Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / Products / Ordinary turning, milling and drilling machine series / CA6140 Series Ordinary Lathe

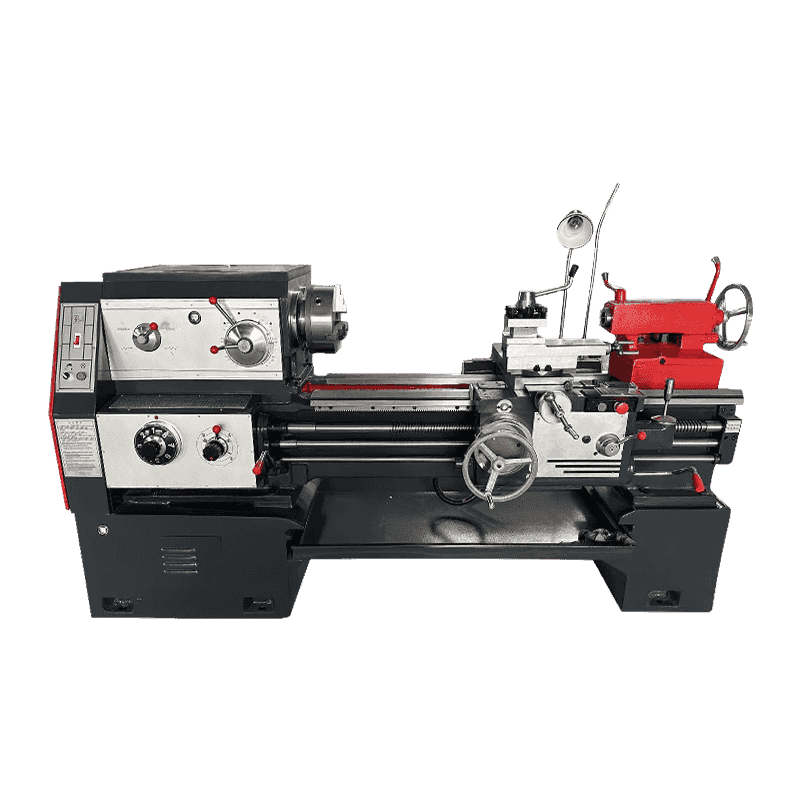

Home / Products / Ordinary turning, milling and drilling machine series / CA6140 Series Ordinary Lathe CA6140 Series Ordinary Lathe

Machine outline:

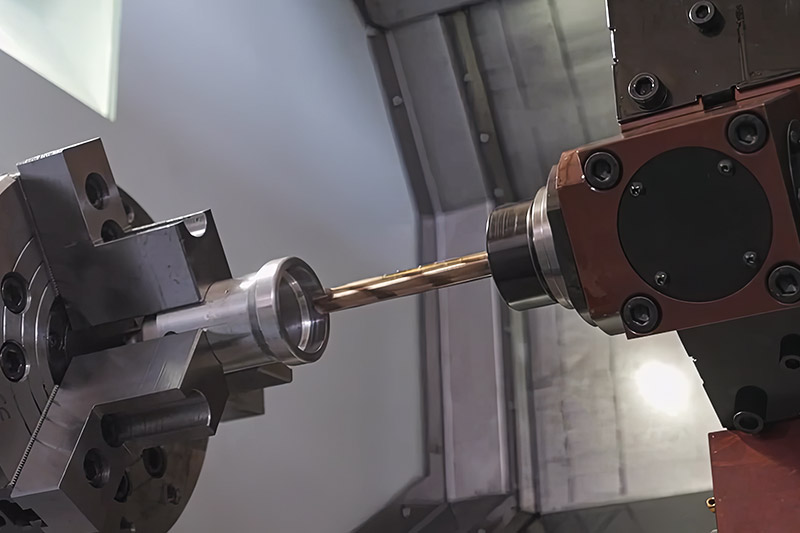

CA6140 series ordinary horizontal lathe is suitable for turning internal and external cylindrical surfaces, conical surfaces, and other rotating surfaces, turning a variety of metric, imperial, modular, and diameter pitch threads, and can drill and pull oil groove and other work, is a very versatile horizontal lathe, widely used in a variety of shaft and disk parts batch processing. The lathe bed is wider than the general lathe, the guide rail width of 400mm has high stiffness, and the guide rail surface by medium frequency quenching and durable wear. The operation of the machine tool is convenient and centralized, and the slide plate is equipped with a fast-moving mechanism. Using a single-handle visualization operation is a good amenity. The structural stiffness and transmission stiffness of the machine tool is higher than that of the general lathe, and the power utilization rate is high, which is suitable for strong cutting. The machine tool is inspected in strict accordance with the inspection procedure before leaving the factory, and the strong cutting test is done to ensure that the machine tool has good precision stability and processing reliability.

Production Information

Advantages of machine tools

1. Machine headboard and bed. Tail seat, bracket, and other combination surfaces between the manual scraping, and the whole machine through strict testing, effectively ensure the accuracy and stability of the machine.

2. The machine adopts high-strength cast iron, adding special materials of copper and chromium, the width of the bed guide rail is 400mm, and the quenching depth of the bed guide rail is 4mm, which effectively improves the wear resistance and stability of the machine tool.

3. The machine headstock lubrication adopts a cycloidal pump for circulation and forced lubrication, which ensures the cleanliness and heat dissipation characteristics of the headstock for hot weather in the south, and effectively extends the service life of bearings and gears.

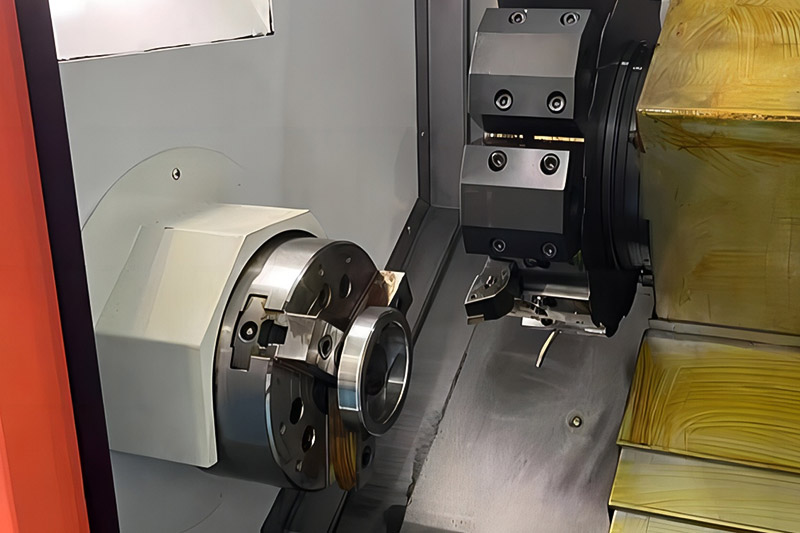

4. The spindle of the machine tool adopts a Wafangdian bearing, the spindle through hole φ52mm, and the machine tool gear adopts precision grinding, which effectively improves the hardness of the gear and reduces the machine noise.

5. The machine adopts a domestic brand screw, and the wire mother adopts high-quality bronze alloy to ensure wear resistance and accuracy.

6. The machine adopts a four-station high-strength tool rest, and the tool handle size is 25x25mm

Main technical parameters

| Technical parameter | unit | CA6140×1000/1500/2000 | ||

| Maximum workpiece rotation diameter on the bed | mm | 400 | ||

| Maximum workpiece turning diameter on the tool holder | mm | 210 | ||

| Bed width | mm | 400 | ||

| Maximum workpiece length | mm | 1000/1500/2000 | ||

| Arbor section | mm | 25×25 | ||

| Spindle front taper hole | Mohs | No.6 | ||

| Feed quantity | Kind of 64 | |||

| Spindle speed range (series) | r/min | 10-1600/16-1600(24level) | ||

| Spindle through hole diameter | mm | 52,80 | ||

| Metric thread range (number) | mm | 1-192mm(Kind of 44) | ||

| Inch thread range (types) | Teeth per hour | 2-24tpi(Kind of 21) | ||

| Modular thread | 0.25-48(The modulus is 39 kinds) | |||

| Pitch thread | 1-96DP(Kind of 37) | |||

| Maximum travel of tailstock spindle | mm | 150mm | ||

| Taper of the main shaft hole of the tail seat | Mohs | Mohs 5 | ||

| Tailstock spindle diameter | mm | 75 | ||

| Main motor power | kw | 7.5 | ||

| Machine weight | kg | Gross weight | Net weight | |

| Length1000mm | 2190 | 2070 | ||

| Length1500mm | 2350 | 2220 | ||

| Length2000mm | 2720 | 2570 | ||

| Package size | mm | |||

| Length 1000mm | 2700×1140×1750 | |||

| Length 1500mm | 3200×1140×1750 | |||

| Length 2000mm | 3700×1140×1750 | |||

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

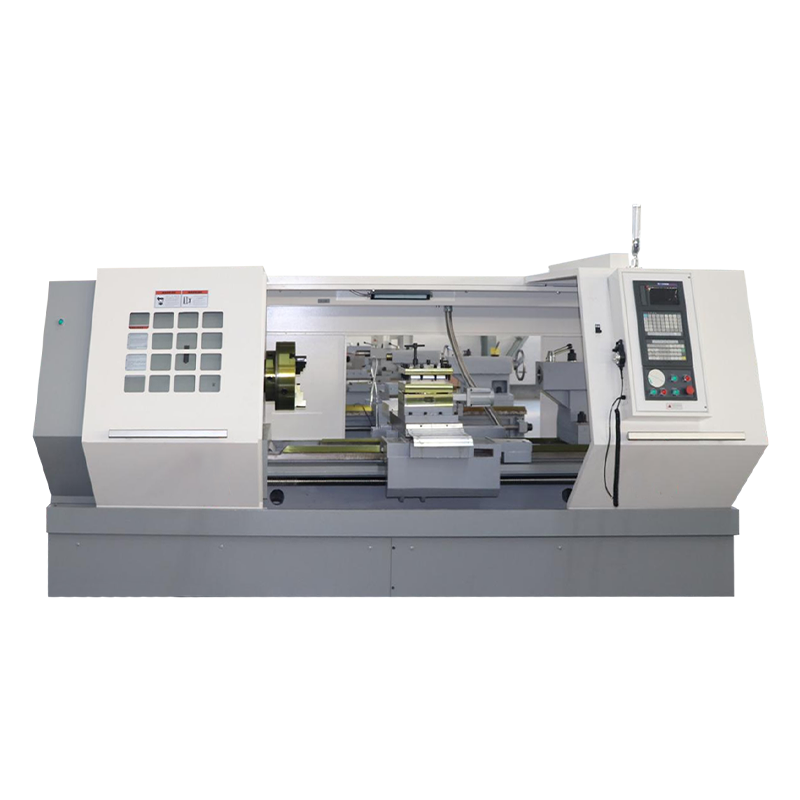

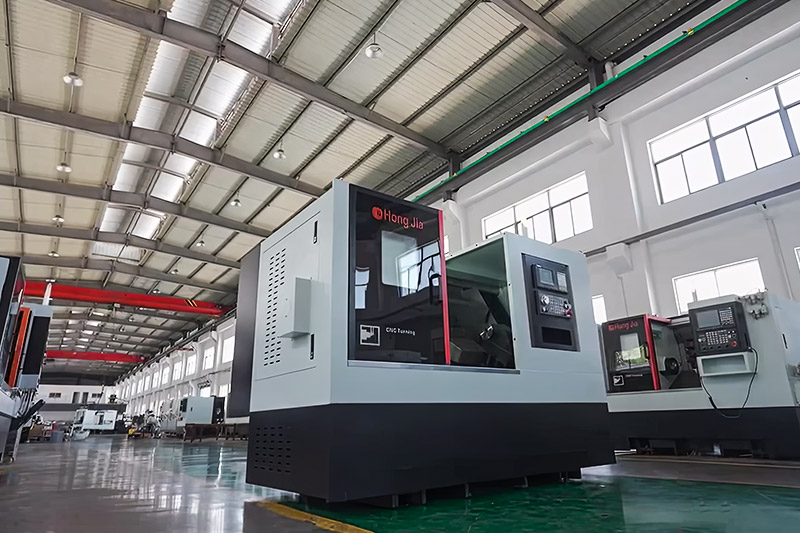

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China CA6140 Series Ordinary Lathe supplier and custom CA6140 Series Ordinary Lathe company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE -

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE

Industry knowledge

CA6140 Series Ordinary Lathe: An Efficient Model of Precision Manufacturing

Hongjia CNC: Professional Manufacturing, Leading Innovation

Ningbo Hongjia CNC Technology Co., Ltd, a high-tech enterprise integrating R&D, production and sales, focuses on the innovation and development of CNC metal cutting equipment. As a professional supplier and custom factory of CA6140 Series Ordinary Lathe, Hongjia CNC is committed to providing advanced CNC solutions to global customers with its strong technical strength and rich industry experience to meet the diverse needs of customers in different industries. The company not only focuses on the technological innovation and upgrading of products, but also emphasizes the personalization and customization of services to ensure that every customer can obtain the machine tools and equipment that best suits their production needs.

CA6140 Series: Versatile and High-Efficiency

The CA6140 Series Ordinary Lathe has become a versatile player in the field of mechanical processing with its wide range of processing adaptability. This series of lathes is suitable for turning of internal and external cylindrical surfaces, conical surfaces and other rotating surfaces, and can easily cope with various metric, imperial, module and diametral pitch thread turning tasks. In addition, it also has additional functions such as drilling and oiling, which makes it extremely flexible and efficient in batch processing of shaft and disc parts. Its design fully considers the convenience in actual operation. The machine operation is centralized, the slide is equipped with a fast moving mechanism, and the single handle visual operation is adopted, which greatly improves the comfort and work efficiency of the operator.

Structural optimization and strong durability

CA6140 Series Ordinary Lathe has made many structural optimizations, which makes it have higher structural rigidity and transmission rigidity than traditional lathes. The width of the machine bed exceeds the conventional design, and the width of the guide rail reaches 400mm, which ensures the high rigidity and stability of the machine tool. The surface of the guide rail is treated with medium frequency quenching, which greatly improves the wear resistance and prolongs the service life.

Precision manufacturing, quality assurance

Hongjia CNC knows that an excellent lathe is not only a pile of hardware, but also a crystallization of craftsmanship and quality. Therefore, each CA6140 Series Ordinary Lathe must undergo a strict inspection process before leaving the factory, including but not limited to precision testing, performance evaluation and strong cutting testing. These tests ensure that the machine tool can maintain high precision and processing reliability in actual applications, bringing customers continuous and stable processing benefits. Hongjia CNC's insistence on quality is not only reflected in the strict control of raw materials and manufacturing processes, but also in the high attention to after-sales service, ensuring that any problems encountered by customers during use can be solved promptly and effectively.

Widely used, value highlighted

CA6140 Series Ordinary Lathe has shown great value in aerospace, automobile manufacturing, precision instruments, mold manufacturing and other fields with its excellent versatility and efficiency. Whether it is small-scale trial production or large-scale batch production, it can provide stable and accurate processing solutions to help companies improve production efficiency, reduce costs and enhance market competitiveness. Especially in the context of the increasingly obvious trend of intelligent manufacturing, Hongjia CNC is actively exploring the combination of CA6140 Series Ordinary Lathe with advanced technologies such as the Internet of Things and big data to promote the transformation of traditional machine tools towards intelligence and networking, so as to meet the higher requirements of flexibility and intelligence in the future manufacturing industry.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى