Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / Products / Horizontal CNC turning and milling series / NC110 Precision Mechanical Spindle Horizontal Turning Center

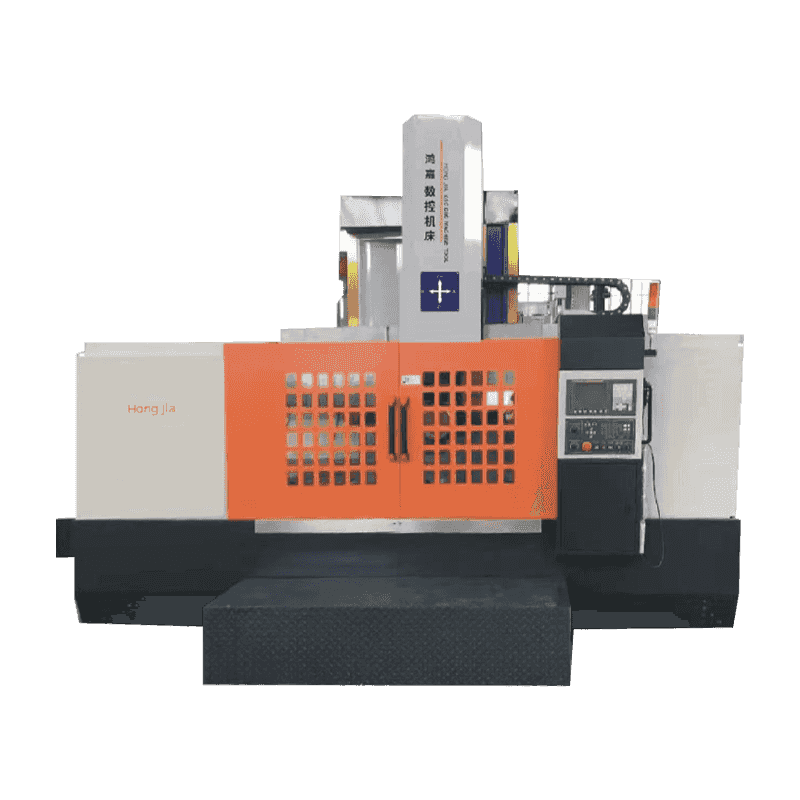

Home / Products / Horizontal CNC turning and milling series / NC110 Precision Mechanical Spindle Horizontal Turning Center NC110 Precision Mechanical Spindle Horizontal Turning Center

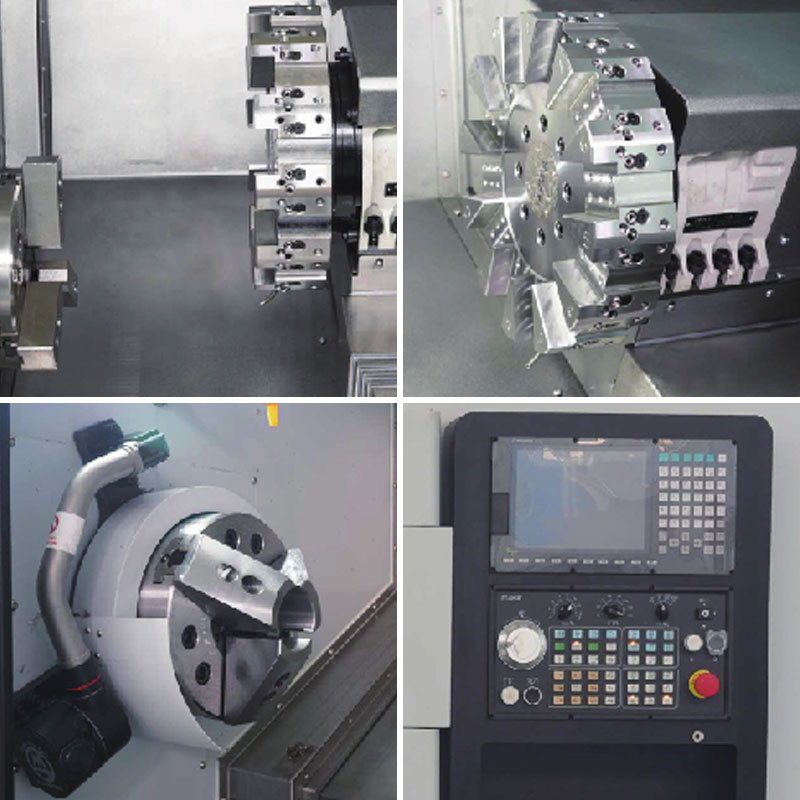

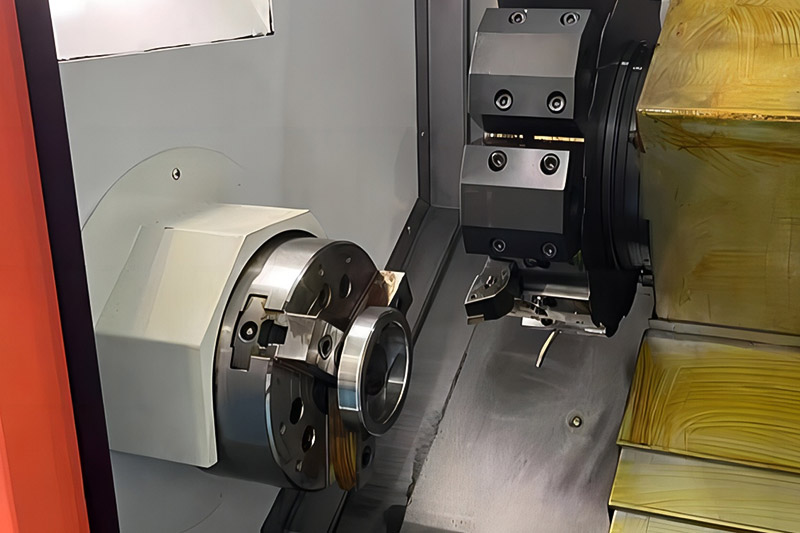

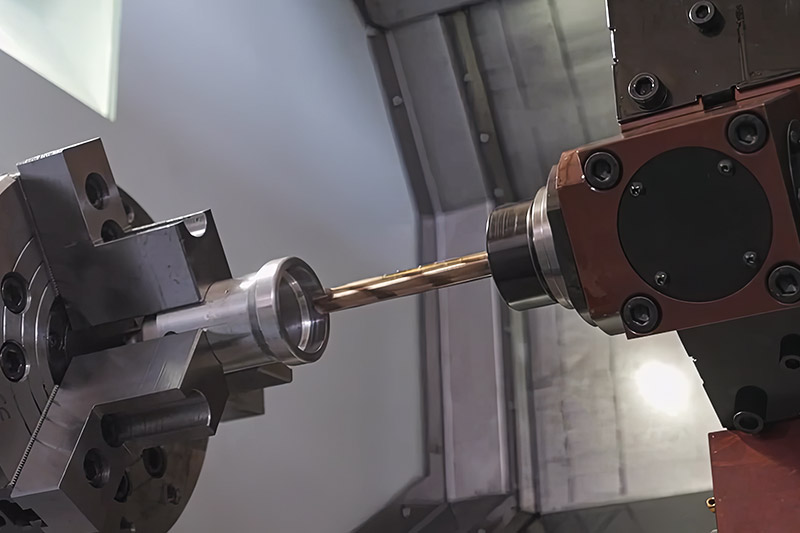

The hydraulic three-jaw chuck is an important part of this precision mechanical spindle horizontal turning center. Its design fully considers the stability and safety of workpiece clamping during processing. The three-jaw chuck adopts hydraulic drive mode, and provides stable clamping force through the hydraulic system to ensure that the workpiece will not be displaced due to vibration or external force during processing, thereby ensuring processing accuracy and safety.

The standard precision mechanical spindle with built-in high-speed unit is made of advanced technology and high-quality materials, with high-speed and high-precision processing capabilities. The built-in high-speed unit enables the spindle to easily achieve high-speed rotation, thereby meeting the needs of high-speed cutting and drilling operations. Whether it is precision contour processing or high-speed drilling operations, the spindle can provide stable and accurate processing results. At the same time, high-speed rotation can also improve cutting efficiency, shorten processing cycle, and reduce production costs.

Production Information

Processing Capacity

1. Lathe, drilling, and boring can be carried out

2. High rigidity basic structure, to achieve heavy cutting

3. Excellent cutting ability and stable processing accuracy to achieve high production

4. The draw-out coolant tank is used for easy cleaning and cutting

5. Standard tank capacity: 125L

Machine tool basic configuration

1. New generation SYTEC/22TA

2. New generation drive motor

3. The new generation of high torque servo spindle motor is standard

4. Taiwan or Japan wire rail and screw

5. Separate water tank

6. Chip removal machine

7. Oil pressure three claws

8. Standard with built-in high-speed unit precision mechanical spindle

Technical Parameter

| Item | Unit | NC-110 | |

| Max. Turning the diameter of the bed | mm | Φ750 | |

| Max. machining diameter | mm | Φ600 | |

| Max. working length | mm | 700 | |

| Max. Tie rod through hole diameter | mm | Φ75 | |

| Principal axis | Spindle nose form | A2-8/11 | |

| Spindle through hole diameter | mm | Φ86 | |

| The taper of the spindle inner hole | MT-6 | ||

| Three-jaw chuck holding capability | 10" | ||

| Pull rod action form | Hydraulic pressure | ||

| Max. spindle speed | r/min | 2500min-1 | |

| Main motor power | kW | 15/18.5 | |

| Feed | X-axis travel | mm | 350 |

| Z-axis travel | mm | 750 | |

| X/Z axis fast-moving speed | m/min | 25 | |

| Precision | Positioning accuracy (X/Z) | mm | ±0.005 |

| Repeated positioning accuracy (X/Z) | mm | ±0.003 | |

| Dota | Tool number | 12 | |

| Driving form | servo | ||

| Height of center | mm | 100 | |

| Tool change time (T-T) | s | 0.2 | |

| Boring tool holder specifications | mm | 50 | |

| Square tool holder specifications | mm | 25 | |

| Tailstock | Taper of tailstock sleeve | MT-5 | |

| Center sleeve diameter | mm | Φ80 | |

| Top sleeve maximum travel | mm | 100 | |

| Safety shield | Completely closed | ||

| Numerical control system | new generation 22TA/FANUC Oi-TF | ||

| Machine weight | Kg | 5200 | |

| Overall dimensions of the machine (LxWxH) | mm | 2980×2200×1950 | |

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

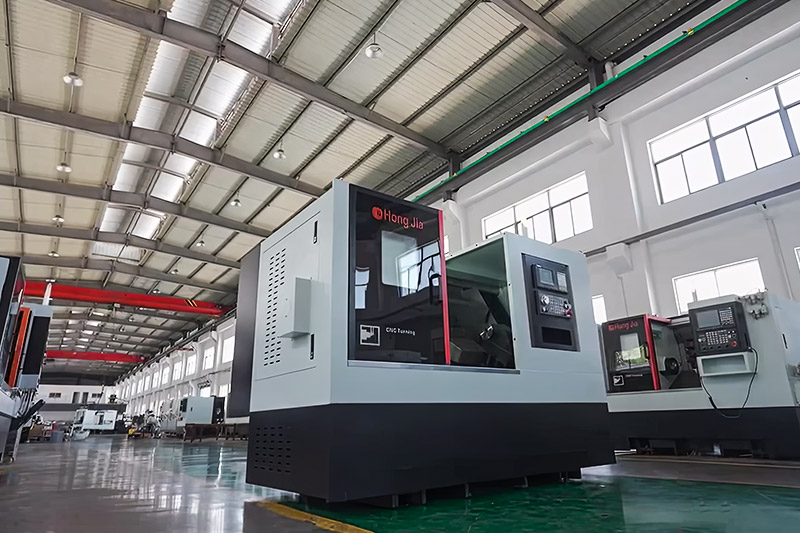

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China NC110 Precision Mechanical Spindle Horizontal Turning Center supplier and custom NC110 Precision Mechanical Spindle Horizontal Turning Center company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE -

How does High-Speed Precision Turning And Milling Machine achieve micron-level machining accuracy?

In high-end manufacturing, micron-level (μm) machining accuracy is the gold standard for measuring equipment performance. A qualified High-Speed Precision Turning And Milling Machine not only needs to achieve an ultra-...

READ MORE

Industry knowledge

Among the core components of the Precision Mechanical Spindle Horizontal Turning Center produced by Ningbo Hongjia CNC Technology Co., Ltd, the hydraulic three-jaw chuck is undoubtedly the most eye-catching one. This lathe adopts advanced hydraulic drive technology, and provides a stable and powerful clamping force for the three-jaw chuck through a precisely designed hydraulic system. Whether it is for the precision contour processing of complex parts or for high-speed drilling operations of high-strength materials, the hydraulic three-jaw chuck can lay a solid foundation for the entire processing process with its excellent performance.

Another highlight of the Precision Mechanical Spindle Horizontal Turning Center is its standard precision mechanical spindle, which has a built-in high-speed unit, is manufactured with advanced technology, and uses high-quality materials to ensure the dual advantages of high speed and high precision. The built-in high-speed unit enables the spindle to easily achieve high-speed rotation, perfectly adapting to the needs of high-speed cutting and drilling. Whether it is the pursuit of meticulous carving with micron-level precision or the pursuit of high-output mass production, the Precision Mechanical Spindle Horizontal Turning Center can meet the diverse needs of customers with stable and accurate processing results.

The processing capability of Precision Mechanical Spindle Horizontal Turning Center should not be underestimated. Its high-rigidity basic structure design enables the lathe to withstand the huge pressure brought by heavy cutting operations, ensuring the stability and durability of the processing process. Excellent cutting ability and stable processing accuracy enable Precision Mechanical Spindle Horizontal Turning Center to achieve efficient production while pursuing high-quality products. In addition, the lathe is also equipped with a removable coolant tank for easy cleaning and maintenance. The standard capacity is 125L, which effectively ensures the cleanliness and cooling effect of the processing environment.

In terms of configuration, Precision Mechanical Spindle Horizontal Turning Center also demonstrates Ningbo Hongjia CNC Technology Co., Ltd's unremitting pursuit of technological innovation. The standard configuration of the new generation SYTEC/22TA control system, the new generation drive motor and the high-torque servo spindle motor ensure the leading position of the lathe in control accuracy, power output and response speed. At the same time, the use of linear rails and lead screws imported from Taiwan or Japan further improves the accuracy and durability of the lathe. The independent water tank design, efficient chip removal device and standard hydraulic three-jaw chuck together constitute the powerful processing system of Precision Mechanical Spindle Horizontal Turning Center, providing users with a full range of solutions.

As a leader in the field of CNC metal cutting equipment in China, Ningbo Hongjia CNC Technology Co., Ltd. has continuously promoted the innovation and development of CNC technology with its strong technical strength and rich industry experience. The successful launch of Precision Mechanical Spindle Horizontal Turning Center is a concentrated reflection of the company's technological innovation capabilities and market insight.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى