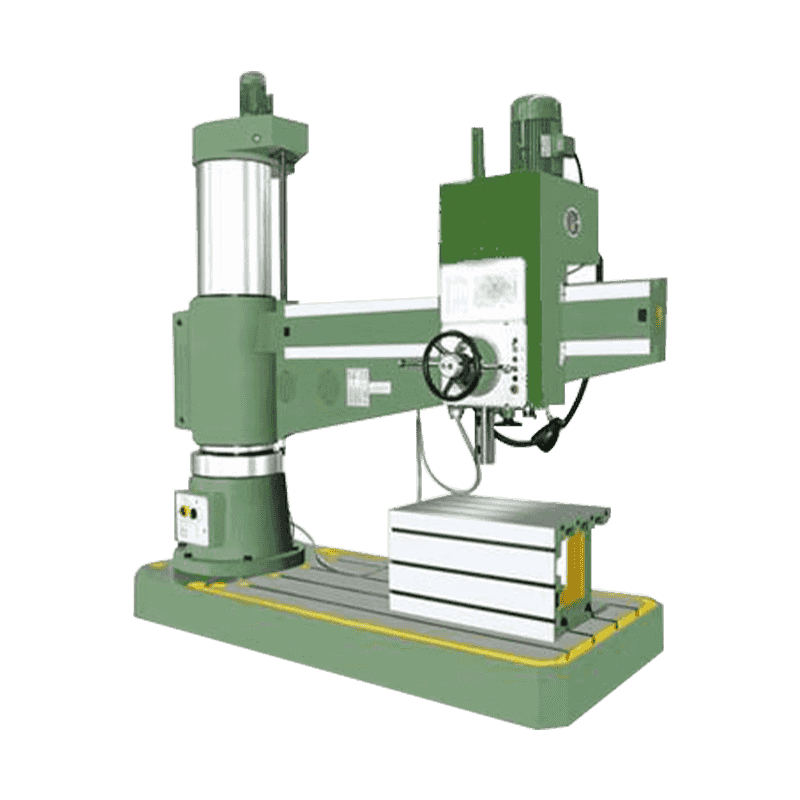

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

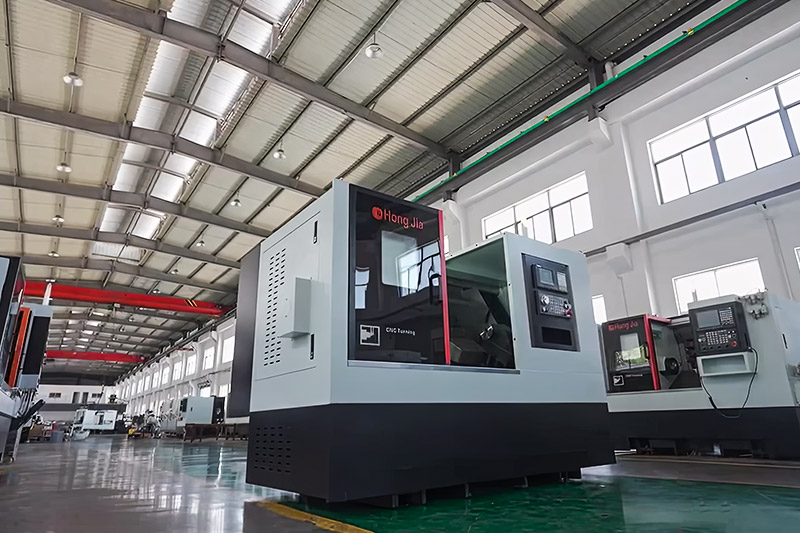

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China X6132 Universal Lifting Table Milling Machine supplier and custom X6132 Universal Lifting Table Milling Machine company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE -

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE

Industry knowledge

X6132 Universal Lifting Table Milling Machine, as a product of Hongjia CNC, has won a high reputation in many industries for its powerful metal cutting ability and wide applicability. This machine tool is not only rigid enough to withstand heavy-load cutting operations, but also equipped with a wide range of feed speeds to ensure the stability and efficiency of the processing process. Its spindle taper hole design is flexible, and various cylindrical milling cutters, circular milling cutters, forming milling cutters, face milling cutters, etc. can be installed directly or through accessories, providing unlimited possibilities for the processing of various complex parts such as planes, bevels, grooves, holes, etc. It is an ideal processing equipment for machinery manufacturing, mold manufacturing, instrumentation, automobiles, motorcycles and other industries.

Exquisite craftsmanship, casting excellent quality

Hongjia CNC knows that high quality comes from the ultimate pursuit of details. The main components of X6132 Universal Lifting Table Milling Machine, such as the base, body, workbench, slide, lifting slide, etc., are all cast with high-strength materials and artificially aged, which effectively eliminates the internal stress of the material and ensures the long-term stability and precision retention of the machine tool. The spindle adopts tapered roller bearings, combined with a three-support structure, which not only has good system rigidity and strong load-bearing capacity, but is also equipped with an energy-consuming brake device, with large braking torque and rapid and reliable shutdown, providing a solid guarantee for high-precision processing.

Flexible and changeable, broadening the processing boundaries

In order to meet the diversified processing needs, the horizontal rotation angle of the worktable of the X6132 Universal Lifting Table Milling Machine can reach ±45°. This design greatly expands the processing range of the machine tool. At the same time, the main transmission part and feed part of the worktable adopt a gear transmission structure, with a wide speed regulation range and convenient and fast speed change, making the processing process more flexible and efficient. In terms of feeding mode, the X/Y/Z directions of the machine tool have three modes: manual feeding, motorized feeding and motorized rapid feeding. The feeding speed can be flexibly adjusted according to different processing needs. The rapid feeding function allows the workpiece to quickly reach the processing position, greatly shortening the non-processing time and improving the overall processing efficiency.

Precision manufacturing, extended service life

In terms of detail processing, the X, Y, and Z guide rails of the X6132 Universal Lifting Table Milling Machine have been ultrasonically quenched, precision ground, and scraped, and the forced lubrication system has not only significantly improved the processing accuracy, but also effectively extended the service life of the machine tool. The lubrication device can force lubrication of the lead screws and guide rails in the longitudinal, transverse, and vertical directions, effectively reducing the wear of the machine tool and ensuring the efficient and stable operation of the machine tool. In addition, the cooling system flexibly adjusts the coolant flow by adjusting the nozzle to meet the cooling needs under different processing conditions, further improving the processing quality and efficiency.

Humanized design, simplified operation process

Hongjia CNC fully considered the convenience of human-machine interaction when designing the X6132 Universal Lifting Table Milling Machine. The overall design of the machine tool conforms to the principles of ergonomics, is easy to operate, and easy to use. The control panel adopts a graphical symbol design, which is intuitive and easy to understand. Even the first-time operators can quickly master it, which greatly reduces the difficulty of operation and improves work efficiency.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى