Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / News / Industry News / What Are the Benefits of the Spindle High-Pressure Center Out Function in the High Speed Drilling Center?

Home / News / Industry News / What Are the Benefits of the Spindle High-Pressure Center Out Function in the High Speed Drilling Center? What Are the Benefits of the Spindle High-Pressure Center Out Function in the High Speed Drilling Center?

2025.03.07

2025.03.07

Industry News

Industry News

Definition and Principle of the Spindle High-Pressure Center Out Function

The spindle high-pressure center out function refers to the integration of a high-pressure coolant channel inside the spindle of the High Speed Drilling Center, and the coolant is directly sprayed to the contact area between the tool and the workpiece through the spindle center.

1. Efficient cooling and lubrication

During high-speed machining, the friction between the tool and the workpiece will generate a lot of heat, which will increase tool wear and even affect machining accuracy. The high-pressure center out function quickly reduces the temperature of the cutting area by spraying high-pressure coolant, prolongs the tool life, and reduces the impact of thermal deformation on machining accuracy.

2. Chip removal ability

During high-speed machining, the accumulation of chips will seriously affect the machining quality and even damage the tool. The high-pressure center out function flushes the chips away from the machining area through high-pressure coolant to ensure the continuity and stability of the machining process.

Core advantages of the spindle high-pressure center out function

1. Improve machining efficiency

The high-pressure center out function can significantly increase machining speed, especially in deep hole drilling and hard material machining. In the High Speed Drilling Center, this function is combined with the high-precision direct-connected spindle to achieve a "drill-to-the-bottom" processing method, that is, drilling and tapping are completed in one operation.

2. Improve processing accuracy

In high-speed processing, thermal deformation and chip accumulation are the main factors affecting processing accuracy. The high-pressure center water outlet function effectively reduces the occurrence of these problems through cooling and chip removal. Supported by the multi-layer cross-beam structure and large-span design, the High Speed Drilling Center can maintain high-precision processing at high speeds, and the high-pressure center water outlet function further ensures the stability of processing quality.

3. Extend tool life

Tool wear directly affects processing costs and quality. The high-pressure center water outlet function significantly reduces tool wear and extends tool life through cooling and lubrication. This is of great economic significance for companies that require long-term continuous processing.

Value in practical applications

1. Efficient solution for deep hole drilling

In deep hole drilling, it is difficult for coolant to reach the cutting area, resulting in low processing efficiency and short tool life. The high-pressure center water outlet function solves this problem by delivering coolant directly to the cutting area. For example, in the High Speed Drilling Center, this function can efficiently complete deep hole drilling tasks while ensuring processing quality.

2. Ideal choice for hard material processing

Hard material processing places higher demands on tools and machine tools. The high-pressure center water outlet function significantly improves the processing efficiency and quality of hard materials through cooling and chip removal. In the High Speed Drilling Center, this function is combined with the fast tool change function to efficiently complete the processing tasks of complex workpieces.

3. Reduce production costs

The high-pressure center water outlet function saves production costs for enterprises by improving processing efficiency, extending tool life and reducing equipment maintenance. In the High Speed Drilling Center, this function is combined with the spindle fast start and stop function and the slide synchronous displacement function to significantly improve production efficiency and reduce the processing cost per unit product.

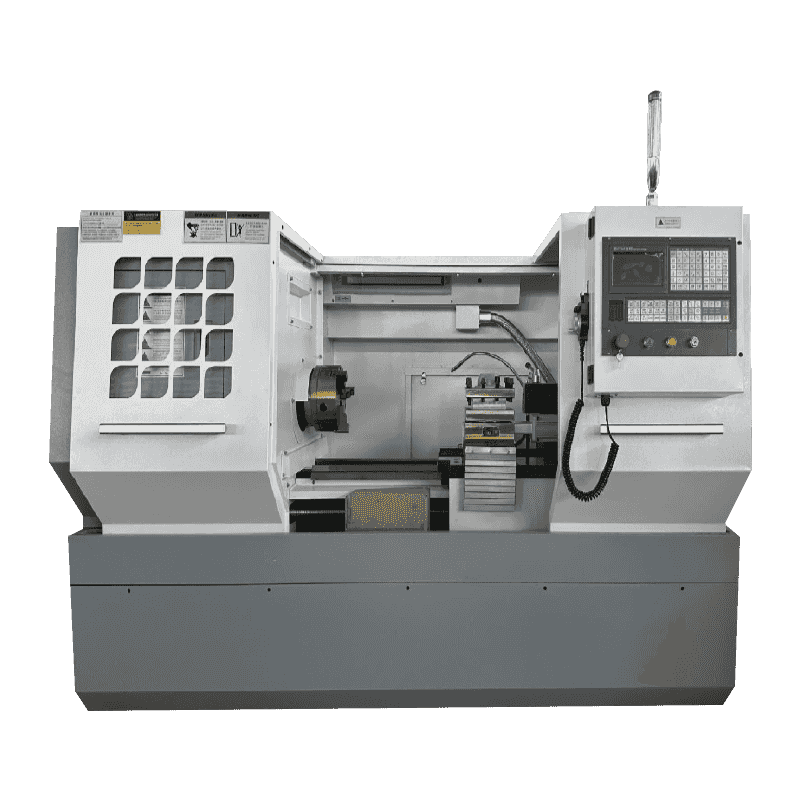

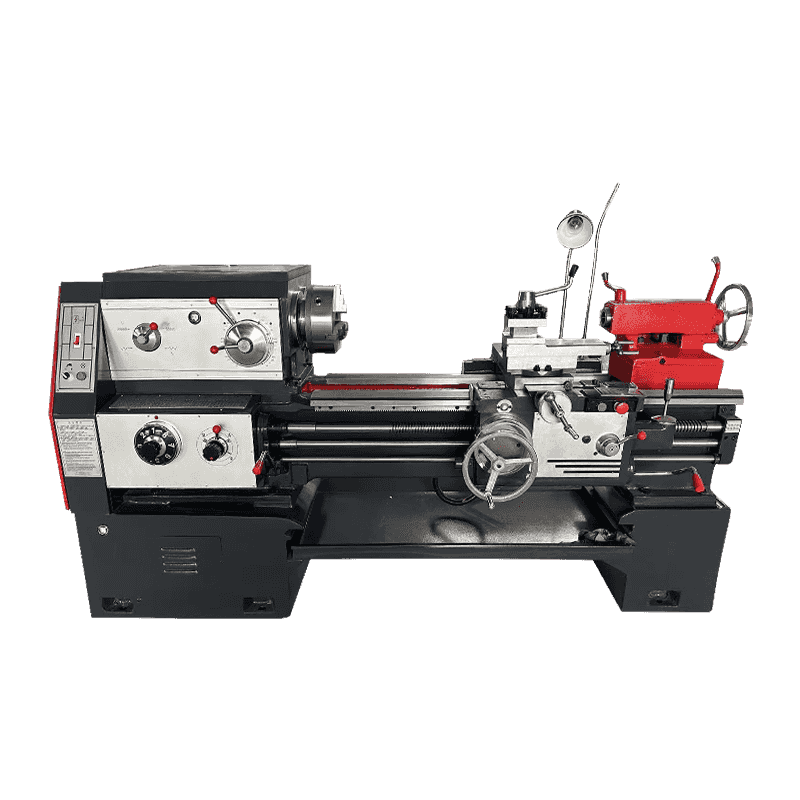

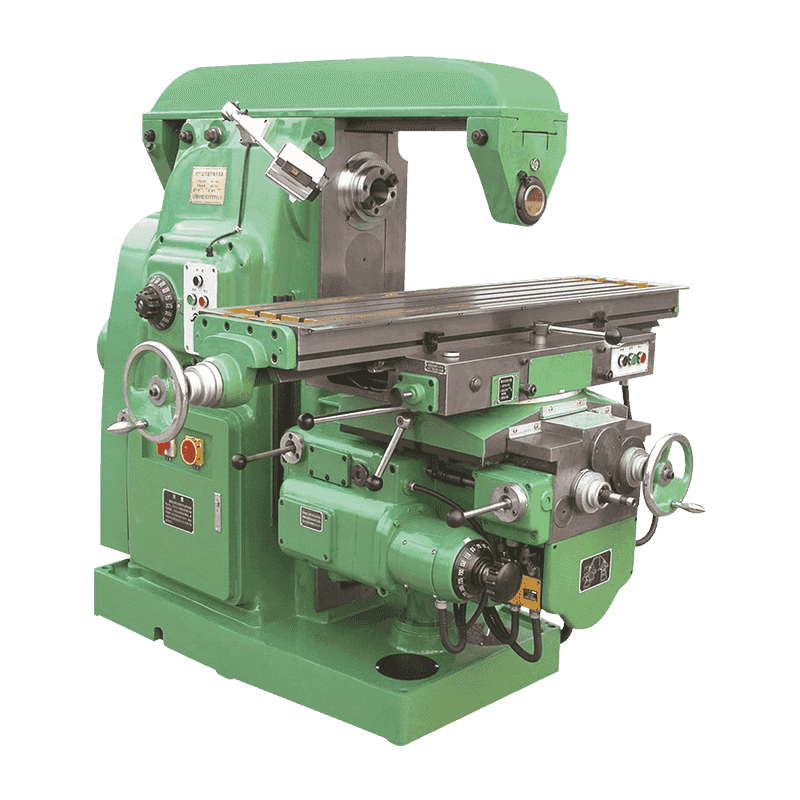

Recommended Products

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى