Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / Products / Horizontal CNC turning and milling series / NC108D-Y Drawout Coolant Tank Horizontal Turning Center

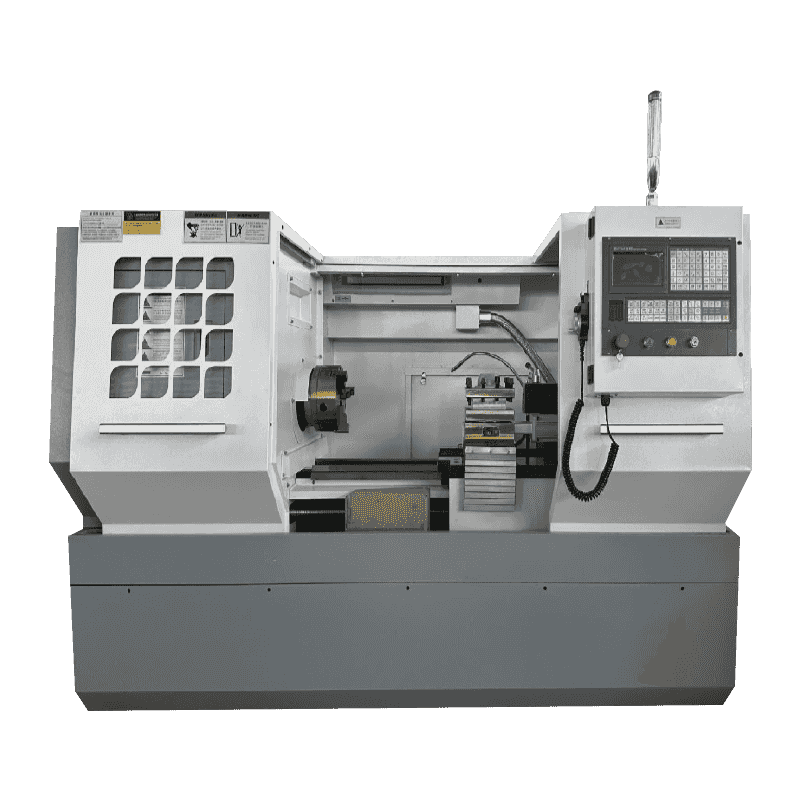

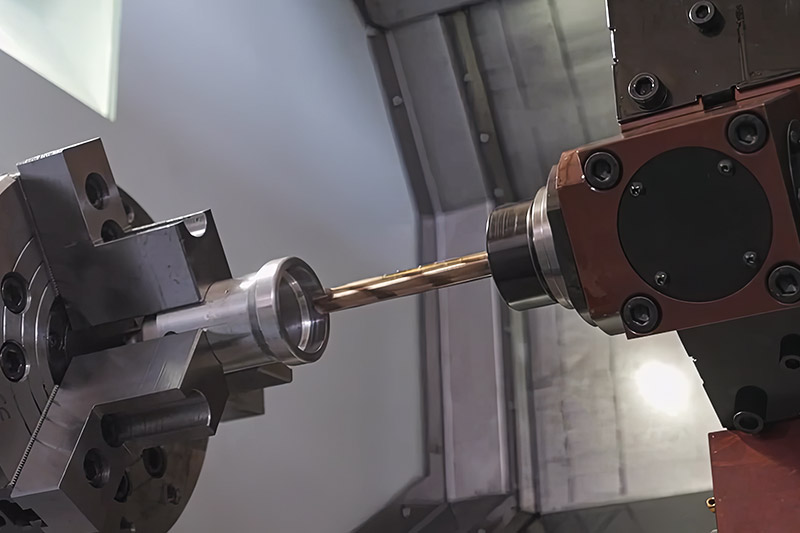

Home / Products / Horizontal CNC turning and milling series / NC108D-Y Drawout Coolant Tank Horizontal Turning Center NC108D-Y Drawout Coolant Tank Horizontal Turning Center

The horizontal turning center with a pull-out coolant tank separates the cutting fluid storage from the machine tool body, effectively avoiding the potential corrosion risk of the cutting fluid on the precision parts of the machine tool, and greatly reducing the machine tool failure rate caused by cutting fluid leakage. The independent water tank not only enhances the overall protection performance of the machine tool, but also keeps the machine tool body dry and clean, extending the service life of the equipment.

The equipped efficient chip removal system is the key to improving processing efficiency and keeping the machine tool clean. The system adopts advanced chip removal technology and structural design, which can quickly and accurately remove various chips generated during the processing, effectively avoiding machine tool failures and reduced processing accuracy caused by chip accumulation.

The working principle of the efficient chip conveyor is simple and efficient. During the processing, the chips are quickly collected and transported to the designated collection area through the chip removal pipe. During this process, the chip conveyor can intelligently identify the chip type and size, adjust the chip removal speed and force, and ensure the best chip removal effect. At the same time, the chip conveyor has low operating noise and will not interfere with the operating environment.

Production Information

Processing Capacity

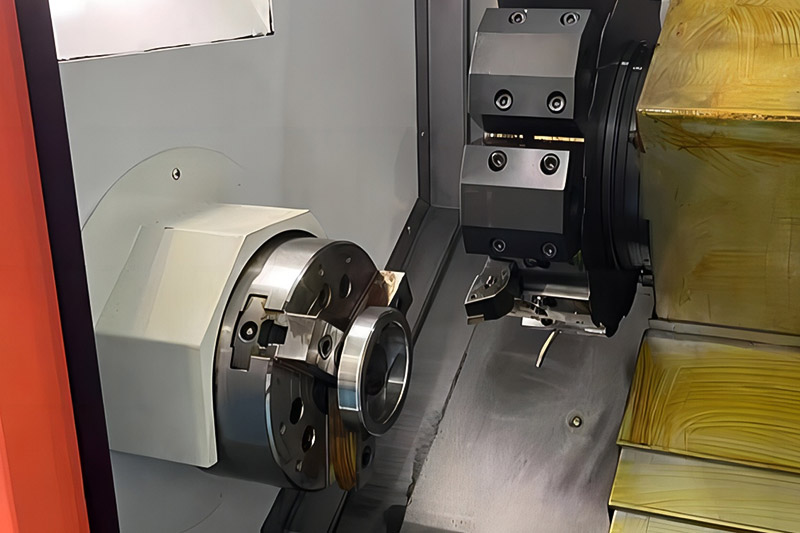

1. Lathe, drilling, and boring can be carried out

2. High rigidity basic structure, to achieve heavy cutting

3. Excellent cutting ability and stable processing accuracy to achieve high production

4. The draw-out coolant tank is used for easy cleaning and cutting

5. Standard tank capacity: 125L

Machine tool basic configuration

1. New generation SYTEC/22TB

2. New generation drive motor

3. The new generation of high torque servo spindle motor is standard

4. Taiwan or Japan wire rail and screw

5. Separate water tank

6. Chip removal machine

7. Oil pressure three claws

8. Standard with built-in high-speed unit precision mechanical spindle

Technical Parameter

| Item | Unit | NC-108D-Y | |

| Max. Turning the diameter on the bed | mm | Φ650 | |

| Max. machining diameter (disc type) | mm | Φ300 | |

| Max .machining diameter (shaft type) | mm | Φ350 | |

| Max. turning diameter on a skateboard | mm | Φ280 | |

| Distance between two centers | mm | 500 | |

| Max. working length | mm | 460 | |

| Max. Tie rod through hole diameter | mm | Φ52 | |

| Principal axis | Spindle nose form | A2-6 | |

| Spindle through hole diameter | mm | Φ66 | |

| The taper of the spindle inner hole | MT-6 | ||

| Three-jaw chuck holding capability | 8" | ||

| Pull rod action form | Hydraulic pressure | ||

| Max. spindle speed | r/min | 4000 | |

| Main motor power | kW | 11/15 | |

| Feed | X-axis travel | mm | 225 |

| Z-axis travel | mm | 490 | |

| X/Z axis fast-moving speed | m/min | 25 | |

| Precision | Positioning accuracy (X/Z) | mm | 0.008/0.010 |

| Repeated positioning accuracy (X/Z) | mm | 0.006/0.008 | |

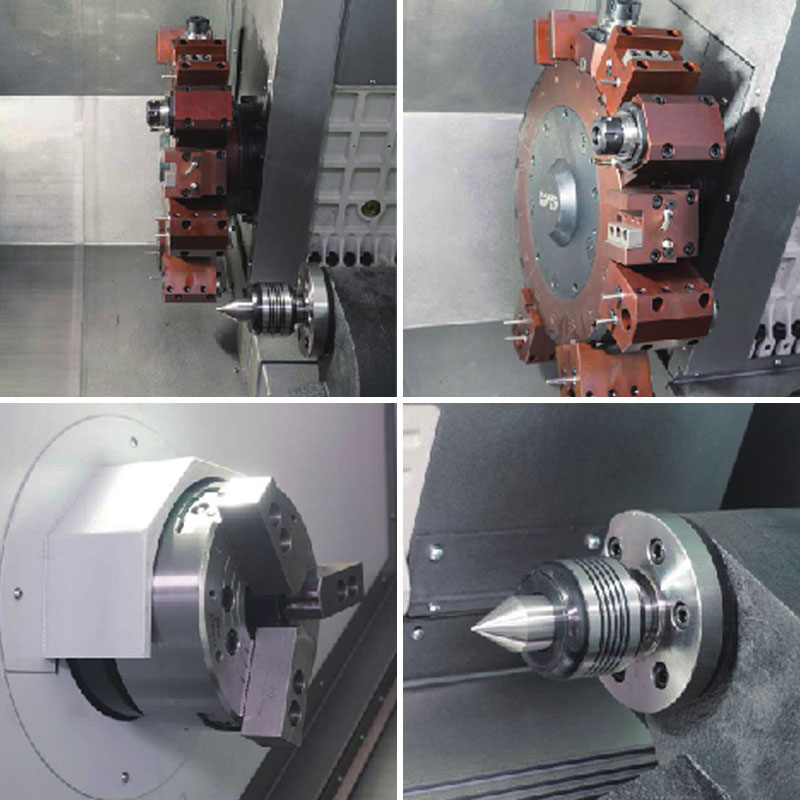

| Power tool tower | Tool number | 12 | |

| Driving form | servo | ||

| Height of center | mm | 170 | |

| Tool change time (T-T) | s | 0.2 | |

| Boring tool holder specifications | mm | 32 | |

| Square tool holder specifications | mm | 25 | |

| Powerhead speed | r.p/min | 4000 | |

| Power head motor power | KW | 3.6 | |

| Powerhead torque | N.m | 15 | |

| Powerhead type | BMT | 55 | |

| Y-axis | Y-axis travel | mm | 100 |

| Y-axis motor torque | N.m | 8.4 | |

| Y-axis screw | balls | 3206 | |

| Y-axis guide form | Rectangular Hard Rails / Wire Rails | Rectangular hard rail | |

| Tailstock | Taper of tailstock sleeve | MT-5 | |

| Max/Min. holding workpiece length | mm | 500/60 | |

| Safety shield | Completely closed | ||

| Numerical control system | SYTEC22TB/ FANUC 0i-TF/ GSK988TA | ||

| Machine weight | Kg | ≈4400 | |

| Overall dimensions of the machine (LxWxH) | mm | 2420X1700X2050 | |

Recommended Products

Keep in Touch

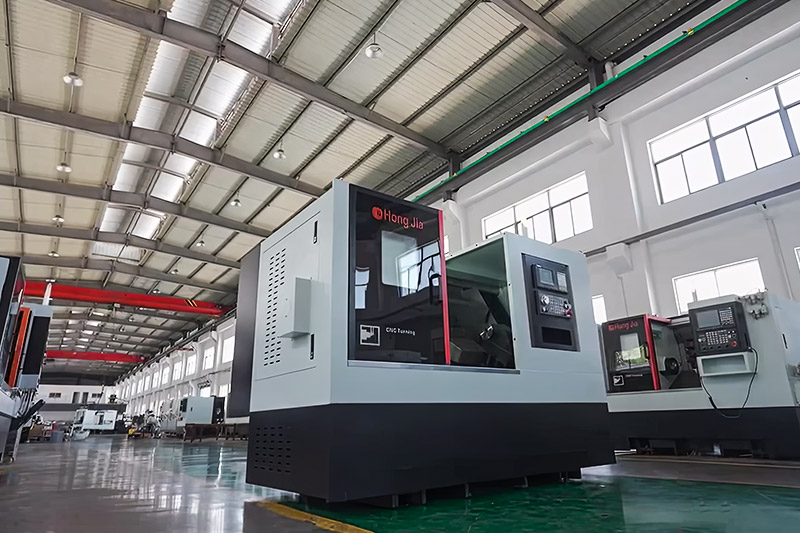

Ningbo Hongjia CNC Technology Co., Ltd.

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China NC108D-Y Drawout Coolant Tank Horizontal Turning Center supplier and custom NC108D-Y Drawout Coolant Tank Horizontal Turning Center company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE -

How does High-Speed Precision Turning And Milling Machine achieve micron-level machining accuracy?

In high-end manufacturing, micron-level (μm) machining accuracy is the gold standard for measuring equipment performance. A qualified High-Speed Precision Turning And Milling Machine not only needs to achieve an ultra-...

READ MORE

Industry knowledge

What are the unique features of the Drawout Coolant Tank Horizontal Turning Center?

1. Innovative coolant system design

A major highlight of the Drawout Coolant Tank Horizontal Turning Center is its innovative coolant system design. Traditional lathe coolant systems often have problems such as poor cooling effect and difficult maintenance. The coolant tank of this lathe adopts a removable design, which is not only convenient for daily maintenance and cleaning, but also ensures that the coolant is always clean, thereby improving cooling efficiency and machining accuracy. At the same time, the coolant is evenly sprayed on the workpiece and tool through a precise nozzle, effectively reducing the cutting temperature and extending the service life of the tool.

2. High-precision horizontal rotation function

Another unique feature of the Drawout Coolant Tank Horizontal Turning Center is its high-precision horizontal rotation mechanism. This design enables the lathe to easily achieve precise rotation and positioning of the workpiece, thereby meeting the processing needs of complex parts. During the processing process, the spindle and tailstock of the lathe can move synchronously to ensure that the workpiece remains stable during rotation.

Ningbo Hongjia CNC Technology Co., Ltd's CNC lathe products also excel in precision control. These lathes are also equipped with advanced CNC systems, which can achieve precise control and adjustment of processing parameters, further improving processing efficiency and workpiece quality.

3. Powerful processing capabilities and adaptability

Drawout Coolant Tank Horizontal Turning Center also has powerful processing capabilities and wide adaptability. Whether it is processing large workpieces or small parts, this lathe can easily cope with it. Its sturdy bed structure and precise transmission system ensure the stability and precision of the lathe at high speed. At the same time, the lathe also supports a variety of tool and fixture configurations, allowing it to adapt to different materials and processing requirements.

Ningbo Hongjia CNC Technology Co., Ltd's CNC lathe products are also commendable in terms of processing capabilities and adaptability. These lathes can process various complex shapes of parts, such as shafts, discs, sleeves, etc. At the same time, they also support a variety of processing methods, such as turning, milling, drilling, boring, etc., further expanding the application range of lathes.

4. Intelligent operation and monitoring

With the development of intelligent manufacturing technology, Drawout Coolant Tank Horizontal Turning Center has also incorporated intelligent elements. Modern lathes are equipped with advanced CNC systems and human-computer interaction interfaces, allowing operators to easily set, monitor and adjust processing parameters. At the same time, the lathe also supports remote monitoring and fault diagnosis functions, which can reflect the operating status and abnormal conditions of the lathe in real time, facilitating timely maintenance and maintenance.

Ningbo Hongjia CNC Technology Co., Ltd has also achieved remarkable results in the intelligence of CNC lathes. Their lathes are equipped with advanced CNC systems and sensor technology, which can monitor various parameters and status information during the processing process in real time. This information can be displayed and recorded through the human-computer interaction interface, which is convenient for operators to analyze and adjust.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى