Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / Products / Horizontal CNC turning and milling series / CK6140 high-precision CNC horizontal lathe

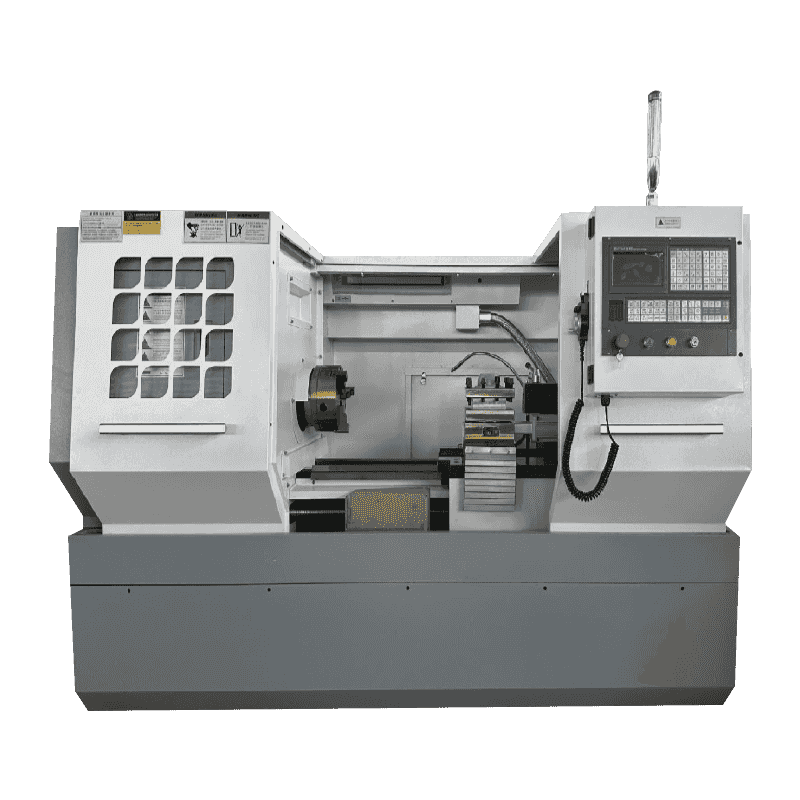

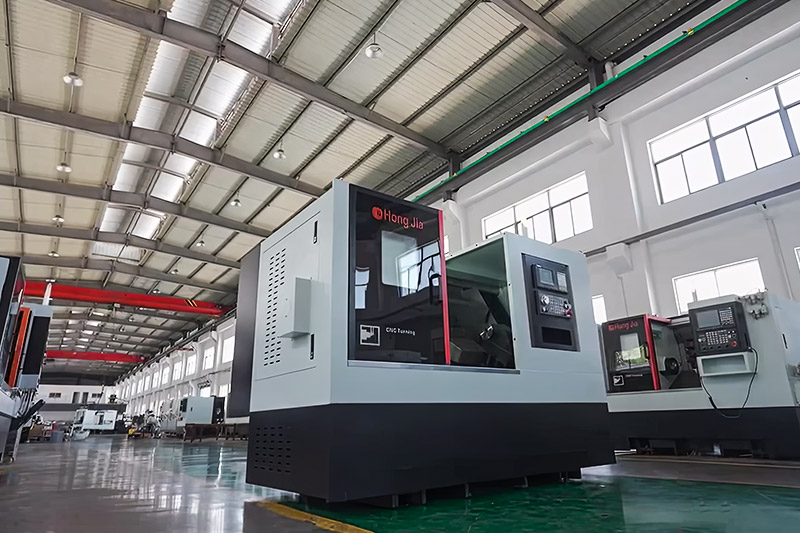

Home / Products / Horizontal CNC turning and milling series / CK6140 high-precision CNC horizontal lathe CK6140 high-precision CNC horizontal lathe

Numerical control lathe

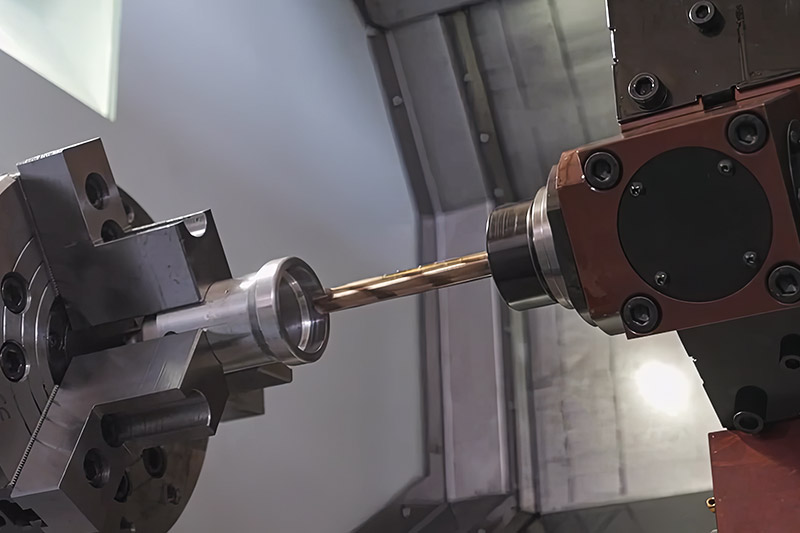

The CK6140 series CNC horizontal lathe features high precision, high power, and high rigidity. Its main components and structure are optimally designed, and it is the first choice equipment for machining shafts, discs, bushings, special-shaped surfaces, and screw-type workpieces.

Workpieces.

KND or a wide number of numerical control systems and all-digital AC servo systems, X, and Z-axis are semi-closed-loop control, ball screw sub uses C3 level precision ball screws, and electrical components are imported or domestic well-known brands, in line with CE or domestic 3C certification.

The machine tools are inspected in strict accordance with the inspection procedures before leaving the factory. Each machine tool adopts a laser interferometer to check the positioning accuracy of the X and Z axes and the repeatability of the positioning accuracy, which ensures the machine tools' stable and reliable accuracy.

Before leaving the factory, the machine tools are inspected strictly according to the inspection procedures. Each machine tool adopts a laser interferometer to test the positioning accuracy and repeatability of the X and Z axes to ensure their stability and reliability.

Production Information

Main Parts Introduction

1、Bed.

Adopting flat bed structure, resin sand molding, high quality cast iron casting, guide rail adopts medium frequency quenching and grinding and pasting molding process, which has good abrasion resistance and precision keeping.

2、Spindle box.

The spindle structure adopts the typical structure of two-point support at the front and rear ends, and the spindle has high rigidity; the bearing adopts the special bearing for a high-precision spindle of Harbin Bearing Factory, which makes the spindle have high rotary accuracy. The main drive speed range is 100~2000r/min; the main drive gears are hardened and ground, the drive, and rolling bearings are lubricated by strong oil, with good high-speed and low-temperature rise performance; the design of the spindle box case takes into full consideration of the heat dissipation measures and vibration-damping mechanism, which makes the spindle box have the features of low noise and high transmission accuracy, and the noise of the machine tool does not exceed the value stipulated by the national standard. The noise of the machine does not exceed the value stipulated by the national standard. The machine has an electrical overload protection device, a mechanical overload protection device, and an emergency stop device to control spindle rotation. The automatic speed change machine type is equipped with an external automatic speed change control box.

3. Feeding motion

The transverse (X-axis) and longitudinal (Z-axis) feeding movements are driven by servo motors to realize the rapid traverse and feeding movements with precision ball screws.

The slide guideway is affixed with an anti-creeping plastic soft belt, which can well guarantee the positioning accuracy and repeatability of the machine tool.

4. Tailstock.

The design of the tailstock of the machine gives full consideration to the rigidity, loading capacity, and user-friendliness. The tightening method is manual.

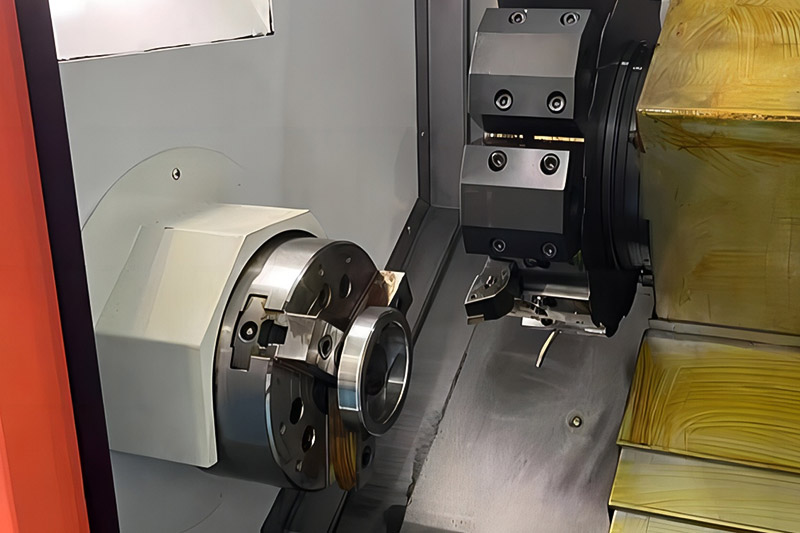

6. Chuck

The machine is equipped with an 8-inch three-jaw chuck (optional hydraulic).

7. Centralised lubrication

Adopting Japanese technology centralized lubrication system to realize the lubrication of each guide rail, ball screw, and bearing. The lubrication pump has the functions of working status display and hydraulic monitoring. And can be adjusted at any time oil injection cycle.

3、Numerical control tool holder

Vertical four-station CNC tool holder has the features of high positioning accuracy, stability and reliability, a wide range of applications, simple structure, easy maintenance, and so on.

4、Working environment of machine tool

Ambient temperature:5℃~40°℃ range and the average temperature of 24h does not exceed 35℃.

Relative humidity: 30%~95% and the principle of humidity change is that it should not cause condensation.

Altitude: below 1000m.

Atmosphere: no excessive dust, acid gas, corrosive gas and salt.

Avoid direct sunlight on the machine or heat radiation on the machine that may cause changes in the ambient temperature.

Installation position away from sources of vibration.

Installation position away from flammable and explosive materials.

Technical Parameter

| Item | Unit | CK6140 |

| Max. Turning the diameter of the bed | mm | 400 |

| Maximum turning diameter on the tool holder | mm | 210 |

| Maxi Mum workpiece length between two centers | mm | 750 |

| Spindle through hole diameter | mm | Φ52 |

| Spindle speed range | r/min | 100-2000 Gear change/Endless change |

| Spindle end type | A2-6 | |

| Spindle front taper hole | Six Mohs | |

| Spindle motor power | kw | 5.5 |

| Feed motor form | Frequency conversion | |

| Numerical control tool rest | Vertical four-station tool holder | |

| Shank size | mm | 20x20 |

| Tool holder repeated positioning accuracy | ±3.2" | |

| Feed speed range | mm/mir | X:1~6000 Z:1-10000 |

| Minimum setting unit | mm | 0.001 |

| Overall dimensions of the machine(LxWxH) | mm | 2150x1450x1650 mm |

| Gross machine weight | kg | 1900 |

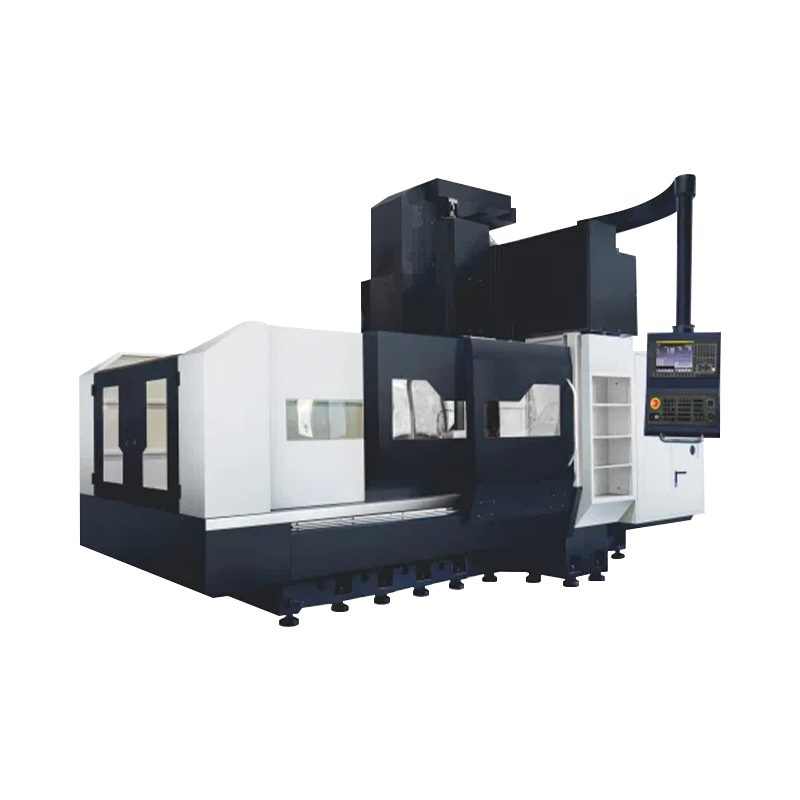

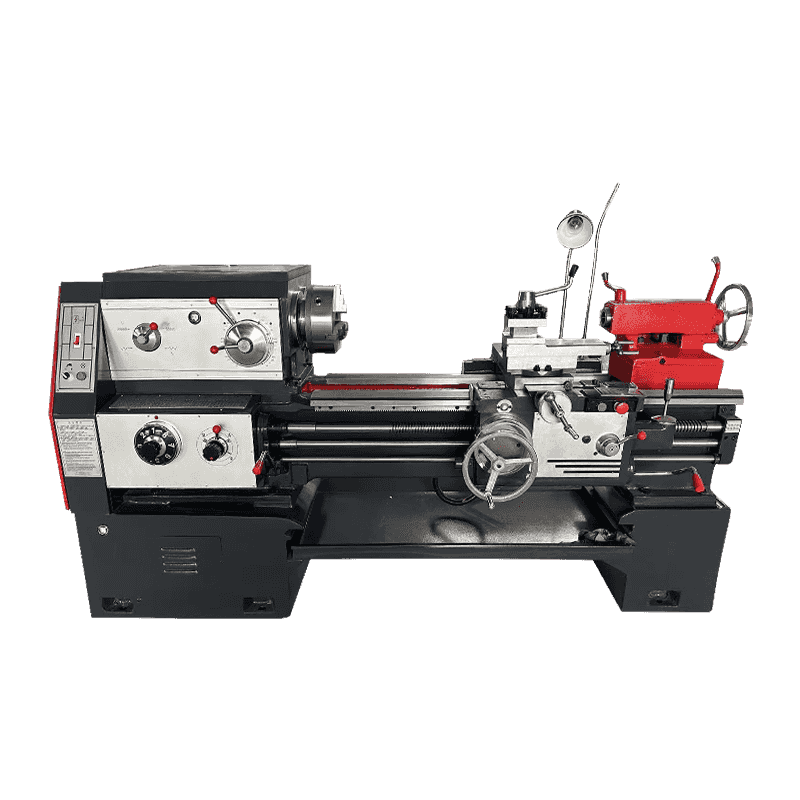

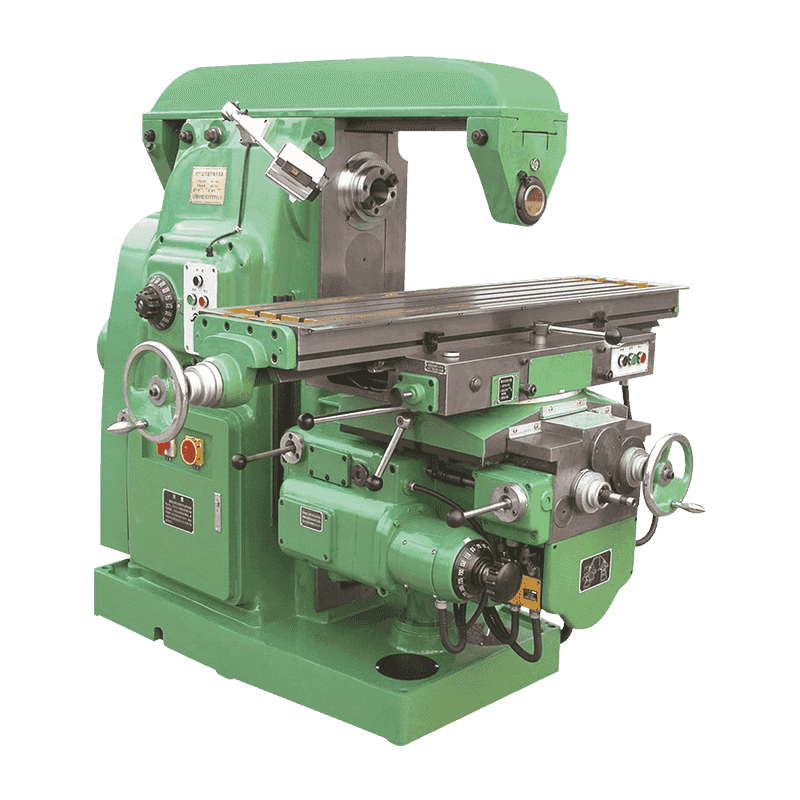

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China CK6140 high-precision CNC horizontal lathe supplier and custom CK6140 high-precision CNC horizontal lathe company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

In the wave of industrial manufacturing, low-noise CNC horizontal lathes not only continue the rigorous process of traditional mechanical processing, but also incorporate innovative materials and intelligent design, whil...

READ MORE -

As the core system of precision machining equipment, the standardization of post-use cleaning and post-maintenance of the Drawout Coolant Tank Horizontal Turning Center directly affects the machining accuracy, tool life ...

READ MORE -

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE

Industry knowledge

CK6140 High-Precision CNC Horizontal Lathe: Pioneer in Precision Manufacturing

Since its establishment, Ningbo Hongjia CNC Technology Co., Ltd. has always adhered to the corporate philosophy of "technological innovation, quality first" and is committed to the research and development and application of CNC technology. As a professional supplier and customized production factory of CK6140 High-Precision CNC Horizontal Lathe, Hongjia CNC not only has a strong R&D team that can carry out personalized design according to customer needs, but also has a complete production system and strict quality control process to ensure that each CK6140 lathe can meet or even exceed industry standards and meet the diverse needs of customers in different industries.

CK6140 High-Precision CNC Horizontal Lathe is the epitome of Hongjia CNC's technological innovation. This series of lathes stands out from many similar products with its excellent high precision, high power and high rigidity design. Its key components such as spindle, guide rail, feed system, etc. are optimized to ensure stability and precision during processing. It is particularly suitable for processing shafts, discs, sleeves, special-shaped surfaces and threaded workpieces. It is widely used in many fields such as automobiles, aerospace, and mold manufacturing, and has become an ideal choice for many manufacturers to improve production efficiency and product quality.

The configuration of CK6140 High-Precision CNC Horizontal Lathe also shows Hongjia CNC's pursuit of technological advancement. It is compatible with a variety of well-known CNC systems such as KND, as well as a fully digital AC servo system. The X-axis and Z-axis use semi-closed-loop control to ensure the precise execution of processing instructions. It is particularly worth mentioning that the C3-level precision ball screw used in the lathe not only improves the transmission efficiency, but also effectively reduces thermal deformation and ensures the long-term stability of processing accuracy. The electrical components are selected from well-known domestic and foreign brands, all of which meet CE or domestic 3C certification standards to ensure the safe and reliable operation of the equipment.

In terms of quality control, Hongjia CNC has taken extremely strict measures. Each CK6140 High-Precision CNC Horizontal Lathe must undergo a series of rigorous testing procedures before leaving the factory, among which the application of laser interferometer is particularly critical. It is used to accurately measure the positioning accuracy and repeatability of the X-axis and Z-axis to ensure that the machine tool can maintain high precision and stability in long-term use. This process not only reflects Hongjia CNC's ultimate pursuit of product quality, but also a concrete practice of its commitment to customers-each lathe is a carefully crafted work of art, worthy of trust and reliance.

In addition to its excellent product performance, Ningbo Hongjia CNC Technology Co., Ltd has also won wide acclaim in the market for its perfect service system. From pre-sales consultation, solution design, installation and commissioning to after-sales technical support, Hongjia CNC provides one-stop service to ensure that customers receive all-round support during the purchase, use and maintenance process. The company is well aware that high-quality products and services are the basis for win-win situations between enterprises and customers. Therefore, it continuously optimizes service processes, improves service quality, and is committed to building long-term and stable cooperative relationships.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى