Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

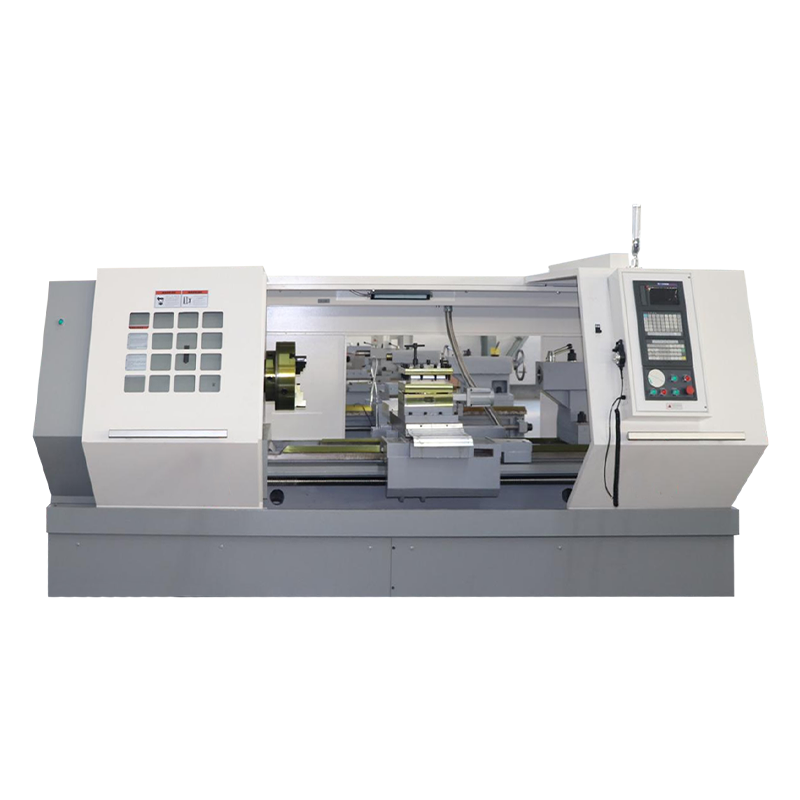

CK6163 ordinary horizontal lathe

Summarize

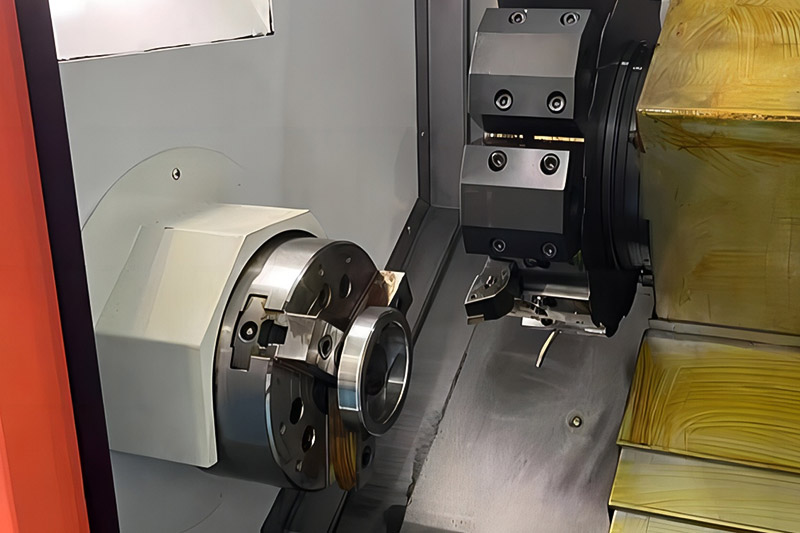

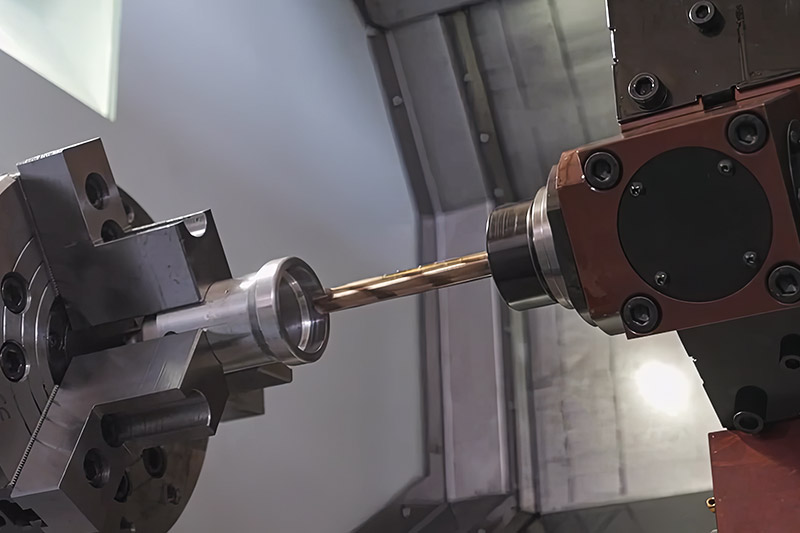

CK6163 series ordinary horizontal lathe is suitable for processing all kinds of short shaft and disk parts, and can automatically complete the inner and outer round surface, conical surface, arc surface, end surface and other rotating surface processing and turning thread and other functions. It is a very versatile horizontal lathe, which is widely used for batch processing of various shaft and disk parts. This series of machine tools has good dynamic performance, accurate motion precision control, stable machining accuracy, and good consistency.

Production Information

The main technical parameters and accuracy of the machine tool:

① Main technical parameters of machine tools:

| item | unit | specification | remark | |

| Maximum turning diameter on the bed | mm | 630 | ||

| Maximum cutting length | mm | 850/1350/1850 | Standard configuration | |

| Maximum cutting diameter | mm | 630 | Standard configuration | |

| Maximum turning diameter on a skateboard | mm | 450 | Standard configuration | |

| Width of the guide surface | mm | 550 | ||

| Spindle end type and code | A11 | |||

| Main shaft hole diameter | mm | 105/130 | ||

| Maximum pass bar diameter | mm | 91/116 | ||

| headstock | Spindle speed range / The maximum output torque of the spindle |

r/min/Nm | 30-84;300-835;53-150;125-350 | Manual transmission |

| Main motor power | kW | 11 | ||

| chuck | Chuck diameter | mm | 400 Manual operation | Hydraulic matching |

| X-axis fast-moving speed | m/min | 4 | ||

| Z-axis fast-moving speed | m/min | 8 | ||

| X-axis travel | mm | 370 | Standard configuration | |

| Z-axis travel | mm | 1000/1500/2000 | Standard configuration | |

| item | unit | specification | remark | |

| Tailstock sleeve diameter/stroke | mm | 100/250 | ||

| Tailstock spindle taper | Mohs | 6# | ||

| Standard tool holder form | Lap Si | |||

| Tool size | Cylindrical cutter | mm | 32×32 | |

| Boring bar diameter | mm | Ф32 | ||

| Total machine weight approx | kg | 4300/4500/5000 | ||

| Machine tool profile | Length × width × height | mm | 3300/3800/4300×1800×1850 | |

② Machine accuracy:

The accuracy of the machine implements GB/T 25659.1-2010 "Simple CNC horizontal lathe Part 1: Accuracy Test".

| Check the items | National Standard | |

| Machining accuracy | IT7 | |

| Machining the roundness of the workpiece | 0.005 | |

| Machining workpiece cylindricity | 0.01/300 | |

| Machining workpiece flatness | 0.015/Ф300 | |

| Machining surface roughness | Ra1.6μm | |

| Positioning accuracy | X-axis | 0.01 |

| z-axis | 0.015 | |

| repeat Positioning accuracy | X-axis | 0.01 |

| z-axis | 0.015 | |

Recommended Products

Keep in Touch

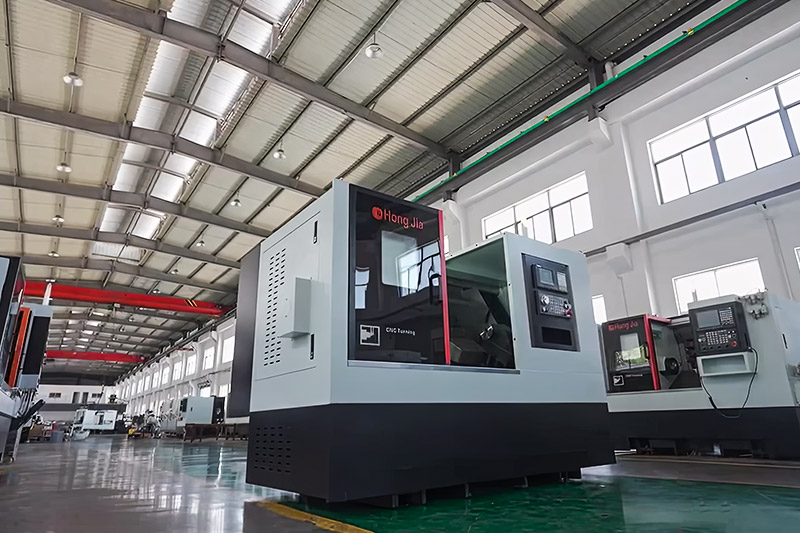

Ningbo Hongjia CNC Technology Co., Ltd.

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China CK6163 ordinary horizontal lathe supplier and custom CK6163 ordinary horizontal lathe company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE -

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE

Industry knowledge

CK6163 Ordinary Horizontal Lathe: An Efficient Model of Precision Manufacturing

Ningbo Hongjia CNC Technology Co., Ltd is a comprehensive high-tech enterprise integrating R&D, production and sales. Since its establishment, the company has always adhered to the core concept of "technological innovation, quality first", constantly breaking through technical barriers, and promoting China's CNC machine tool industry to a higher level. In the development process of CK6163 Ordinary Horizontal Lathe, Hongjia CNC brought together a research and development team composed of senior engineers and technical experts. Through accurate grasp of market demand and deep insight into technological trends, it successfully created this lathe product that combines efficiency, stability and economy.

CK6163 Ordinary Horizontal Lathe, as Hongjia CNC's masterpiece, not only inherits the reliability of traditional horizontal lathes, but also incorporates the essence of modern CNC technology, making it an ideal choice for processing short shaft and disc parts. The lathe can automatically complete the processing of various rotating surfaces such as inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end surfaces, as well as complex processes such as thread turning, showing extremely high versatility and flexibility. Whether it is automotive parts, mechanical accessories or precision parts in the aerospace field, CK6163 can meet diverse production needs with its excellent processing capabilities.

In terms of performance, CK6163 Ordinary Horizontal Lathe shows extraordinary dynamic characteristics and motion precision control capabilities. Its drive system adopts advanced servo motors, combined with precise transmission mechanisms, to ensure stability and accuracy during the processing process. At the same time, the lathe's bed, guide rails and other key components have been strictly selected and precision processed, which effectively improves the rigidity and stability of the overall structure, thereby ensuring high precision and consistency during long-term processing. In addition, CK6163 is also equipped with an intelligent control system, users can easily set processing parameters through an intuitive interface, monitor the processing status in real time, and greatly improve production efficiency and management level.

Thanks to its excellent performance and design, CK6163 Ordinary Horizontal Lathe has been widely used in various manufacturing industries. In the automotive parts manufacturing industry, it can efficiently complete the precision cutting of key parts such as wheels and shafts; in the field of mechanical manufacturing, it is an ideal tool for processing various transmission shafts and gear shafts; in addition, in high-end fields such as aerospace and precision instrument manufacturing, CK6163 also demonstrates its irreplaceable value, providing high-precision and high-efficiency processing solutions for these industries.

Ningbo Hongjia CNC Technology Co., Ltd is well aware that high-quality products are inseparable from a perfect service system. Therefore, the company not only provides high-quality CK6163 Ordinary Horizontal Lathe, but also establishes a comprehensive after-sales service network to ensure that customers can get timely and professional answers and help for any problems encountered during use. From pre-sales consultation, installation and commissioning to after-sales maintenance, Hongjia CNC has always been customer-centric and is committed to providing customers with a one-stop, full-cycle service experience.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى