Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

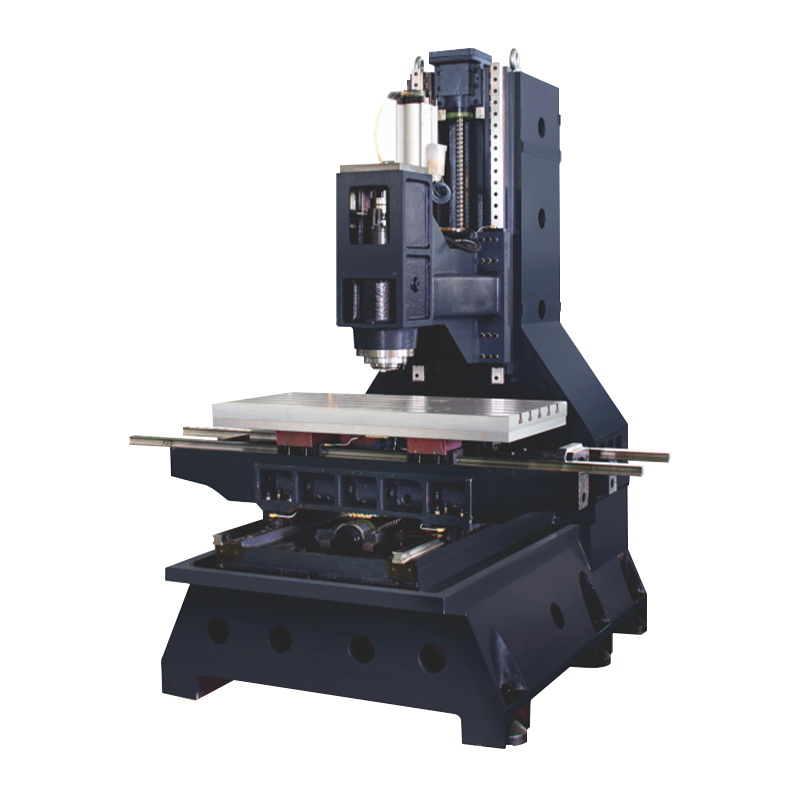

Vertical Machining Centre

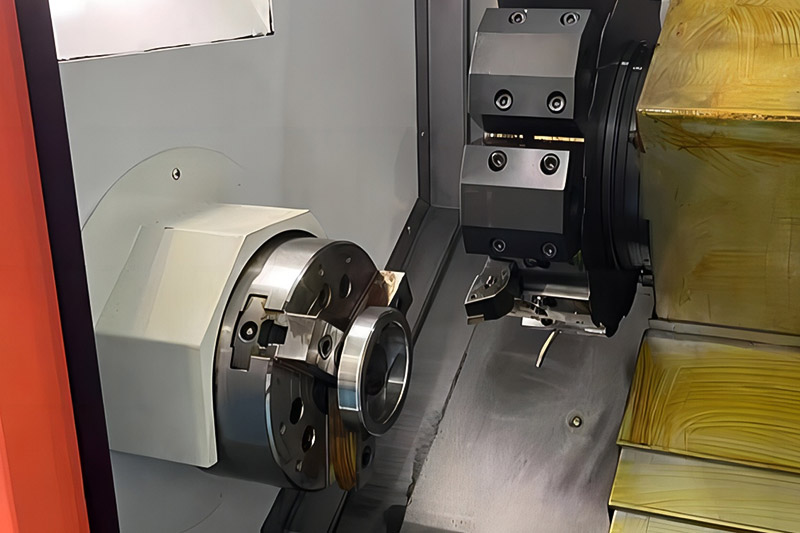

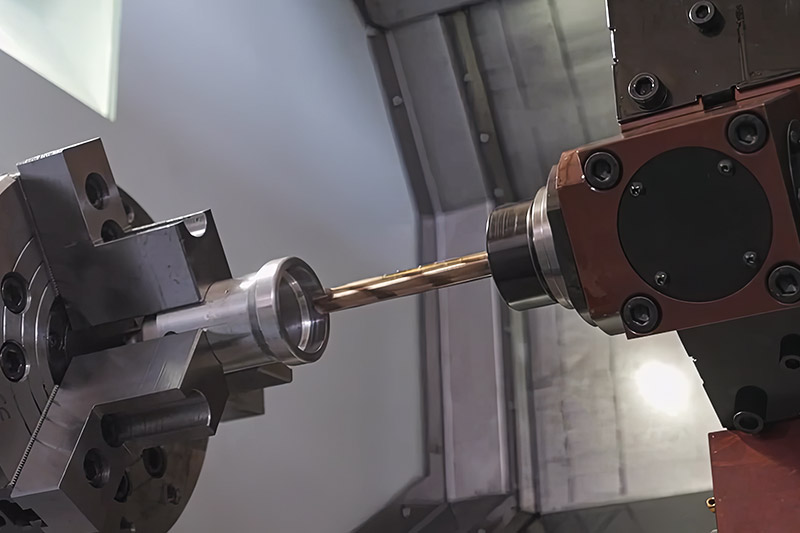

The vertical machining center is a high-performance CNC machining equipment suitable for precision machining of complex parts. It adopts a high-precision C3-level ball screw and rolling guide system, equipped with P4-level bearings and precision Speedcn couplings to ensure high rigidity and precise positioning of the three axes. Equipped with Speedcn short-nose spindle and protective cover, it provides stable cutting performance and protection functions. The machining center also has a fully automatic tool changing system and an optional nitrogen balancing device to improve machining efficiency and machining accuracy. In addition, the optional high-speed spindle, cooling water system and nitrogen balancing device further enhance its performance in high-load and high-precision machining.

Production Information

Main Configurations

Three axes adopt ‘PMI or HIWIN’ or ‘THK’ C3 grade ball screws.

Three axes with ‘PMI or HIWIN’ or ‘THK’ roller guideways.

V6/V7 with ‘Rexroth’ or ‘Shangyin’ or ‘Yintai’ or ‘THK’ ball screws (Z-axis) Roller)

P4 grade bearings for all three axes

Three-axis ‘Speedcn’ couplings

‘Speedcn’ short nose spindles

Three-axis ‘Speedcn’ guards

Volumetric oiler

Cylinders (direct spindle with booster cylinder)

Toolbox and adjustment tools

Optional Configurations

BBT40-Ф120-15000 rpm direct type ‘Speedcn’ long nose spindle

BBT40-Ф155-12000rpm direct type ‘Speedcn’ short nose spindle

BT40-24T ‘Yitai tool changer’.

Nitrogen counterweight

Spindle upgraded center water (belt type with rotary joint / direct type without rotary joint)

Technical Parameters

| Specification | Unit | V6 | V7 | V8 | V10 | V1270 | V1370 | V1380 | V1570 |

| X/Y/Z travel | mm | 600*450*450 | 700*450*450 | 800*500*500 | 1000*600*600 | 1200*700*700 | 1300*700*700 | 1300*800*700 | 1500*700*700 |

| Table area | mm | 700*420 | 800*420 | 1000*500 | 1100*500 | 1400*700 | 1400*700 | 1400*800 | 1600*700 |

| Maximum table load | kg | 250 | 250 | 450 | 450 | 700 | 700 | 700 | 1100 |

| Distance from spindle nose to table | mm | 135-585 | 135-585 | 120-670 | 120-750 | 120-820 | 120-820 | 120-820 | 150-850 |

| Distance from spindle centre to column track surface | mm | 488 | 488 | 550 | 655 | 770 | 770 | 860 | 800 |

| Table T-slot | mm | 14T*3*125 | 14T*3*125 | 18T*5*80 | 18T*5*100 | 18T*5*125 | 18T*5*125 | 18T*5*125 | 18T*5*125 |

| Spindle taper hole/diameter | r/min | BBT40(Ф120) | BBT40(Ф120) | BT40(Ф155) | BT40(Ф155) | BT40(Ф155) | BT40(Ф155) | BT40(Ф155) | BT40(Ф155) |

| Spindle speed | r/min | Standard:12000 Direct Option:15000 Direct | Standard:12000 Direct Option:15000 Direct | Standard:12000 direct type Option:8000 belt type Option:10000 belt type Option:15000 direct type | Standard:12000 direct type Option:8000 belt type Option:10000 belt type Option:15000 direct type | Standard:8000 Direct Option:10000 belt type Option:12000 belt type Option:15000 direct type |

|||

| (X/Y/Z) Rapid traverse | m/min | 48 | 48 | 48 | 36 | 36 | 36 | 36 | 24 |

| Z-axis counterweight | /mm | No counterweight | No counterweight | No counterweight | Option: Nitrogen counterweight | Option: Nitrogen counterweight | Option: Nitrogen counterweight | Option: Nitrogen counterweight | Option: Nitrogen counterweight |

| Ball screw | mm Standard | XY: 28*16 single nut Z: 32*16 double nut | XZ: 32*16 double nuts Y: 28*16 single nuts | XZY: 36*16 single nut | XZY: 40*12 double nuts | XZY: 40*12 double nuts | XZY: 40*12 double nuts | XZY: 40*12 double nuts | XZY: 40*12 double nuts |

| mm Optional | XY: 28*12 single nut Z: 32*12 double nut | XZ: 32*16 single nut Y: 28*16 single nut | |||||||

| Linear guideway (width of linear guideway/number of sliders) | mm | XY:30*2 Z:35*2 | XY:30*2 Z:35*2 | XYZ: 35*2 | X: 35*2 YZ: 45*2 | XZ: 45*3 Y: 45*2 | XZ: 45*3 Y: 45*2 | XZ: 45*3 Y: 45*2 | XZ: 45*3 Y: 45*2(4 rails) |

| Machine weight | kg | About 2700 | Approx. 2750 | Approx. 3100 | Approx. 3800 | Approx. 4800 | Approx. 5000 | Approx. 5200 | Approx. 6000 |

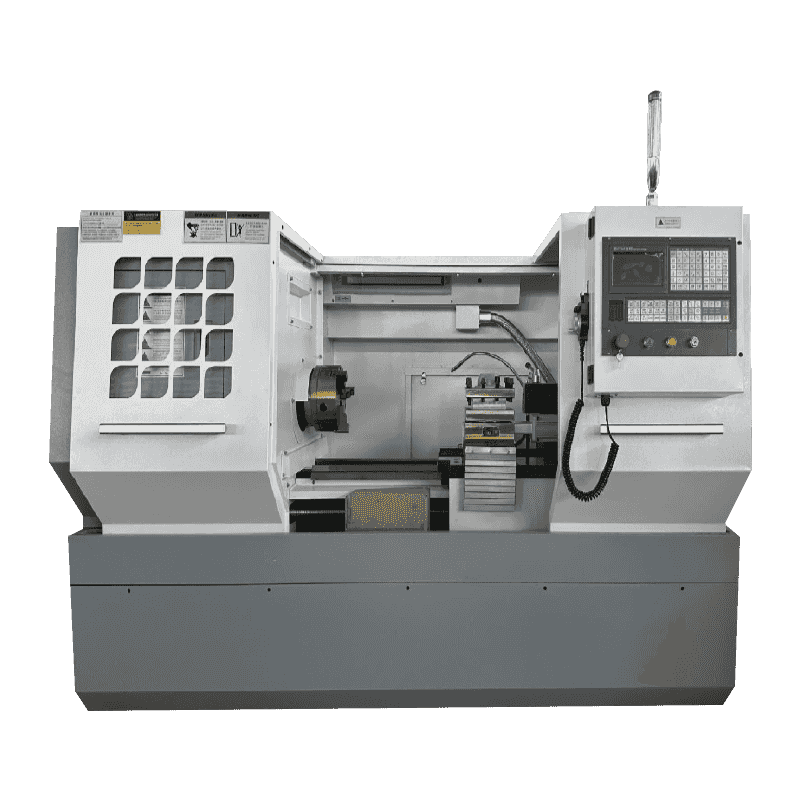

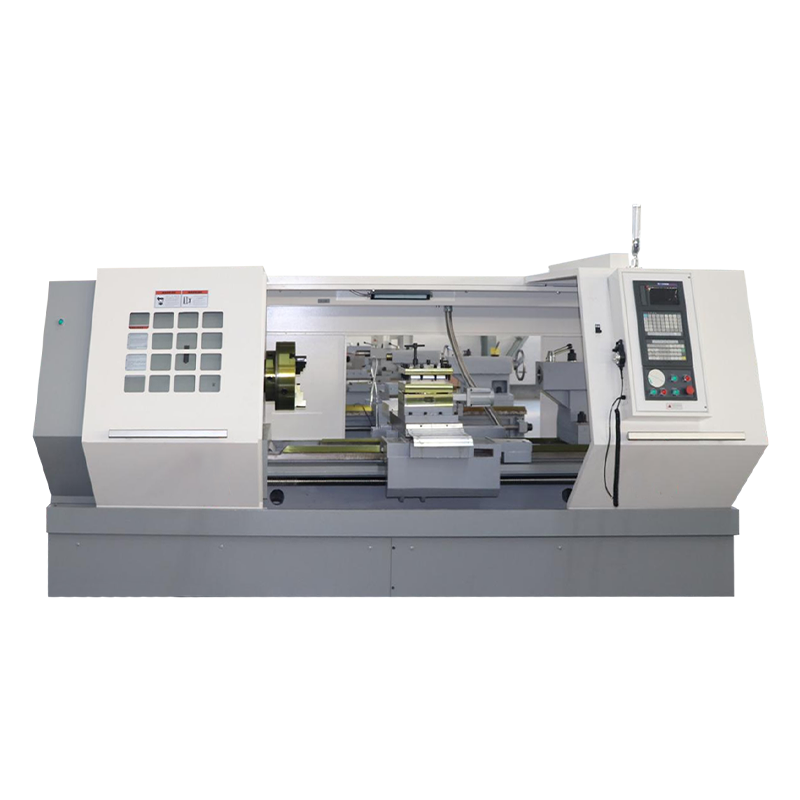

Recommended Products

Keep in Touch

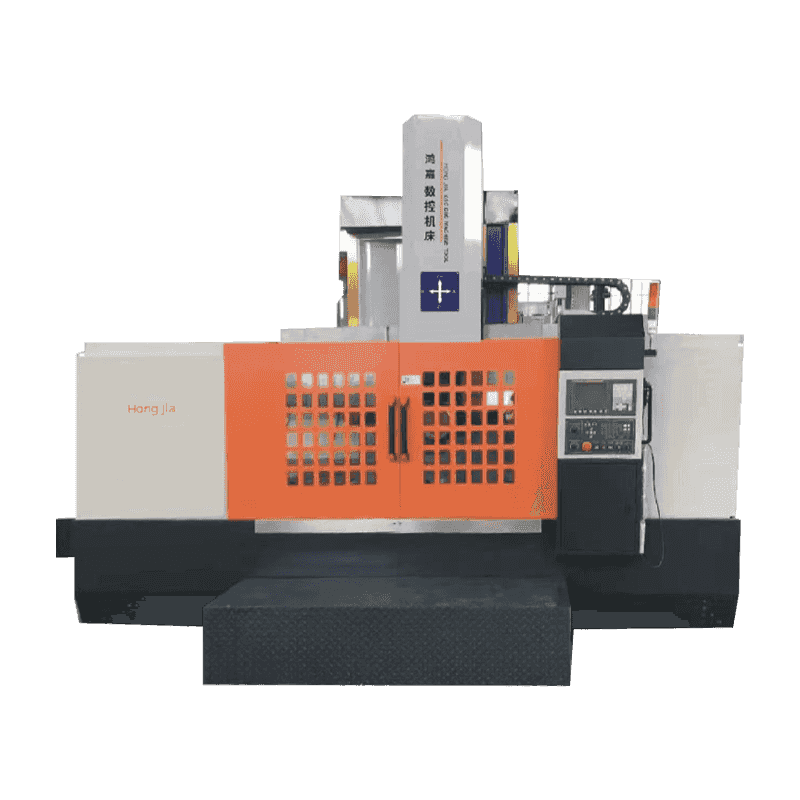

Ningbo Hongjia CNC Technology Co., Ltd.

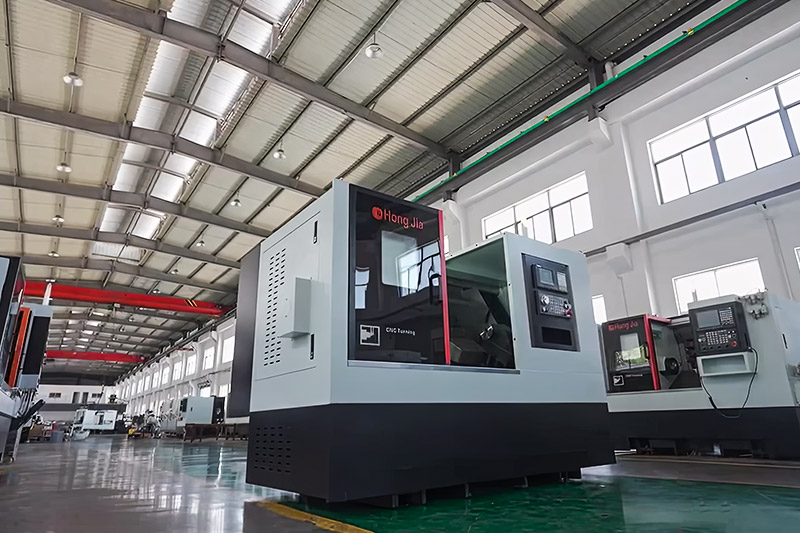

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China Vertical Machining Centre supplier and custom Vertical Machining Centre company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

In the wave of industrial manufacturing, low-noise CNC horizontal lathes not only continue the rigorous process of traditional mechanical processing, but also incorporate innovative materials and intelligent design, whil...

READ MORE -

As the core system of precision machining equipment, the standardization of post-use cleaning and post-maintenance of the Drawout Coolant Tank Horizontal Turning Center directly affects the machining accuracy, tool life ...

READ MORE -

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE

Industry knowledge

Vertical Machining Centre: A smart tool for precision manufacturing

Vertical Machining Centre, as a high-performance CNC processing equipment, is particularly suitable for precision processing of complex parts. It not only integrates the essence of modern CNC technology, but also ensures high stability and high precision of the processing process through the optimized configuration of a series of precision components. The Vertical Machining Centre produced by Ningbo Hongjia CNC Technology Co., Ltd adopts C3-level high-precision ball screws and rolling guide rails. This configuration greatly improves the rigidity and three-axis positioning accuracy of the machine tool. At the same time, with P4-level bearings and Speedcn precision couplings, the stability and accuracy of the processing process are ensured, providing a solid foundation for high-precision processing.

Core components: dual guarantee of quality and technology

In the selection of core components, Hongjia CNC insists on using top brands in the industry, such as C3-level ball screws from PMI, HIWIN or THK, and rolling guides from the same brand, to ensure high-precision movement of the machine tool in the three-axis direction. Especially for the Z axis, the V6/V7 series is equipped with ball screws and roller guides from Rexroth, Hiwin, Yintai or THK, which further enhances the load-bearing capacity and stability of the machine. All three axes use P4-grade bearings, combined with Speedcn brand precision couplings, which effectively reduce transmission errors and improve processing efficiency.

Efficient processing: Stable performance and protection are equally important

In order to ensure stable and efficient cutting performance, Hongjia CNC's Vertical Machining Center is equipped with Speedcn short-nose spindles. Its design not only optimizes the transmission of cutting force, but also effectively prevents the damage of the spindle to the debris generated during the cutting process through the protective cover, extending the service life of the equipment. In addition, the machine's built-in fully automatic tool changing system greatly improves processing efficiency, and the optional nitrogen balancing device further balances the dynamic load in the spindle movement, so that it can maintain excellent performance in high-load, high-precision processing tasks.

Flexible configuration: meet diverse processing needs

In order to meet the specific needs of different customers, Hongjia CNC's Vertical Machining Center provides a wealth of optional configurations. For example, customers can choose the BBT40-Ф120-15000rpm direct type Speedcn long nose spindle, or the BBT40-Ф155-12000rpm direct type Speedcn short nose spindle to meet the requirements of different materials and processing difficulties. At the same time, the Yitai brand 24T tool changer, with its fast and accurate characteristics, provides another strong support for improving processing efficiency. For applications that require higher precision and stability, you can also choose a nitrogen counterweight system and upgrade to a central water cooling system (divided into direct types with and without rotary joints). These configurations further enhance the performance of the machine tool in high-precision, high-load processing environments.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى