Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / News / Industry News / High-rigidity horizontal turning center: a new generation of power innovation for precision manufacturing

Home / News / Industry News / High-rigidity horizontal turning center: a new generation of power innovation for precision manufacturing High-rigidity horizontal turning center: a new generation of power innovation for precision manufacturing

2025.04.10

2025.04.10

Industry News

Industry News

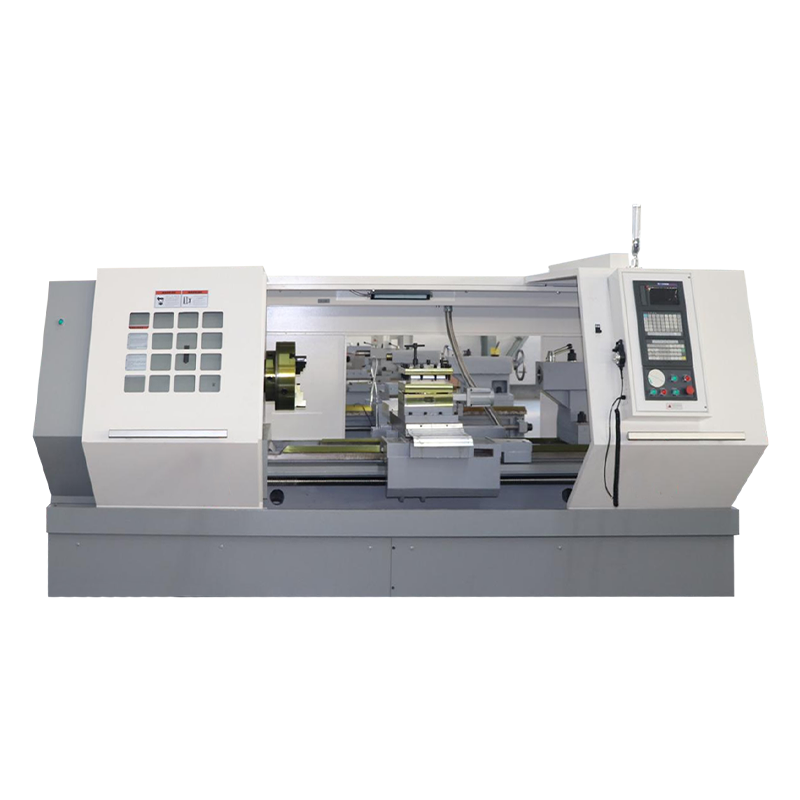

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced programming technology. This type of machine covers the full-size processing needs from tiny parts to large and heavy-loaded workpieces, and has achieved a double breakthrough in efficiency and precision through the combination of a new generation of high-torque servo spindle motors and high-speed spindle technology.

The core competitiveness of the high-rigidity horizontal turning center is first reflected in its mechanical structure design. Its standard new generation of high-torque servo spindle motors is the core of its powerful cutting ability. The motor not only has strong power output, but also has high torque performance, which can easily cope with material processing and heavy cutting tasks.

The application of high-speed spindles significantly shortens the processing cycle and improves production efficiency. In the processing of lightweight materials such as aluminum alloys and composite materials, high-speed rotating spindles can quickly remove materials with less cutting force, so that the surface roughness can be controlled within the standard, while improving processing efficiency.

With the continuous development of industrial technology, high-rigidity horizontal turning centers are evolving towards intelligence. This type of technological evolution not only reconstructs the traditional manufacturing process, but also provides underlying support for more efficient production.

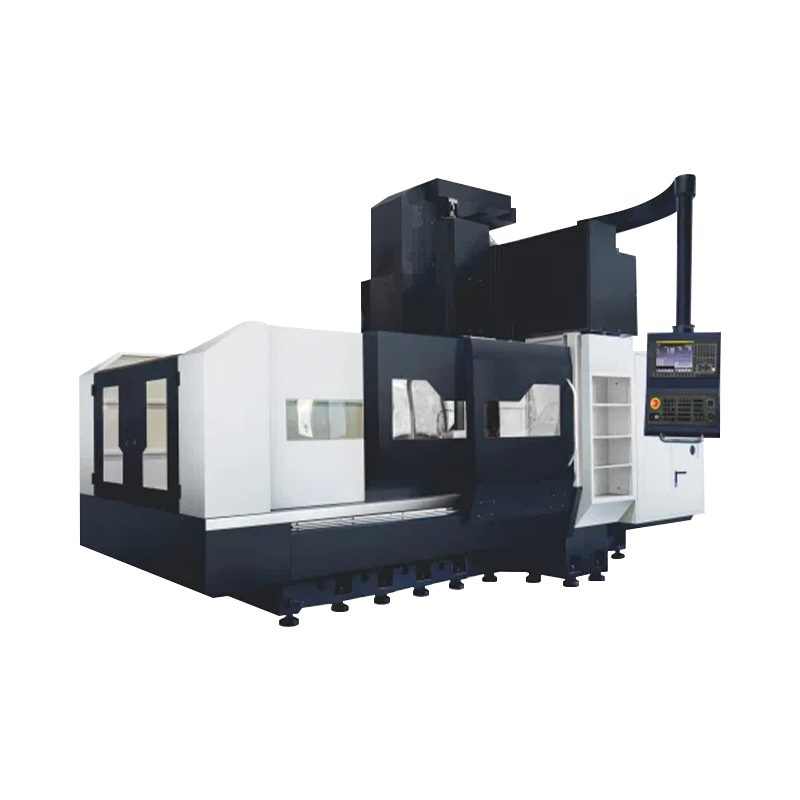

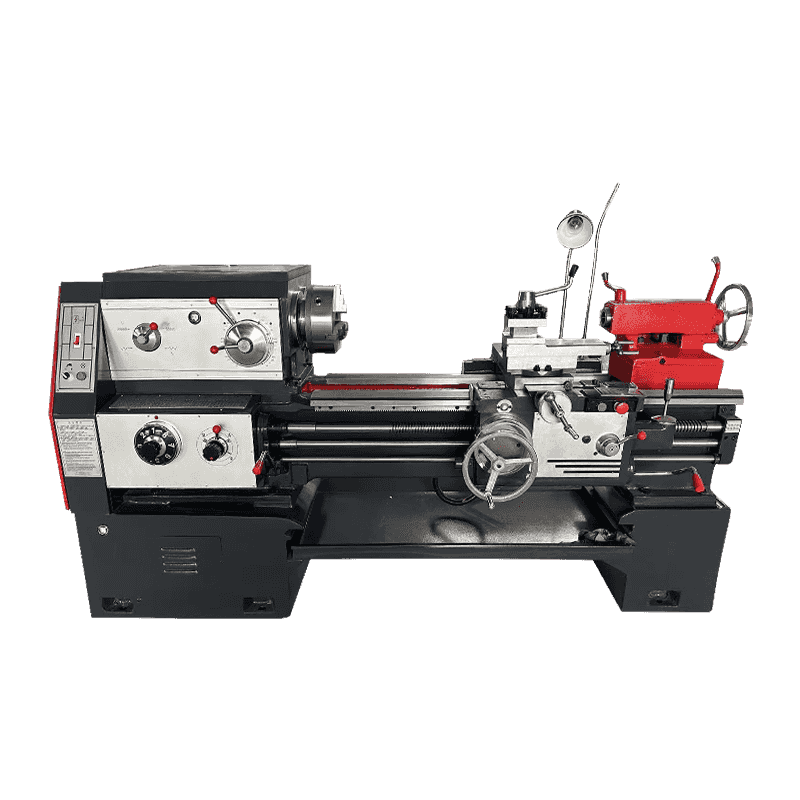

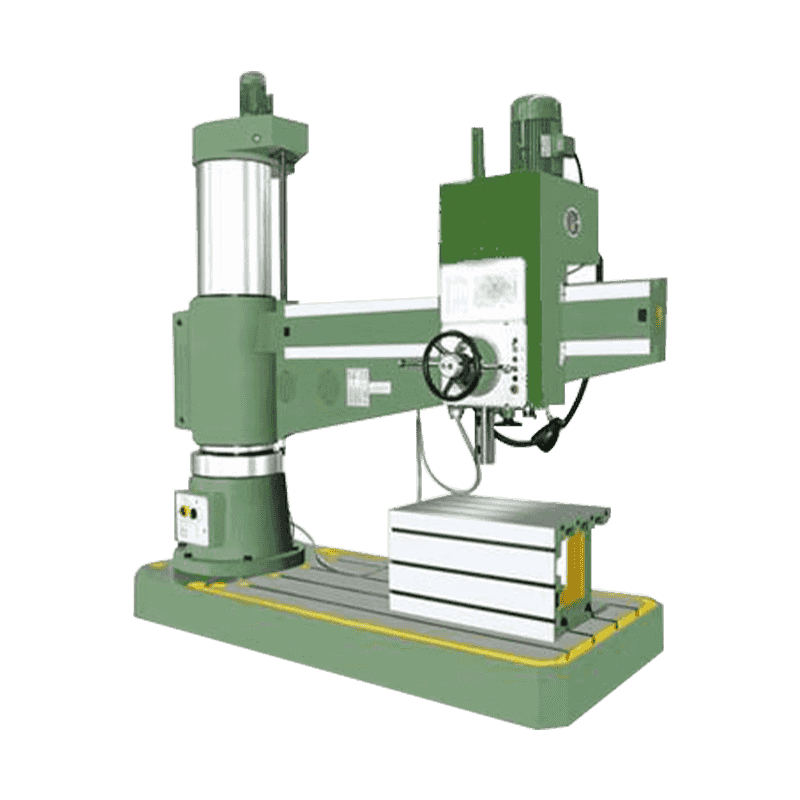

Recommended Products

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى