Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / News / Industry News / Drawout Coolant Tank Horizontal Turning Center: How to reconstruct an efficient processing ecosystem with a separate design?

Home / News / Industry News / Drawout Coolant Tank Horizontal Turning Center: How to reconstruct an efficient processing ecosystem with a separate design? Drawout Coolant Tank Horizontal Turning Center: How to reconstruct an efficient processing ecosystem with a separate design?

2025.04.14

2025.04.14

Industry News

Industry News

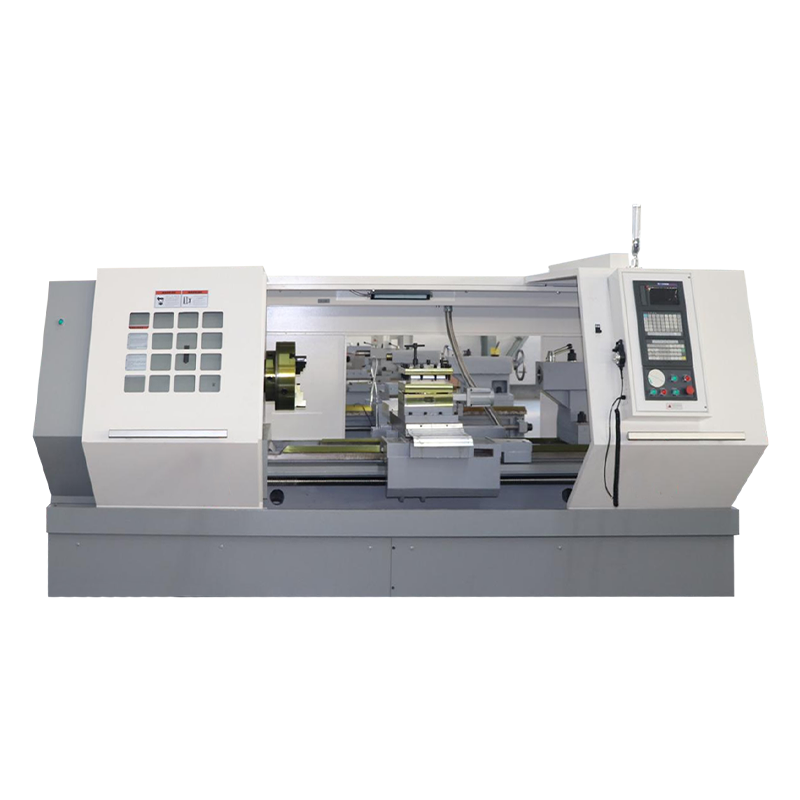

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting fluid reservoir from the machine tool body, avoiding the risk of cutting fluid corrosion on the precision parts of the machine tool and reducing the machine tool failure rate caused by cutting fluid leakage. The independent water tank not only enhances the overall protection performance of the machine tool, but also keeps the machine tool dry and clean, extending the service life of the equipment.

The cutting fluid storage system of the traditional turning center is often installed together with the machine tool body, and is exposed to metal debris and oil mist erosion for a long time, which can easily cause precision attenuation of core components such as precision guide rails and lead screws. The drawout coolant tank physically separates the cutting fluid storage unit from the machine tool body. This design not only reduces the risk of cutting fluid leakage, but also achieves stable pressure of the cutting fluid through a sealed pipeline delivery system.

The efficient chip removal system is another core advantage of the equipment. Traditional chip removal devices often make it difficult to clean the machine due to chip entanglement and accumulation, but the intelligent chip conveyor equipped in the center can dynamically adjust chip removal through multi-modal recognition technology, avoiding machine tool failure and reduced processing accuracy caused by chip accumulation.

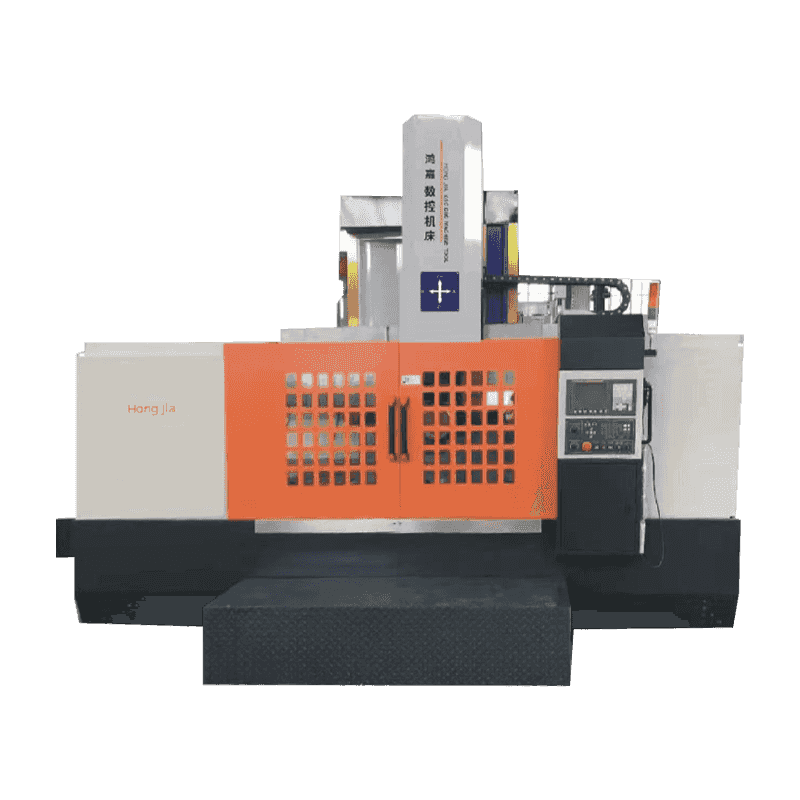

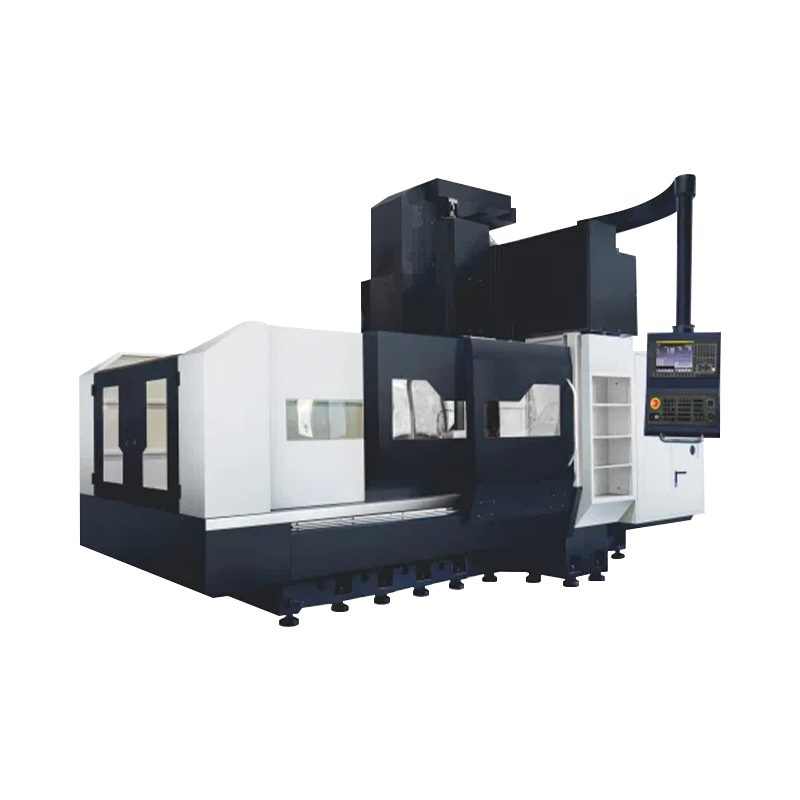

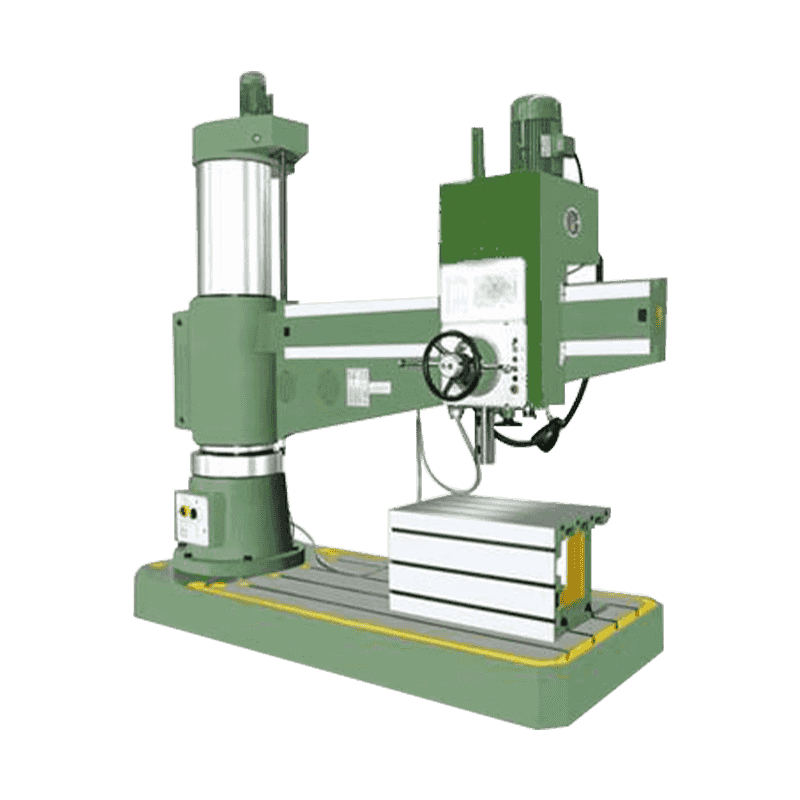

Recommended Products

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى