Don't hesitate to contact when you need us!

Web Menu

Product Search

Exit Menu

Home / News / Industry News / How does a Servo Driven Horizontal Turning Center differ from traditional turning centers?

Home / News / Industry News / How does a Servo Driven Horizontal Turning Center differ from traditional turning centers? How does a Servo Driven Horizontal Turning Center differ from traditional turning centers?

2025.03.07

2025.03.07

Industry News

Industry News

A Servo Driven Horizontal Turning Center represents a significant advancement in machining technology compared to traditional turning centers. The primary difference lies in the use of servo-driven motors for precise control of the machine's movements, which brings about improvements in performance, accuracy, and efficiency. These differences are not only noticeable in the quality of the finished parts but also in the overall productivity and operational flexibility.

Traditional turning centers typically rely on older drive systems such as geared motors or AC motors. While these motors can deliver adequate performance for basic machining tasks, they often struggle with the high precision and flexibility required in modern manufacturing. Traditional machines generally provide basic control over the cutting tool's motion and may require manual adjustments or slower feed rates to achieve the desired outcomes. In contrast, a Servo Driven Horizontal Turning Center uses high-performance servo motors, which offer far superior control over the machine’s axes and spindles. These servo motors can adjust the speed, position, and torque instantly, allowing for dynamic and precise movement without lag or loss of power.

One of the key advantages of servo-driven technology is the ability to achieve higher levels of precision and accuracy. With the constant feedback from the servo motors, the Servo Driven Horizontal Turning Center can make real-time adjustments to ensure that each part is machined to exact specifications. This capability is particularly beneficial in industries like aerospace, medical device manufacturing, and automotive, where parts need to meet extremely tight tolerances. Traditional turning centers, while capable of producing high-quality parts, often require additional manual adjustments and are more prone to wear and tear, leading to fluctuations in precision over time.

Another significant difference between these two types of turning centers is the efficiency and speed of operation. Servo motors in Servo Driven Horizontal Turning Centers are designed to be much faster and more energy-efficient than traditional drive systems. These motors can ramp up or down to the required speeds quickly and smoothly, providing a faster machining cycle and reducing idle times between operations. In contrast, traditional machines may experience delays when switching between speeds or adjusting feed rates. This increase in speed not only boosts productivity but also reduces energy consumption, as the servo-driven system only draws power when needed, making it more cost-effective in the long run.

The flexibility of a Servo Driven Horizontal Turning Center is another area where it outperforms traditional models. These modern machines are equipped with advanced CNC (Computer Numerical Control) systems, allowing for complex, multi-axis operations and the ability to execute a wide range of cutting tasks without the need for manual intervention. This capability is a significant advantage in a competitive manufacturing environment where companies need to adapt quickly to changing demands and produce a variety of parts with different shapes and sizes. Traditional turning centers may require more time to change tools or setups, limiting their versatility.

Moreover, Servo Driven Horizontal Turning Centers tend to have better stability and less vibration during operation. The precise control provided by servo motors ensures that the cutting process remains smooth, reducing tool wear and improving the finish quality of the parts. Traditional machines, on the other hand, may experience more vibrations and mechanical strain, particularly during high-speed operations, leading to more frequent tool changes and potential quality issues.

In terms of automation, Servo Driven Horizontal Turning Centers are also better equipped to integrate with other automated systems, such as robotic arms and conveyor belts, to streamline production processes. Automation is an essential feature in modern manufacturing environments where high-volume production is often required. Traditional turning centers may lack the advanced communication interfaces or flexibility needed for full automation, resulting in slower throughput and higher labor costs.

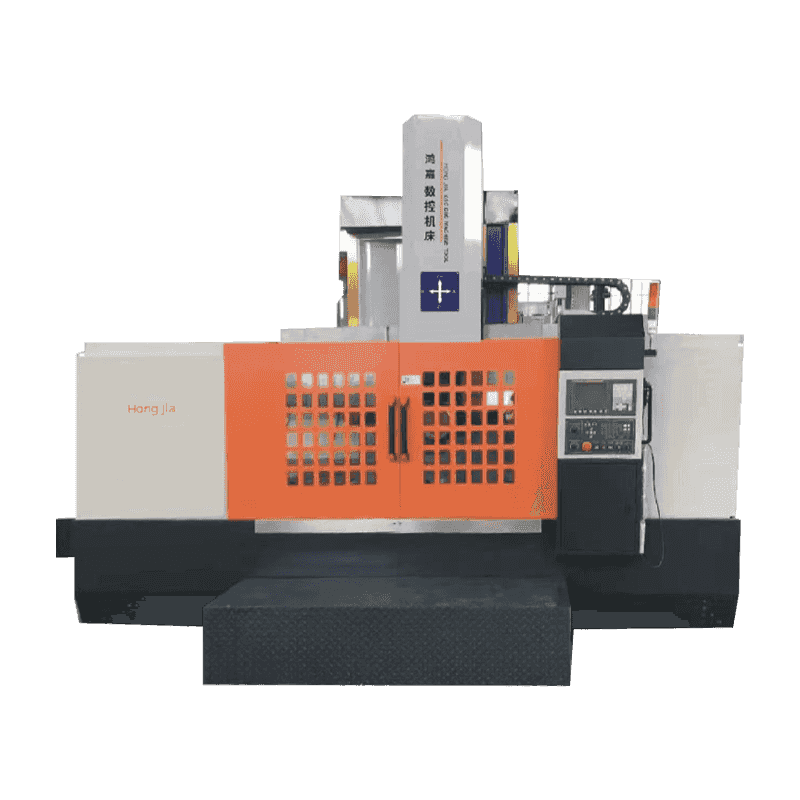

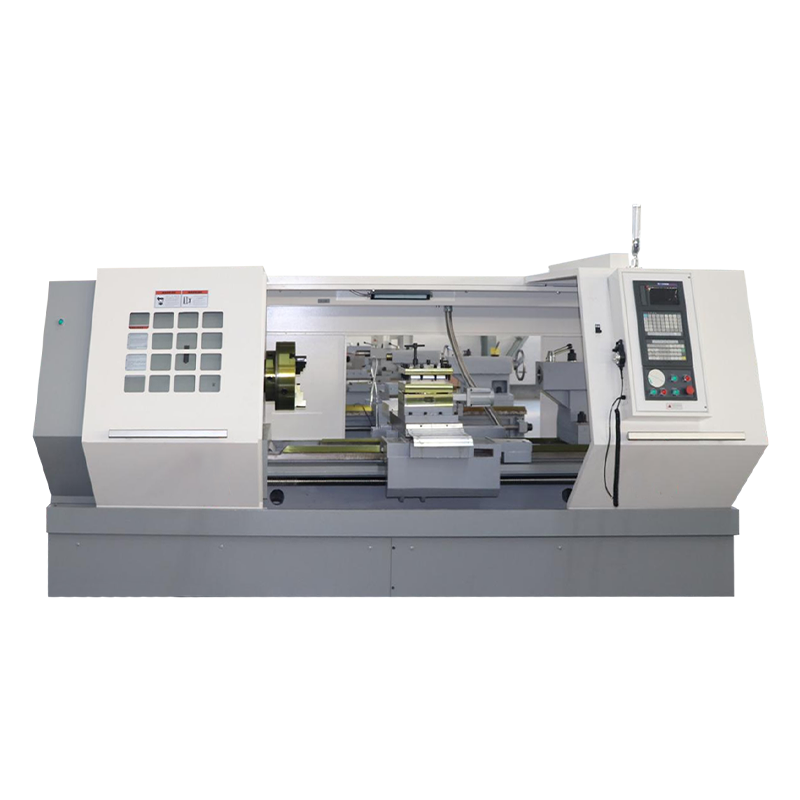

Recommended Products

Product

Contact Information

- Phone:

+86-13857478288

- Tel:

+86-574-86520206

- E-mail:

yp@hongjia-cnc.com

- Add:

No.287,Binhai Fourth Road, Hangzhou Bay New Area, CiXi City, Zhejiang Province

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى