Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / Products / Horizontal CNC turning and milling series / NC-106D high-efficiency heavy-cutting horizontal turning center

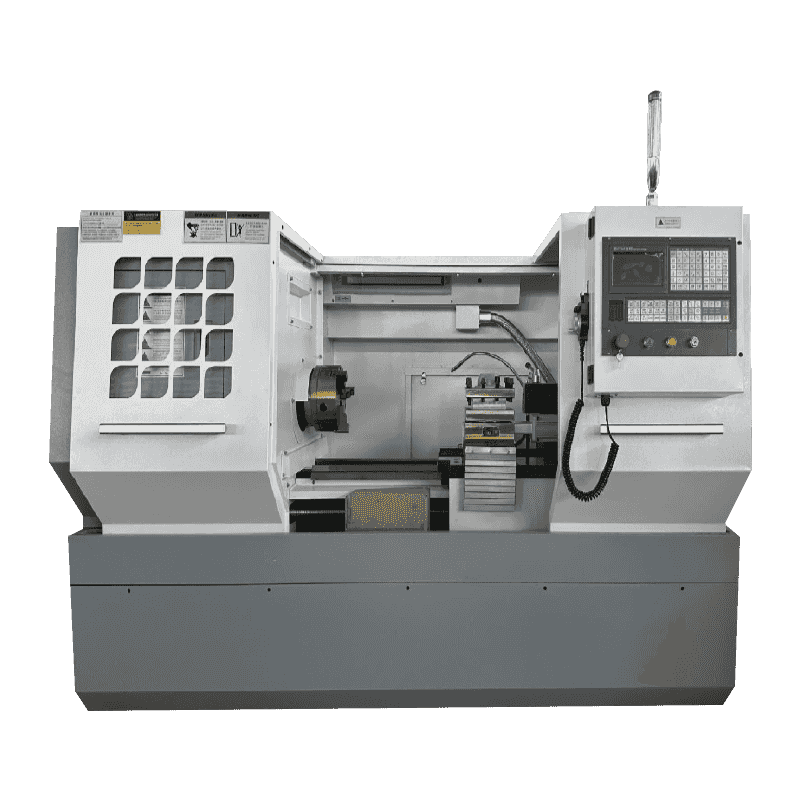

Home / Products / Horizontal CNC turning and milling series / NC-106D high-efficiency heavy-cutting horizontal turning center NC-106D high-efficiency heavy-cutting horizontal turning center

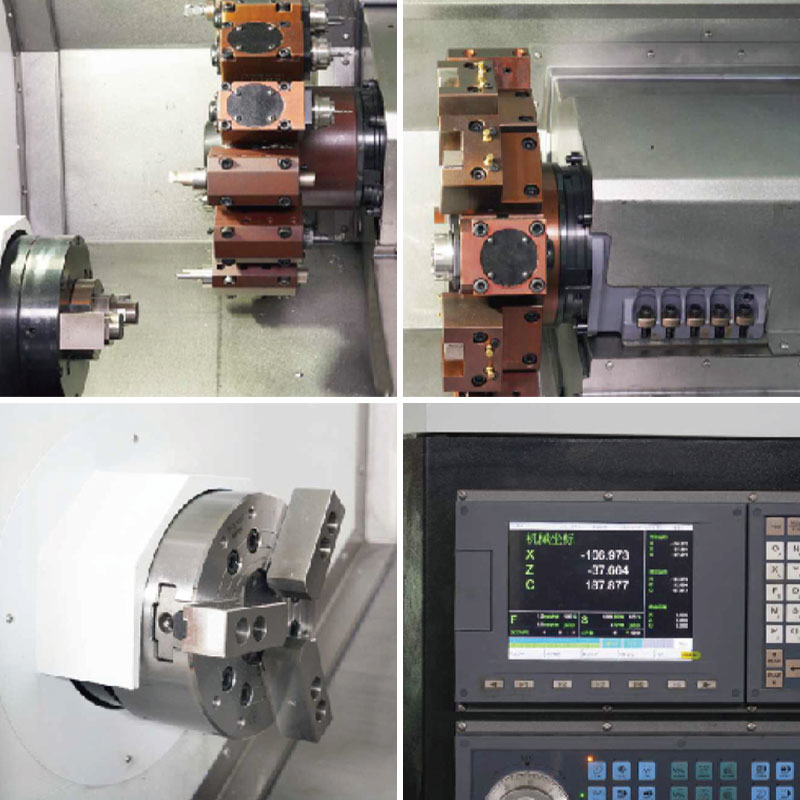

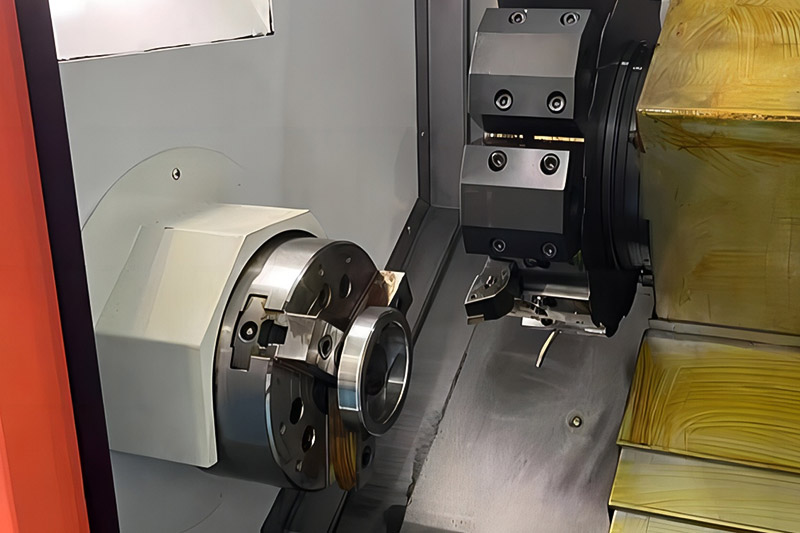

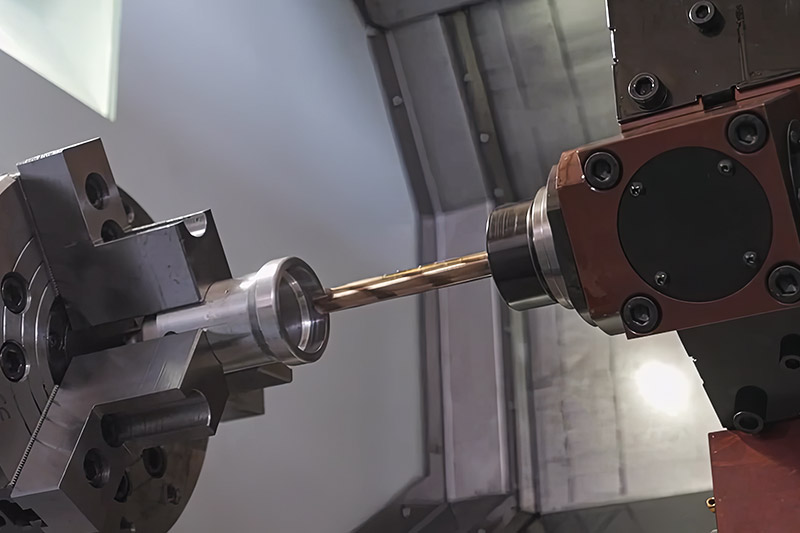

High-efficiency heavy-cutting horizontal turning center is a high-performance machine tool designed for heavy-duty processing and high-precision manufacturing. It has a high-rigidity basic structure and can achieve stable heavy-load cutting. The equipment adopts an advanced drive system and a built-in high-speed precision spindle, equipped with a multi-station power turret, and supports a variety of processing processes such as turning, drilling and boring. Its efficient cooling and chip removal system ensures cleanliness and stability for long-term operation, suitable for high-intensity production needs, while providing excellent processing accuracy and production efficiency, making it the only choice in the heavy industry field.

Production Information

Processing Capability

1. Lathe, drilling, and boring can be carried out

2. High rigidity basic structure. to achieve heavy-cutting

3. Excellent cutting ability and stable processing accuracy to achieve high production

4. The draw-out coolant tank is used for easy cleaning and cutting

5. Standard tank capacity: 100L

Machine tool basic configuration

1. New generation SYTEC/22TA

2. New generation drive motor and spindle drive

3. Built-in high-speed precision motorized spindle is standard

4. Taiwan or Japan wire rail and screw

5. Separate water tank

6. Chip removal machine

7. Oil pressure three claws

8. Power tower 12 stations

Technical Parameter

| Item | NC-106D |

| Max. machining diameter | Φ280mm |

| Max. working length | 300mm |

| Max. turning diameter | 500mm |

| Spindle chuck dimensions | 6/8inch |

| Max. spindle speed | 5000min-1 |

| Spindle end shape | A2-5 |

| Through the aperture of the spindle | Φ56mm |

| The inner diameter of the spindle expansion tube | Φ45mm |

| The inner diameter of the main shaft bearing | Φ90mm |

| Spindle power | 11KW |

| Rated spindle torque | 35N.m |

| Max. spindle torque | 70N.m |

| Number of turret surfaces | 12 |

| Handle of outer diameter tool | 20X20 |

| Bit seat bore | Φ25 |

| Turret power head model | BMT40/ER20 |

| Maximum speed of turret power head | 4000mm-1 |

| Cutter tower power head motor power | 2.4kw |

| Turret power head torque | 7.7N.m |

| Feed axis Z/X direction travel | Z: 370mm X:185mm |

| Feed shaft Z/X motor power | 1.7KW |

| Fast shift speed Z/X | Z:20m/min X:20m/min |

| Fast shift speed A | A:20m/min |

| Power supply capacity | 20KVA |

| Overall dimensions of the machine (LxWxH) | 2040×1560×1715mm(Without chip conveyor) Chip removal machine not included |

| Machine weight | 3500kg |

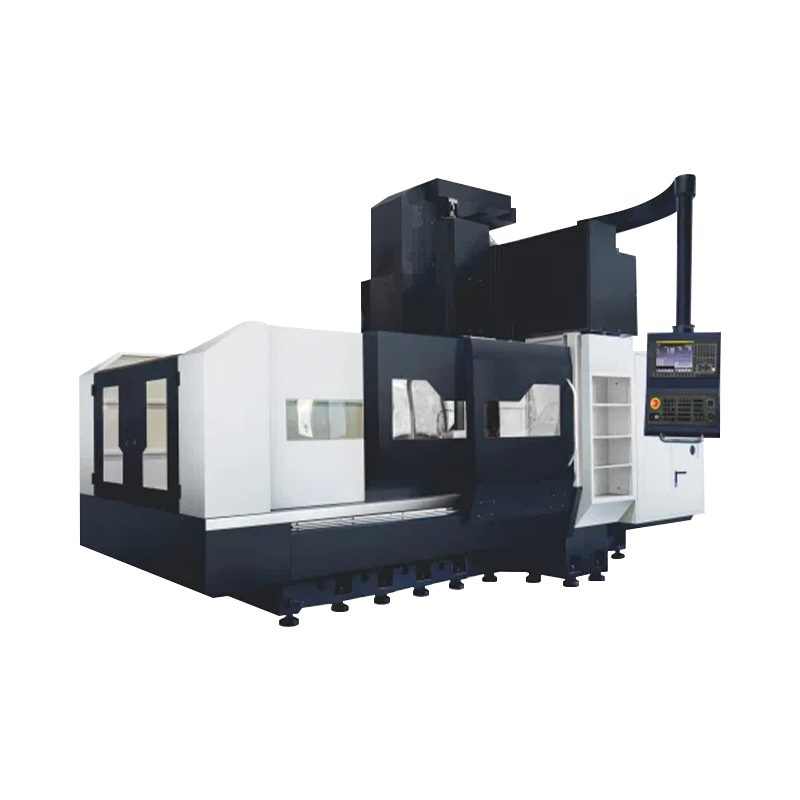

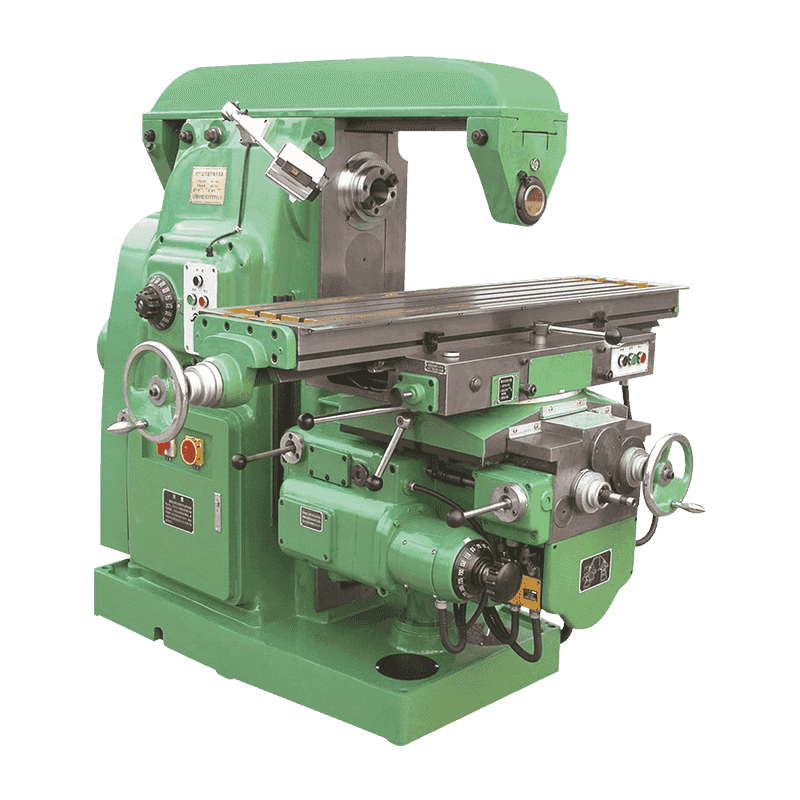

Recommended Products

Keep in Touch

Ningbo Hongjia CNC Technology Co., Ltd.

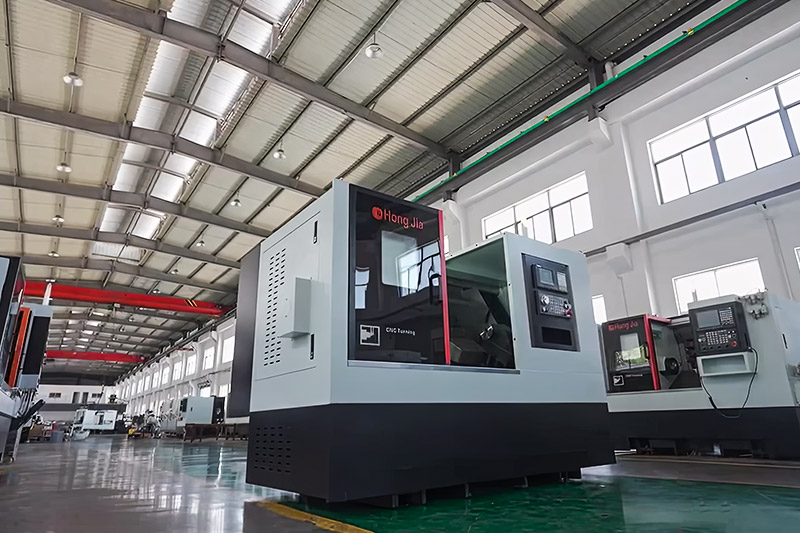

Ningbo Hongjia CNC Technology Co., Ltd. started in 2006 and was established in 2018. It is located in Qianwan New District, Ningbo City, Zhejiang Province, south wing of China Yangtze River Delta Economic Zone. It is an enterprise specializing in the research, development, production and sales of CNC metal cutting equipment. As a China NC-106D high-efficiency heavy-cutting horizontal turning center supplier and custom NC-106D high-efficiency heavy-cutting horizontal turning center company, With strong technical strength and rich industry experience, Hongjia CNC is committed to providing customers with advanced CNC solutions to meet the needs of customers in different industries.

What’s News

-

In the wave of industrial manufacturing, low-noise CNC horizontal lathes not only continue the rigorous process of traditional mechanical processing, but also incorporate innovative materials and intelligent design, whil...

READ MORE -

As the core system of precision machining equipment, the standardization of post-use cleaning and post-maintenance of the Drawout Coolant Tank Horizontal Turning Center directly affects the machining accuracy, tool life ...

READ MORE -

1. Reduce the risk of cutting fluid leakage and contaminationThe traditional integrated coolant system is prone to leakage due to long-term vibration and seal aging, causing the cutting fluid to penetrate into the machin...

READ MORE

Industry knowledge

Why is the High-Efficiency Heavy-Cutting Horizontal Turning Center an ideal choice for heavy industrial applications?

Ningbo Hongjia CNC Technology Co., Ltd: Professional CNC Equipment Manufacturer

Ningbo Hongjia CNC Technology Co., Ltd focuses on the research and development, production and sales of CNC metal cutting equipment, and is committed to providing advanced CNC solutions for customers in various industries. As a supplier and custom manufacturer of NC-106D High-Efficiency Heavy-Cutting Horizontal Turning Center, Hongjia CNC relies on its strong technical strength and rich industry experience to create high-performance, high-precision machine tool equipment to meet customers' diverse processing needs.

The High-Efficiency Heavy-Cutting Horizontal Turning Center is a high-performance machine tool designed for heavy-duty processing and high-precision manufacturing. With its high-rigidity basic structure, the equipment can achieve stable heavy-duty cutting while having excellent processing accuracy and production efficiency, occupying an irreplaceable position in the heavy industry field.

Excellent processing capabilities to meet various process requirements

The High-Efficiency Heavy-Cutting Horizontal Turning Center supports a variety of processing technologies such as turning, drilling and boring, and can meet the efficient processing needs of complex parts. Its high-rigidity structure ensures stability during heavy cutting, effectively reduces vibration, and improves processing accuracy, making it an ideal equipment for high-intensity production environments.

High-rigidity structure for stable heavy cutting

The equipment adopts a high-rigidity basic structure design, which can withstand high-load cutting forces and ensure the stability and accuracy of the processing process. Combined with high-quality linear rails and lead screws from Taiwan or Japan, the machine tool further improves the stability and service life of the processing, enabling it to operate stably for a long time.

High-performance drive system and high-speed spindle to improve production efficiency

This machine tool adopts a new generation of SYTEC/22TA control system and is equipped with advanced drive motors and spindle drive systems to achieve more accurate processing control. The built-in high-speed precision electric spindle not only improves the processing speed, but also ensures processing accuracy, meeting the dual needs of high efficiency and high precision in the high-end manufacturing industry.

Multi-station power turret improves processing flexibility

The equipment is equipped with a 12-station power turret, which supports a variety of tool configurations, enabling it to efficiently complete the processing of different processes, reduce tool change time, and improve overall production efficiency. The high stability of the power turret also ensures reliability during long-term continuous processing.

Efficient cooling and chip removal system to ensure long-term stable operation

The machine tool is equipped with an independent water tank and an advanced chip conveyor, which can quickly remove chips, reduce heat accumulation during the cutting process, and improve processing stability. The drawer-type coolant tank is designed for easy cleaning and maintenance, and the standard coolant capacity reaches 100L, which is suitable for long-term high-intensity processing needs.

Meets the high-intensity production needs of heavy industry

As an efficient processing equipment specially designed for heavy industry, the High-Efficiency Heavy-Cutting Horizontal Turning Center is widely used in automobile manufacturing, aerospace, shipbuilding, energy equipment and other industries with its excellent cutting ability, stable processing accuracy and efficient production capacity, and can cope with various high-intensity production challenges.

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى