Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

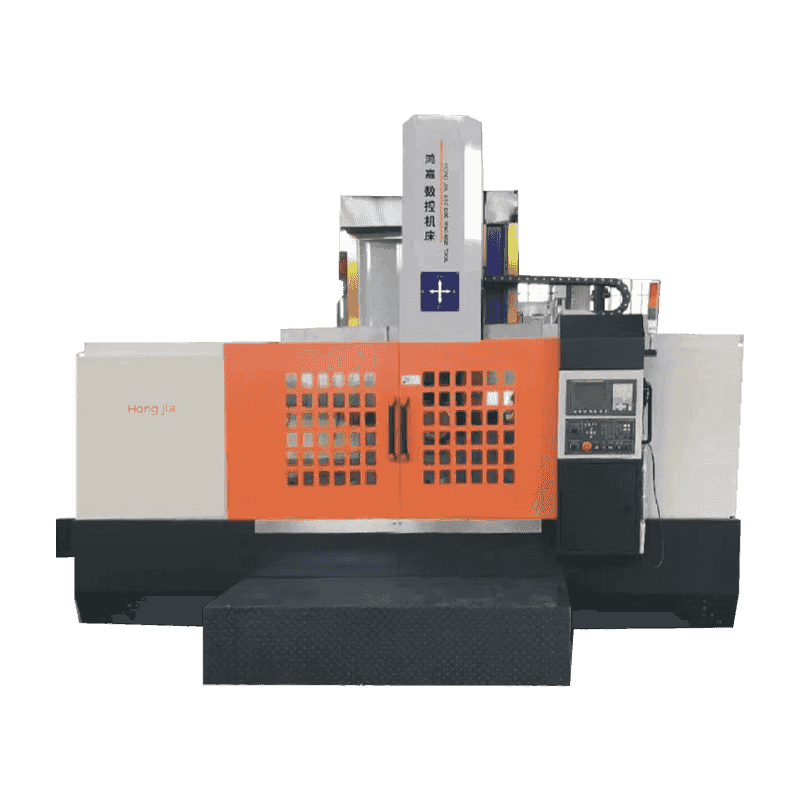

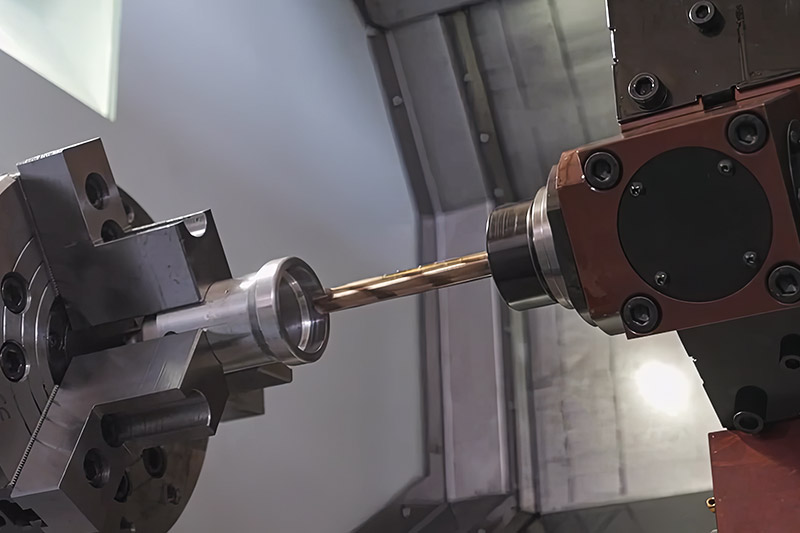

CK-5112B CNC single-column vertical lathe

Numerical control lathe

CK51 series CNC single-column vertical lathe is a high-tech mechatronic product that our company absorbs the contemporary advanced design and manufacturing technology, adopts CAD optimization design method, implements enterprise precision standard, configures domestic and foreign advanced functional components, and realizes strong cutting force in structural performance, super-heavy load on the table, high dynamic and static rigidity of the machine tool, safety and reliability of all movements, long service life and high processing efficiency. The machine is a high-tech electromechanical integrated product.

Production Information

Machine configuration

1. Siemens 808D CNC system;

2. 320 four-station electric cutting table;

3. Four-speed continuously variable transmission, main motor 22KW servo motor;

4. Semi-enclosed protection, crossbeam protection, chip removal, water cooling;

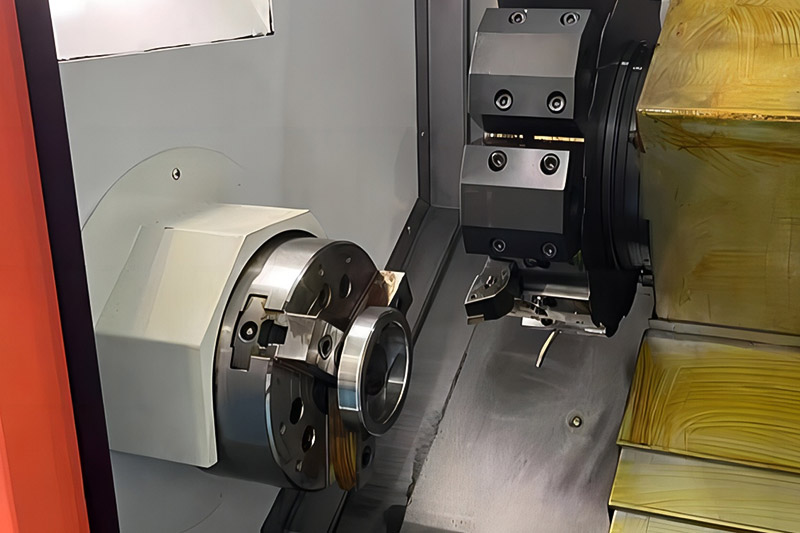

5. Equipped with a 1000mm diameter three-jaw self-centering hydraulic chuck;

6. The machine tool has no threading function and does not come with a spindle encoder;

7. The workbench base is supported by rolling guide rails.

Machine tool usage

This machine tool is suitable for high-speed steel cutting tools, hard alloy cutting tools, and various high-performance cutting tools to process black metal, non-ferrous metal, and some non-metallic material workpieces. It can complete rough and precision turning of inner and outer cylindrical surfaces, inner and outer conical surfaces, flat surfaces, rotary surfaces, and grooves on the machine tool.

Technical Parameter

| Item | Unit | CK5112B |

| Cutting tool post the biggest diameter | mm | 1250 |

| Hydraulic chuck diameter | mm | 1000 |

| Maximum height of the workpiece | mm | 1000 |

| Maximum weight of workpiece | t | 3.5 |

| Workbench speed range | r/min | 1-200 |

| Bench speed level | Four-speed stepless | |

| Maximum torque of workbench | Kn/m | 25 |

| Number of feed stages for the tool holder | level | Stepless |

| Maximum cutting force of the upright tool holder | KN | 20 |

| Horizontal stroke | mm | 700 |

| Vertical stroke | mm | 650 |

| Crossbeam travel | mm | 650 |

| Range of feed rate for tool holder | mm/min | 0.1-500 |

| Rapid movement speed of the tool holder | mm/min | 2500 |

| Beam lifting speed | mm/min | 440 |

| Knife bar cross-sectional dimensions (length x width) | mm | 30×40 |

| Main motor power | kW | 22 |

| System configuration | Siemens 808D | |

| CNC coordinate axis | X. Z-axis linkage | |

| Machine weight (approximately) | t | 13 |

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

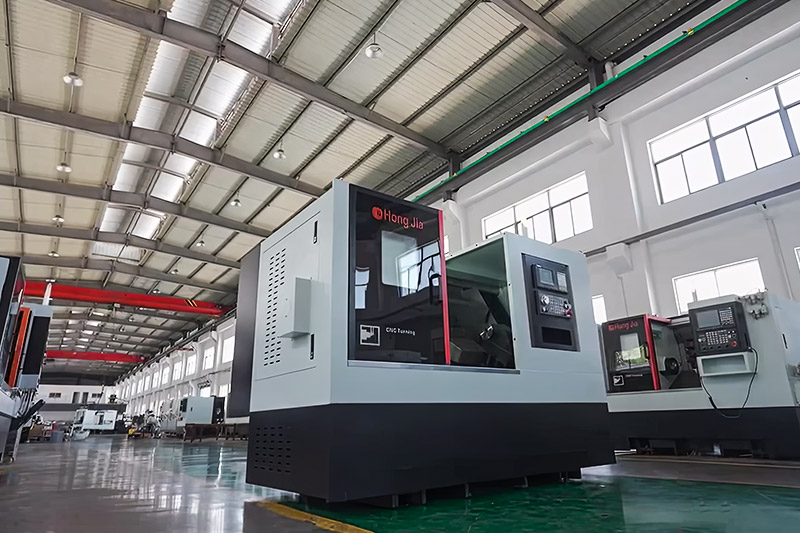

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China CK-5112B CNC single-column vertical lathe supplier and custom CK-5112B CNC single-column vertical lathe company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

As the core system of precision machining equipment, the standardization of post-use cleaning and post-maintenance of the Drawout Coolant Tank Horizontal Turning Center directly affects the machining accuracy, tool life ...

READ MORE -

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE -

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE

Industry knowledge

CK-5112B CNC Single-Column Vertical Lathe is a high-tech mechatronics product born from Ningbo Hongjia CNC's active response to market demand and integration of contemporary advanced design and manufacturing technologies. In the design process of this series of machine tools, Hongjia CNC adopted the CAD optimization design method to ensure that every detail is carefully calculated and optimized, which not only improves the overall performance of the machine tool, but also demonstrates its profound heritage in the field of precision manufacturing. By implementing corporate precision standards and configuring advanced functional components at home and abroad, CK-5112B CNC Single-Column Vertical Lathe achieves strong cutting force in structural performance, and the workbench can withstand overweight loads, while maintaining the high dynamic and static stiffness of the machine tool, ensuring the safety and reliability of all movements.

The core configuration of CK-5112B CNC Single-Column Vertical Lathe highlights its identity as a high-end CNC equipment. It is equipped with Siemens 808D CNC system. This internationally renowned brand is known for its stability, reliability and easy operation, and provides users with an intuitive and easy-to-use programming and monitoring interface. The machine tool is equipped with a 320mm four-station electric turntable, which greatly expands the processing range and improves processing flexibility. The four-speed continuously variable transmission system is equipped with a 22KW servo main motor to ensure that the appropriate cutting speed and torque can be provided under different working conditions to meet diverse processing needs.

In terms of safety performance, CK-5112B CNC Single-Column Vertical Lathe adopts a semi-enclosed protection design, which effectively isolates the splashes during the processing and protects the safety of the operator. At the same time, the crossbeam protection, debris removal and water cooling system further improve the cleanliness of the processing environment and the operating efficiency of the machine tool. It is particularly worth mentioning that the machine tool is equipped with a three-jaw self-centering hydraulic chuck with a diameter of 1000mm as standard. This configuration greatly enhances the clamping stability and processing accuracy of the workpiece.

Although the CK-5112B CNC Single-Column Vertical Lathe does not have a thread processing function and is not equipped with a spindle encoder, this does not affect its wide application in a variety of material processing fields. The machine tool is suitable for high-speed steel tools, carbide tools and various high-performance tools, and can efficiently process ferrous metals, non-ferrous metals and some non-metallic workpieces. Whether it is an inner and outer cylindrical surface, an inner and outer conical surface, a plane, a rotary surface or a groove, the CK-5112B CNC Single-Column Vertical Lathe can easily complete roughing and finishing, showing excellent processing capabilities and flexibility.

The worktable base is supported by a rolling guide rail, which is another highlight of the CK-5112B CNC Single-Column Vertical Lathe in structural design. The rolling guide rail not only reduces motion friction, improves positioning accuracy and repeat positioning accuracy, but also ensures the stability and durability of the machine tool under long-term operation. This design enables the CK-5112B CNC Single-Column Vertical Lathe to maintain extremely high machining accuracy and surface quality when machining complex-shaped workpieces, meeting the needs of industries such as aerospace, automobile manufacturing, and mold processing for high-precision parts.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى