Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / News / Industry News / Why Is the Large Span Design of the High Speed Drilling Center Ideal for High-Speed Machining?

Home / News / Industry News / Why Is the Large Span Design of the High Speed Drilling Center Ideal for High-Speed Machining? Why Is the Large Span Design of the High Speed Drilling Center Ideal for High-Speed Machining?

2025.03.07

2025.03.07

Industry News

Industry News

Definition and Features of Large Span Design

Large span design refers to the fact that the main structural components of the machine tool have a large span in the horizontal or vertical direction. This design can effectively disperse the vibration and stress generated during the processing, thereby improving the overall rigidity of the machine tool. In the High Speed Drilling Center, the large span design is usually combined with a multi-layer cross beam structure to further enhance the stability and anti-deformation ability of the machine tool.

1. Improve rigidity and reduce vibration

During high-speed processing, the machine tool needs to withstand the huge impact force brought by the high-speed rotating spindle and tool. If the machine tool is not rigid enough, it is easy to vibrate, which affects the processing accuracy and surface quality. The large span design significantly improves the rigidity of the machine tool by increasing the support area of the structure, reduces vibration and deformation, and ensures the stability of the processing process.

2. Optimize load distribution

The large span design can better disperse the load generated during the processing and avoid local stress concentration. This design is particularly suitable for high-load processing tasks such as deep hole drilling and hard material processing. Combined with Japanese precision ball guides, the machine tool can maintain low starting torque and efficient power transmission while bearing high loads.

Advantages of large-span design in high-speed machining

1. High-precision guarantee for high-speed machining

The core goal of High Speed Drilling Center is to achieve high-precision machining at high speed. The large-span design provides a solid foundation for high-precision machining by enhancing the rigidity of the machine tool. The large-span design ensures the stability of the spindle at high speed, thereby achieving efficient machining of "drilling to the bottom".

2. Improve machining efficiency

The large-span design not only improves the rigidity of the machine tool, but also optimizes the overall layout of the machine tool. For example, the synchronous displacement function of the spindle and the carriage can complete the machining program quickly and accurately with the support of the large-span design, significantly reducing the machining cycle time. In addition, the fast tool change function also benefits from the large-span design, further improving production efficiency.

3. Adapt to diverse machining needs

The large-span design enables High Speed Drilling Center to adapt to a wider range of machining tasks. Whether it is machining large workpieces or cutting complex curved surfaces, the long-span design can provide sufficient support and stability.

Value in practical applications

In enterprise production, the long-span design of High Speed Drilling Center not only improves machining accuracy and efficiency, but also saves costs for enterprises. For example, by implementing the "one-drill-to-the-bottom" processing method, enterprises can reduce the number of tool changes and processing time, thereby reducing operating costs.

1. Reduce investment costs

The long-span design enables High Speed Drilling Center to complete a variety of processing tasks with higher efficiency, thereby reducing the company's need for multiple devices. This integrated design not only saves equipment procurement costs, but also optimizes the layout of the production line.

2. Increase production

By reducing vibration, optimizing load distribution and improving processing efficiency, the long-span design significantly increases the daily output of High Speed Drilling Center. This is of great economic significance for enterprises that need large-scale production.

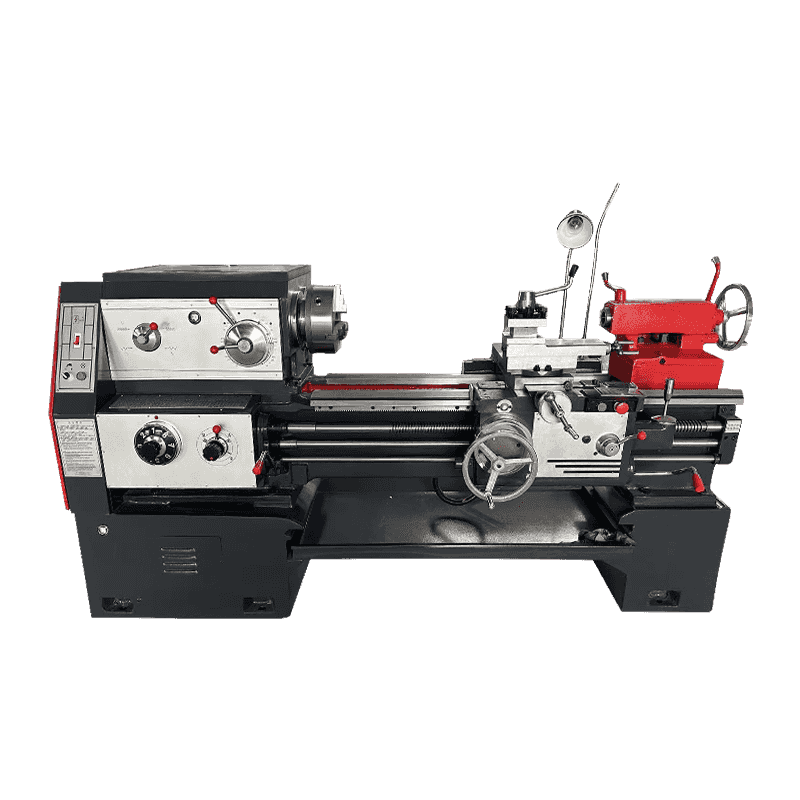

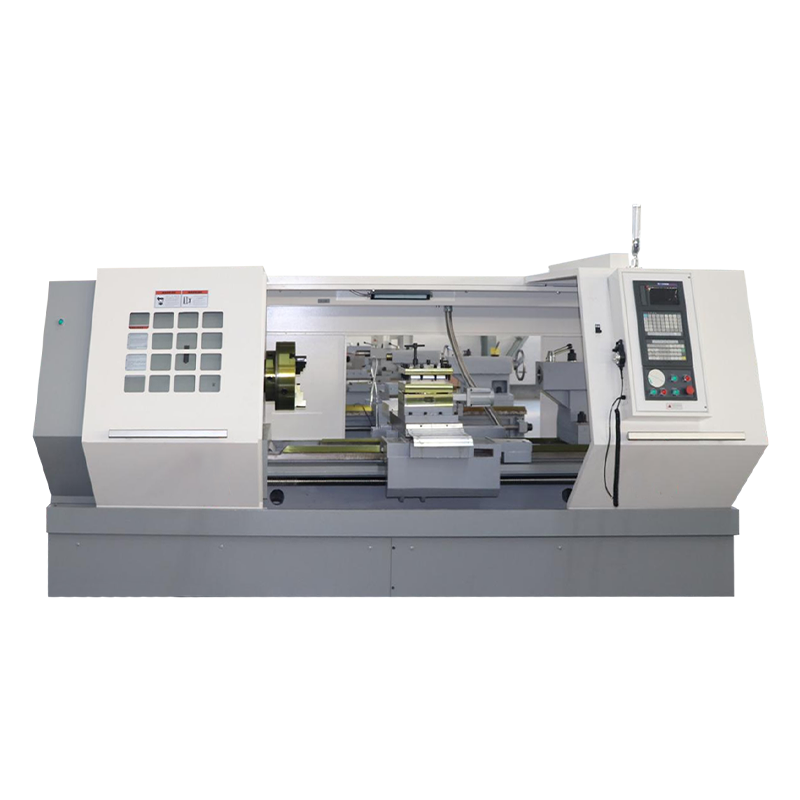

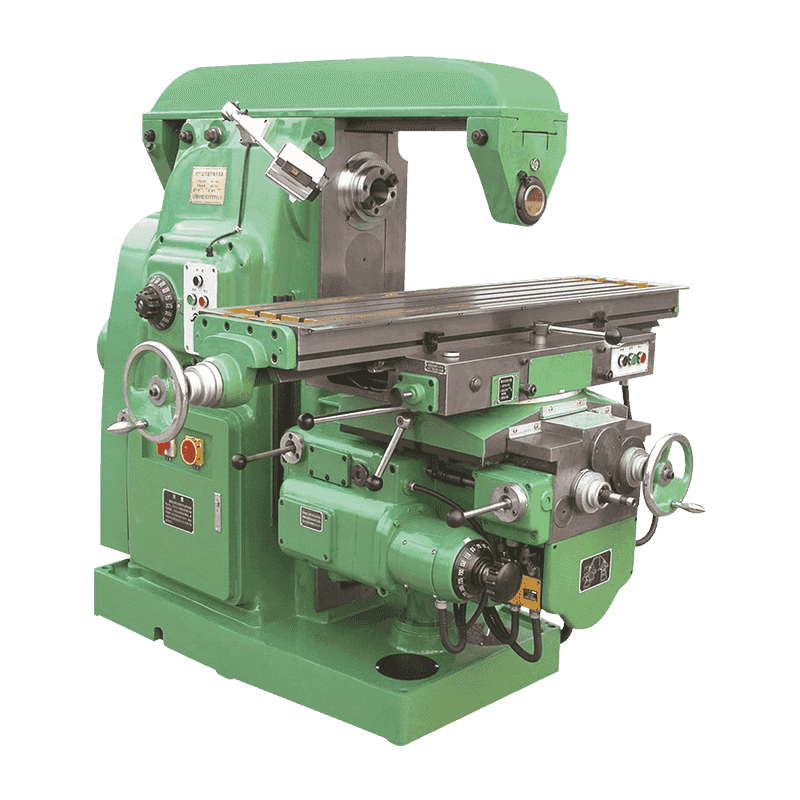

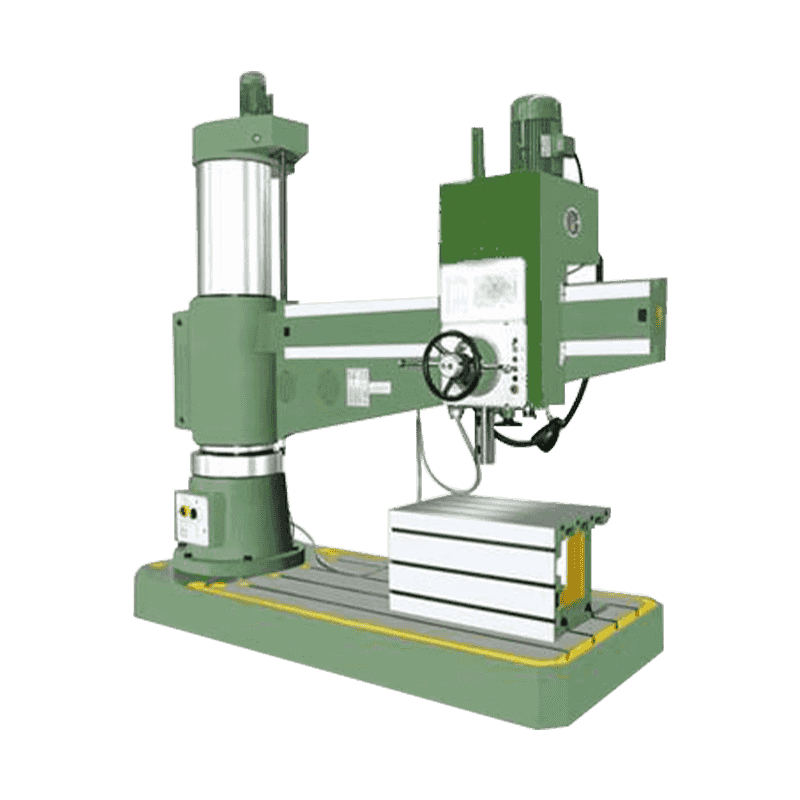

Recommended Products

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى