Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / Products / Horizontal CNC turning and milling series / NC-112D Heavy Cutting Horizontal Turning Center

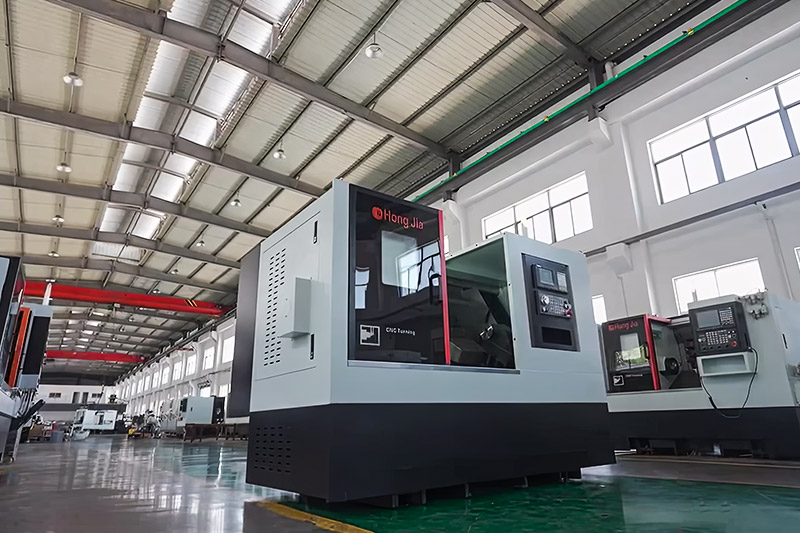

Home / Products / Horizontal CNC turning and milling series / NC-112D Heavy Cutting Horizontal Turning Center NC-112D Heavy Cutting Horizontal Turning Center

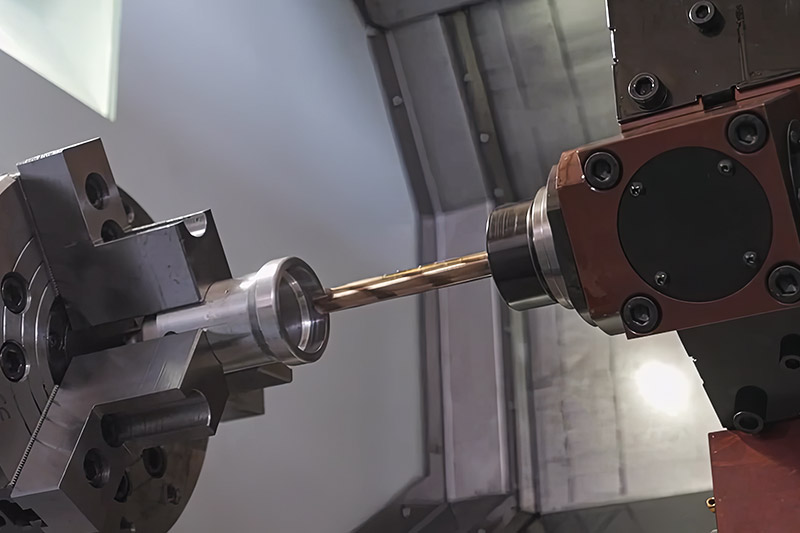

The high-torque servo spindle motor that comes standard with the heavy-duty horizontal turning center provides powerful cutting power and stability, ensuring that high-precision processing can be maintained during heavy-duty cutting operations.

The heavy-duty horizontal turning center uses high-quality linear guides and precision screws from Taiwan or Japan to ensure high precision and high rigidity of the machine tool. This not only extends the service life of the equipment, but also greatly improves the processing accuracy and surface finish.

The heavy-duty horizontal turning center is widely used in aerospace, automobile manufacturing, mold manufacturing, precision parts processing and other industries. Whether it is rough processing of large workpieces or precision processing of small parts, it can show excellent processing performance and stability.

Production Information

Processing Capability

1. Lathe, drilling, and boring can be carried out

2. High rigidity basic structure, to achieve heavy cutting

3. Excellent cutting ability and stable processing accuracy to achieve high production

4. The draw-out coolant tank is used for easy cleaning and cutting

5. Standard tank capacity: 125L

Machine tool basic configuration

1. New generation SYTEC/22TA

2. New generation drive motor

3. The new generation of high torque servo spindle motor is standard

4. Taiwan or Japan wire rail and screw

5. Separate water tank

6. Chip removal machine

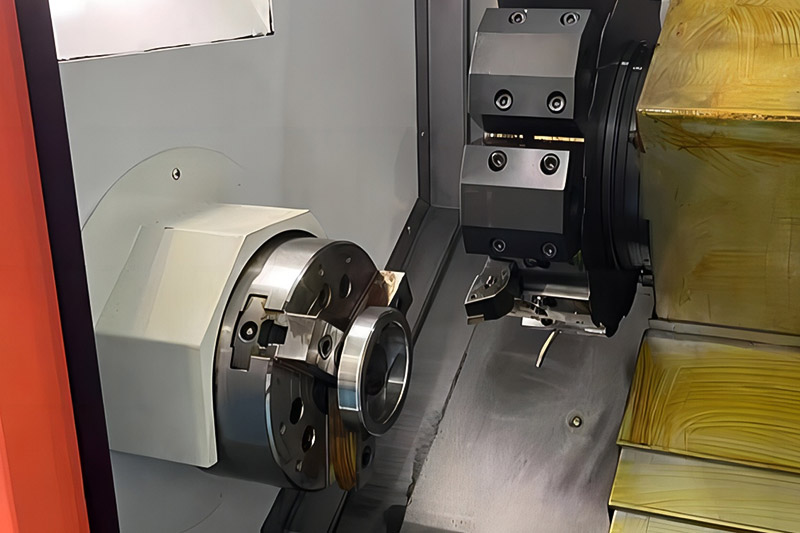

7. Oil pressure three claws

8. Standard with built-in high-speed unit precision mechanical spindle

Technical Parameter

| Item | Unit | NC-112D | |

| Max. Turning diameter of the bed | mm | Φ750 | |

| Max. machining diameter | mm | Φ600 | |

| Max. working length | mm | 970 | |

| Max. Tie rod through hole diameter | mm | Φ91 | |

| Principal axis | Spindle nose form | A2-8/11 | |

| Spindle through hole diameter | mm | Φ102 | |

| Three-jaw chuck holding capability | 12" | ||

| Pull rod action form | Hydraulic pressure | ||

| Max. spindle speed | r/min | 3000min-1 | |

| Main motor power | kW | 15/18.5 | |

| Feed | X-axis travel | mm | 350 |

| Z-axis travel | mm | 1100 | |

| X/Z axis fast-moving speed | m/min | 25 | |

| Precision | Positioning accuracy (X/Z) | mm | ±0.004 |

| Repeated positioning accuracy (X/Z) | mm | ±0.002 | |

| Power tool tower | Tool number | 12 | |

| Driving form | Servo | ||

| Height of center | mm | 125 | |

| Tool change time (T-T) | Seconds | 0.2 | |

| Boring tool holder specifications | mm | 50 | |

| Square tool holder specifications | mm | 25 | |

| Power head speed | r.p/min | 4000 | |

| Power head motor power | KW | 3.6 | |

| Power head torque | N.m | 15 | |

| Power head type | BMT | 65 | |

| Tailstock | Taper of tailstock sleeve | MT-5 | |

| Center sleeve diameter | mm | Φ80 | |

| Top sleeve maximum travel | mm | 100 | |

| Safety shield | Completely closed | ||

| Numerical control system | New generation 22TA/FANUC0I-TF | ||

| Machine weight | Kg | 5800 | |

| Overall dimensions of the machine (LxWxH) | mm | 3480X2200X1950 | |

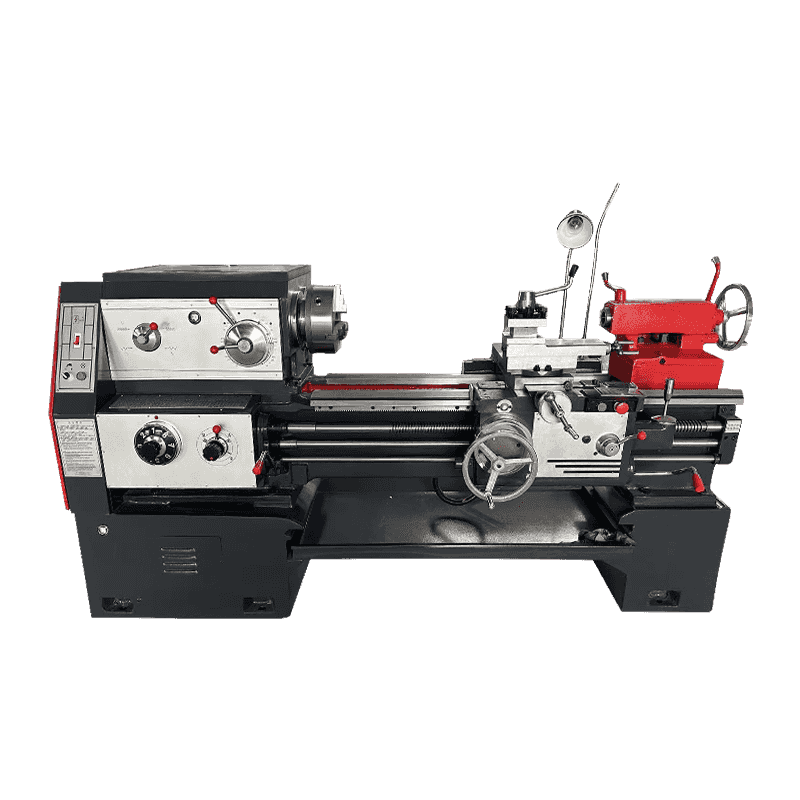

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China NC-112D Heavy Cutting Horizontal Turning Center supplier and custom NC-112D Heavy Cutting Horizontal Turning Center company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE -

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE

Industry knowledge

The NC-112D Heavy Cutting Horizontal Turning Center carefully built by Ningbo Hongjia CNC Technology Co., Ltd is designed for heavy-duty cutting tasks of large workpieces. One of its core highlights is the standard high-torque servo spindle motor, which not only provides powerful cutting power, but also ensures that high-precision processing can be maintained even when subjected to heavy-load cutting operations. This design not only meets the urgent needs of the industrial field for efficient production, but also demonstrates Hongjia CNC's profound foundation in technological innovation.

In order to further improve the processing accuracy and rigidity of the equipment, the NC-112D Heavy Cutting Horizontal Turning Center uses high-quality linear guides and precision lead screws from Taiwan or Japan. The introduction of these components not only greatly improves the overall accuracy and rigidity of the machine tool, effectively extends the service life of the equipment, but also significantly improves the surface finish and dimensional accuracy of the processed parts. This extreme pursuit of details is Ningbo Hongjia CNC Technology Co., Ltd's profound interpretation of the "craftsman spirit", and it is also an important reason why its products have won wide acclaim in the market.

The wide application of NC-112D Heavy Cutting Horizontal Turning Center is another highlight. Whether it is rough machining of large components in the aerospace field or precision parts machining in automobile manufacturing and mold manufacturing, the equipment can show excellent machining performance and stability. Its powerful machining capability is not only reflected in the fast and efficient cutting of large workpieces, but also in the precision machining of small-sized parts, which truly realizes "one machine for multiple uses" and greatly improves production efficiency and flexibility.

In terms of functional design, NC-112D Heavy Cutting Horizontal Turning Center also shows extraordinary flexibility and convenience. The equipment not only supports a variety of machining methods such as lathes, drilling, boring, etc., but is also equipped with a new generation of SYTEC/22TA control system and drive motor, making the operation more intelligent and humanized. In addition, the standard pull-out coolant tank design not only facilitates daily cleaning and maintenance, but also ensures sufficient coolant supply during the cutting process, effectively prolongs the tool life and improves the machining quality.

In addition to the above core advantages, the NC-112D Heavy Cutting Horizontal Turning Center is also designed with great care in details. For example, the independent water tank design not only ensures the recycling of cutting fluid, but also effectively avoids the pollution of cutting fluid; the efficient chip removal mechanism ensures the rapid removal of chips during processing, avoiding processing errors caused by chip accumulation; and the application of hydraulic three-jaw chuck further improves the stability and accuracy of workpiece clamping, providing a strong guarantee for high-precision processing.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى