Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

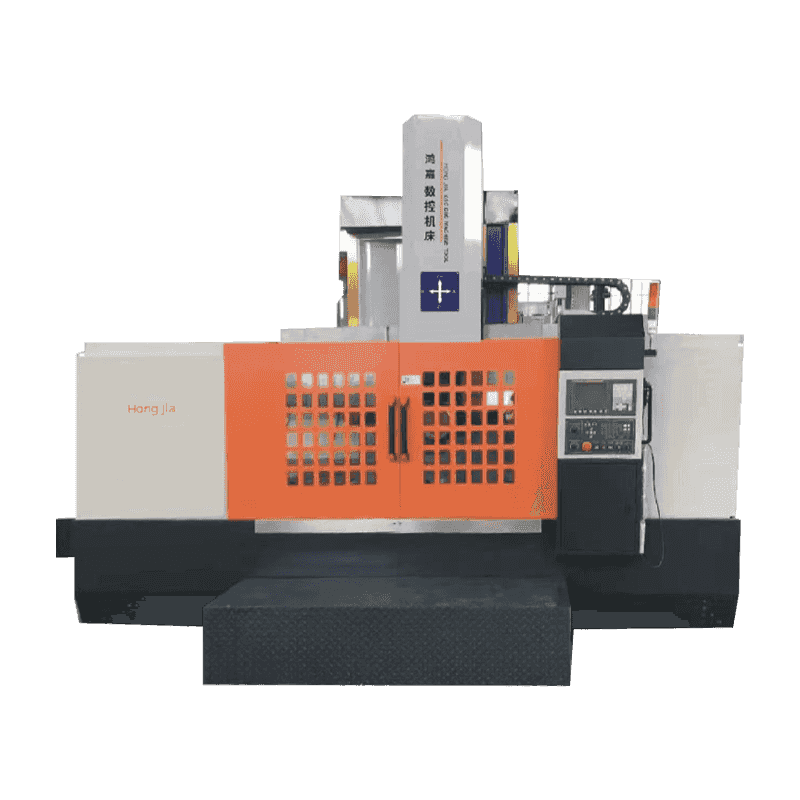

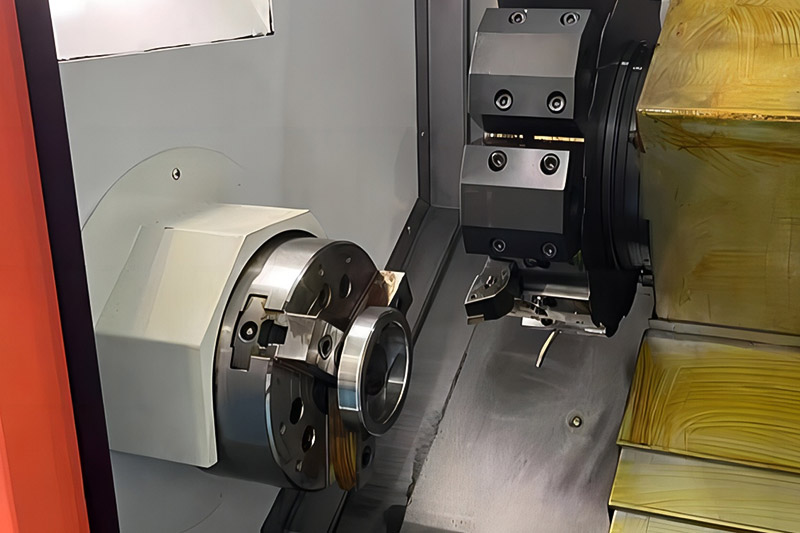

CK-5116B Siemens 808D CNC single-column vertical lathe

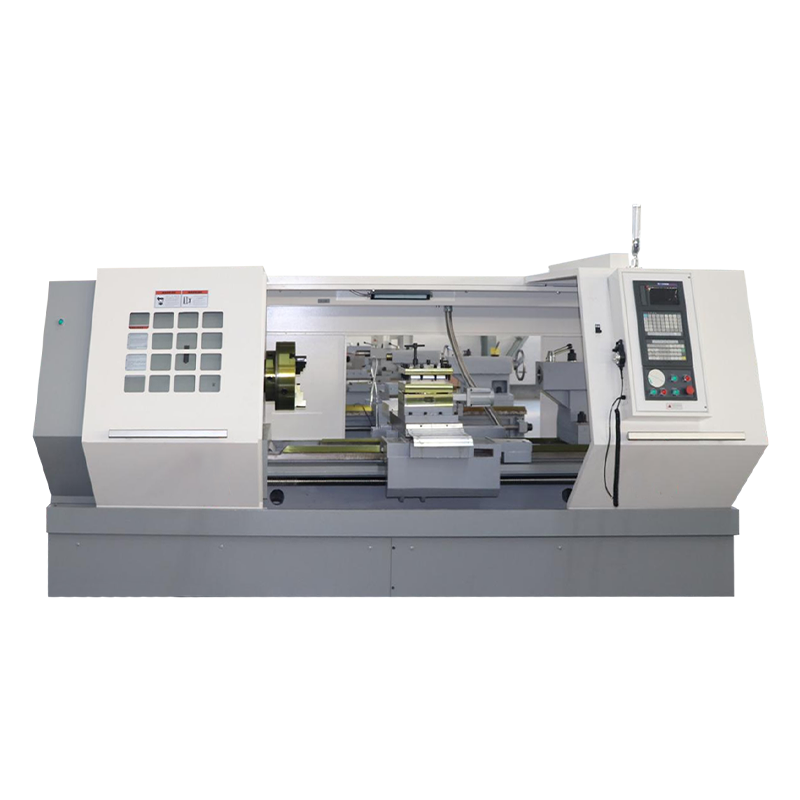

Numerical control lathe

CK51 series CNC single-column vertical lathe is a high-tech mechatronic product that our company absorbs the contemporary advanced design and manufacturing technology, adopts CAD optimization design method, implements enterprise precision standard, configures domestic and foreign advanced functional components, and realizes strong cutting force in structural performance, super-heavy load on the table, high dynamic and static rigidity of the machine tool, safety and reliability of all movements, long service life and high processing efficiency. The machine is a high-tech electromechanical integrated product.Equipped with advanced Siemens 808D CNC system, it can achieve precise control. The machine tool includes a 320 four-station electric cutting table, a four-speed continuously variable transmission and a 30KW servo main motor, ensuring stable power and efficient processing capabilities under different process conditions. Its semi-enclosed protection structure, beam protection, automatic chip removal and water cooling system effectively improve safety, cleanliness of the processing environment and durability of the equipment.

Production Information

Machine configuration

1. Siemens 808D CNC system;

2.320 four-station electric cutting table;

3. Four-speed continuously variable transmission, main motor 30KW servo motor;

4. Semi-enclosed protection, crossbeam protection, chip removal, water cooling;

5. Equipped with a self-centering hydraulic chuck with a diameter of 1400mm;

6. The machine tool has no threading function and does not come with a spindle encoder;

7. The workbench base is supported by rolling guide rails.

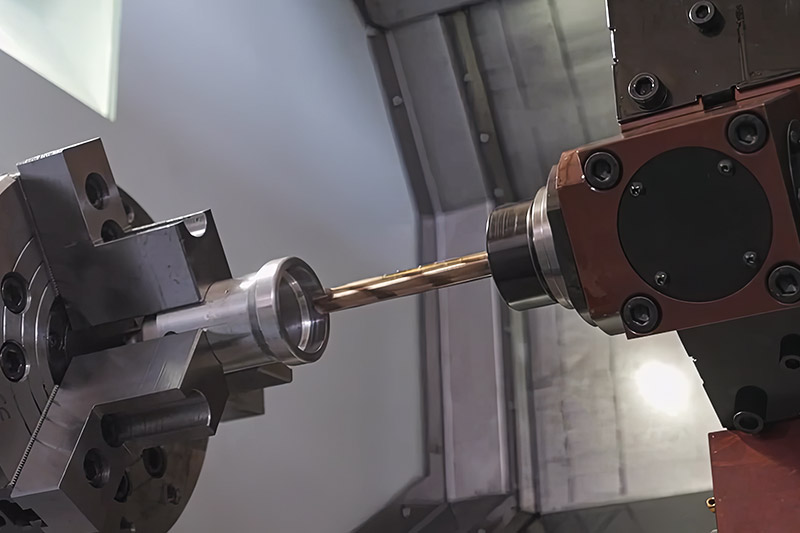

Machine tool usage

This machine tool is suitable for high-speed steel cutting tools, hard alloy cutting tools, and various high-performance cutting tools to process black metal, non-ferrous metal, and some non-metallic material workpieces. It can complete rough and precision turning of inner and outer cylindrical surfaces, inner and outer conical surfaces, flat surfaces, rotary surfaces, and grooves on the machine tool.

Technical Parameter

| Item | Unit | CK5116B |

| Cutting tool post the biggest diameter | mm | 1600 |

| Hydraulic chuck diameter | mm | 1400 |

| Maximum height of the workpiece | mm | 1200 |

| Maximum weight of workpiece | t | 5 |

| Workbench speed range | r/min | 1-160 |

| Bench speed level | Four-speed stepless | |

| Maximum torque of workbench | Kn/m | 30 |

| Number of feed stages for the tool holder | Wlevel | Stepless |

| Maximum cutting force of the upright tool holder | KN | 25 |

| Horizontal stroke | mm | 950 |

| Vertical stroke | mm | 800 |

| Cross beam travel | mm | 850 |

| Range of feed rate for tool holder | mm/min | 0.1-500 |

| Rapid movement speed of the tool holder | mm/min | 2000 |

| Beam lifting speed | mm/min | 440 |

| Knife bar cross-sectional dimensions (length x width) | mm | 30x40 |

| Main motor power | kW | 30 |

| System configuration | Siemens 808D | |

| CNC coordinate axis | X. Z-axis linkage | |

| Machine weight (approximately) | t | 14.5 |

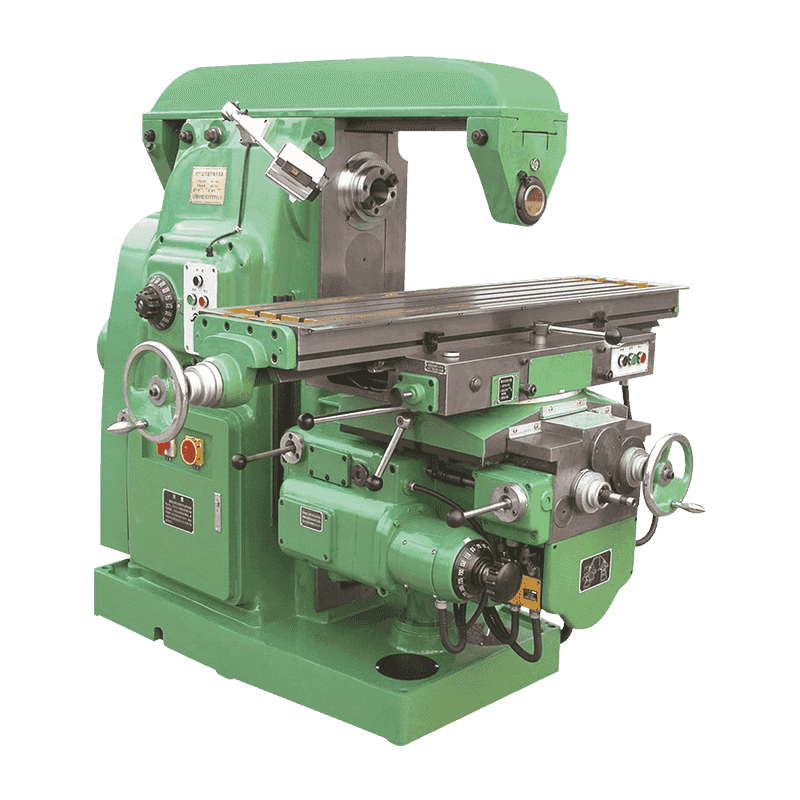

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

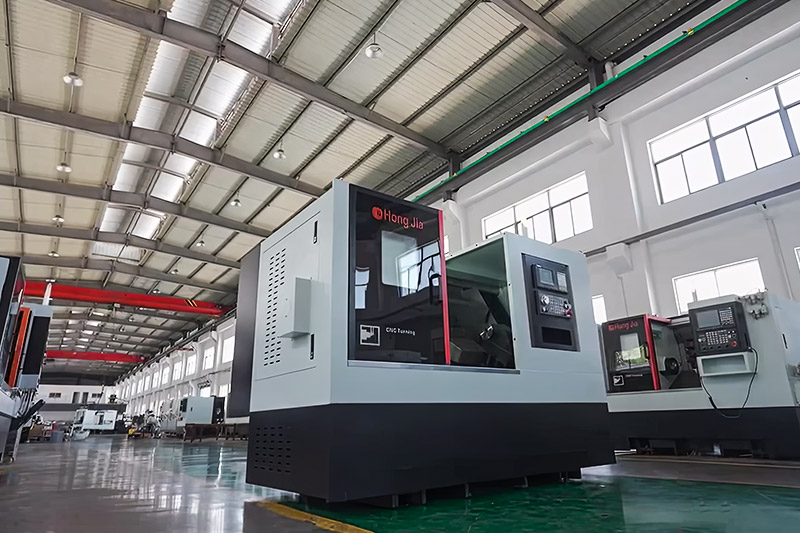

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China CK-5116B Siemens 808D CNC single-column vertical lathe supplier and custom CK-5116B Siemens 808D CNC single-column vertical lathe company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE -

In the field of mechanical processing, cutting fluid management and chip handling efficiency are very important product performance indicators. The drawout coolant tank horizontal turning center separates the cutting flu...

READ MORE -

In the field of precision device processing and manufacturing, high-rigidity horizontal turning centers are becoming the core equipment for complex parts processing with their precise control systems and advanced program...

READ MORE

Industry knowledge

Ningbo Hongjia CNC Technology Co., Ltd has been committed to becoming a technology leader in the industry since its establishment. The company has a research and development team composed of senior engineers and technical experts. With strong technical strength and rich industry experience, they continue to explore the boundaries of CNC technology and provide customized advanced CNC solutions for customers in different industries. CK-5116B Siemens 808D CNC Single-Column Vertical Lathe is the concentrated embodiment of Hongjia CNC's technical strength. It not only represents the company's latest achievements in the field of high-end equipment manufacturing, but also a vivid interpretation of the company's concept of "customer-centric, innovation-driven development".

CK-5116B Siemens 808D CNC Single-Column Vertical Lathe, as a high-tech mechatronics product carefully crafted by Hongjia CNC, integrates the culmination of contemporary advanced design and manufacturing technologies. This product uses CAD optimization design methods to ensure the rationality and optimization of the machine tool structure. At the same time, it strictly follows the company's precision manufacturing standards and is equipped with advanced functional components at home and abroad, so that it can achieve strong cutting force, super heavy load capacity of the workbench, and high dynamic and static stiffness of the machine tool in terms of structural performance.

The core of CK-5116B lies in its advanced Siemens 808D CNC system. With its powerful data processing capabilities and high-precision control capabilities, the system ensures that every action of the machine tool during the processing process can achieve extremely high accuracy. Whether it is simple contour processing or complex surface processing, Siemens 808D can handle it with ease, bringing users an unprecedented processing experience. In addition, the system also has a friendly user interface and intuitive operation process, even first-time operators can quickly get started, greatly improving production efficiency and convenience of operation.

In order to further improve processing efficiency and flexibility, the CK-5116B Siemens 808D CNC Single-Column Vertical Lathe is equipped with a 320mm four-station electric turret tool holder. This design not only reduces tool change time, but also greatly expands the processing range. At the same time, the machine's four-speed continuously variable transmission system and 30KW high-power servo main motor ensure that stable and powerful power output can be provided under different process conditions to meet the needs of various materials and complex processing. Whether it is the depth, speed or surface finish of metal cutting, CK-5116B can reach the industry-leading level.

Safety is always the primary consideration for Hongjia CNC to design machine tools. The semi-enclosed protective structure and beam protection design adopted by the CK-5116B Siemens 808D CNC Single-Column Vertical Lathe effectively isolate the splashes during the processing process and ensure the safety of the operator. At the same time, the addition of the automatic chip removal system and water cooling system not only improves the cleanliness of the processing environment, but also effectively extends the service life of the machine tool and reduces maintenance costs. These humanized designs reflect Hongjia CNC's profound understanding and practice of the concept of sustainable development.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى